Askeladd development is a gas field development project in the Barents Sea on the Norwegian continental shelf. It is the second stage of the multi-phased Snøhvit development.

The project partners include Equinor (36.79%, operator), Total (18.4%), Petoro (30%), Neptune Energy (12%), and DEA (2.81%). The gas project was sanctioned for development with an investment of Nkr5bn ($641.5m) in March 2018.

Snøhvit’s plan for development and operation (PDO), including the multi-phased development, was approved in 2002.

Askeladd and Snøhvit developments will constitute a world record for the longest sub-sea to shore tie-back with a total length of 185km.

The Askeladd development is expected to commence production by the end of 2020.

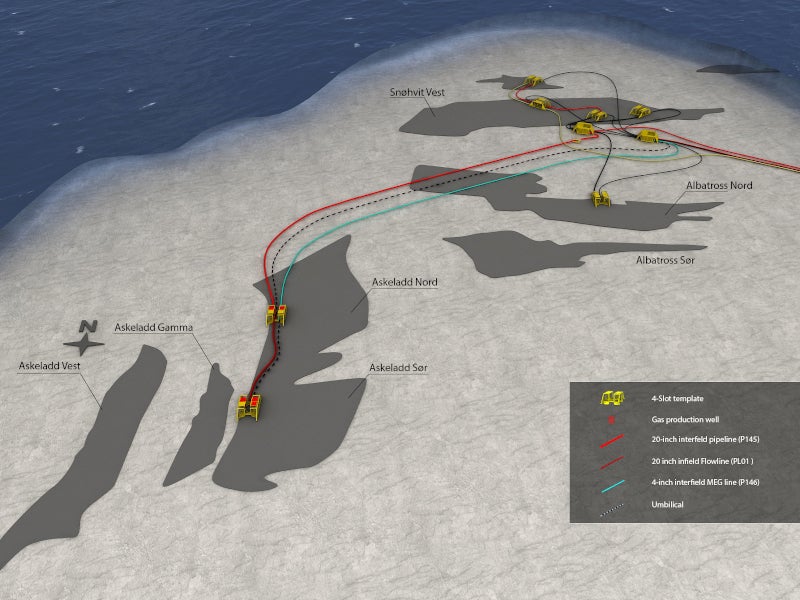

Location of Askeladd development

The Askeladd gas development is situated at a water depth of about 250m in the block 7120/8 in the Norwegian sector of the Barents Sea. The development includes the North, South, West and Gamma segments.

The field is located approximately 40km away from the Snøhvit development, 140km north-west of the town of Hammerfest. It is situated 180km from the Melkøya onshore LNG plant in Hammerfest.

Askeladd field discovery and appraisal

The Askeladd field was discovered by the 7120/8-1 wildcat well in 1981, proving gas in the Hammerfest basin.

The well was designed to analyse the presence of hydrocarbons in a seismic closure of the block, targeting a Middle Jurassic age sandstone. It encountered relatively dry gas at 2,092m and a gas column down to a water contact at 2,180m was identified through log analysis.

The appraisal well 7120/8-2 was drilled to a total depth of 2,590m in the western part of the Hammerfest basin. It discovered hydrocarbon presence in 2,081m-2,161m of sandstone sequences in the Stø formation. The second appraisal well, 7120/8-3, was drilled to a total depth of 2,335m to test the expansion of the Askeladden North structure. The well was abandoned as a dry well in 1983.

Askeladd development plan

The Askeladd development will comprise three wells via two new subsea templates with a total of eight well slots. It also has scope for developing more wells in the future. The plan includes drilling of one well in each of the North, Gamma, and South segments.

The development will also involve the installation of infrastructure which will be tied-in to the existing Snøhvit facilities.

A 20in-wide and 44km-long pipeline will tie Askeladd to the Snøhvit field. Other components of the infrastructure will include a 42km-long umbilical and a 35km-long, 4in-wide mono-ethylene glycol (MEG) pipeline.

The sub-sea production system will constitute two manifolds and four trees. The sub-sea manifolds will be installed using the Island Victory vessel’s two work-class remotely operated vehicles (ROVs) and an offshore crane.

The project’s support activities will be based in Hammerfest and other locations.

Gas export from Askeladd development

The Askeladd development is expected to supply 741.6 billion standard cubic feet (bcf) of gas and 12.5 million barrels of condensate to the Hammerfest LNG facility to maintain plateau production rate at the plant.

Natural gas produced from the Snøhvit field is sent through a 160km-long pipeline to the Hammerfest LNG facility for processing and then exported via LNG ships. The condensate, water and CO2 are separated from the well stream prior to cooling of the natural gas to -160°C and condensing to LNG. The separated CO2 is cooled to a liquid form before being sent back to Snøhvit to be injected in a separate formation under the seabed.

Contractors involved

Aker Solutions won an engineering, procurement and construction (EPC) contract to deliver subsea production systems and services, while Nexans was contracted to design, manufacture and deliver static infield and inter-field umbilicals with power, fibre-optic and hydraulic elements for the sub-sea production systems.

Ocean Installer will support the project throughout the development phase by providing services such as fabrication and installation works. It contracted Island Offshore for supplying its Island Victory vessel for sub-sea works. Subsea 7 received a contract from Equinor to perform pipelaying works.

Ramboll was selected to undertake a front-end engineering design (FEED) study for the pipelines linking Askeladd to the Snøhvit field.