Abana lies on Block OML 114, at the mouth of the Calabar River in Nigeria, in water 4.8m deep (7.6m deep at high tide). It was discovered by two exploration wells, drilled as part of a four-well programme. The first encountered a 50ft oil column beneath a gas cap. The second, drilled 3km along the strike, intersected a 56ft oil column.

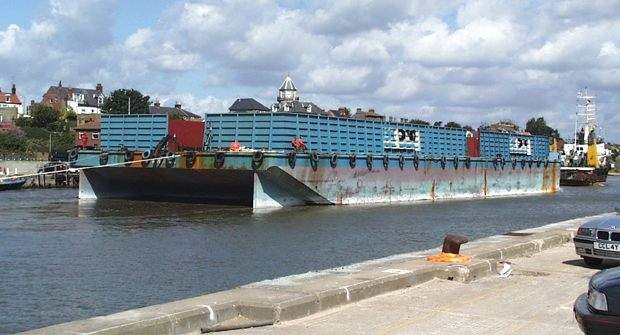

The flexible development plan envisaged production from horizontal wells, drilled from two surface locations. A process facility delivering fully stabilised crude oil for export was to be attached to one of the clusters. Expro was contracted to procure a newly constructed dumb barge and convert it into a moored floating production facility. The boat departed from Shanghai on a voyage via Singapore, through the Suez Canal, to Great Yarmouth.

The field is operated by Moni Pulo. Development on the field began in 1997 and the first oil from the field was produced in March 1999.

In 2007, production from the field declined by 32% from 2.42mmbbl to 1.62mmbbl.

This was due to a rupture in the export pipeline in December 2006. Production was shutdown for three months due to the rupture and was resumed in March 2007.

Barge

The barge is 90m in length and 25m wide. The conversion was based on packaged systems, integrated as pre-assembled units (PAU).

At Great Yarmouth, production equipment was installed, including a 50,000 barrels/day (BPD) oil-processing/export system; a 40,000BPD produced water-treatment system and a 52,500bwpd water-injection system. It has a 30 million ft³/day future gas-compression facility and a 40 million ft³/day gas flare and tower.

The power-generation facility consists of refurbished and tested gas turbines. The main power generation is provided by two 3.3MW turbines, a single 1MW diesel standby generator and a 400kW emergency generator. There is also a fuel gas steam generator.

Equipment

The process equipment is sufficient to ensure a BS&W of 0.5%. The water-injection system has an oxygen content of 30ppb and water is cleaned to 25ppm free oil in water, before disposal overboard. The water-handling system consisted of several PAUs, designed such that the package interfaces were minimised and full hook-up/testing was conducted prior to arrival in the field. The units included the possibility of the future retrofit of additional water-treatment facilities. The purpose built 40-man accommodation module is A60 fire rated as required and approved for use on the installation.

On deck there are two SOLAS 40-man enclosed lifeboats and a Hardy 24 workboat. The helideck can accommodate a Bell 212/s76c model or similar. Equipment movement is enabled by a hydraulic crane of an 8t capacity. The barge has its own oil-spill control equipment as well as a fire and gas system.

Mooring

A piled Dolphin system was chosen as the most suitable method for mooring. Using this, the two fixed jacket structures (Dolphins) with barge-guide frames supported by the dolphins, moor the barge in a fixed location but still allow it to pitch, heave and roll under changing water conditions. Fabrication was undertaken in Louisiana.

Transportation

During the conversion period, it was decided that the safest method of transporting the floating production facility (FPF) to the Abana location was by dry tow. This was achieved using the AMT transporter. The barge’s main process and accommodation facilities were subjected to a hook-up, prior to installation, to check interface, instrumentation and control systems.

Production wells

Nine horizontal production wells and two deviated water-injection wells have been drilled and tested from three surface cluster locations. The use of batch drilling methods resulted in the saving of $11m. Of the 86,000ft drilled by these wells, in excess of 23,200ft was drilled horizontally. Of the nine pilot holes drilled, five were from the Abana East cluster and four from Abana West. The entire project, which required the installation of a complete production infrastructure, was executed within 13 months of the contract being awarded.

In 2005, TransAtlantic Energy Solutions completed Phase IV drilling of the field. The company drilled one exploration well and five horizontal development wells. The project increased production at the field from 8,000 to 10,000bbls/d.