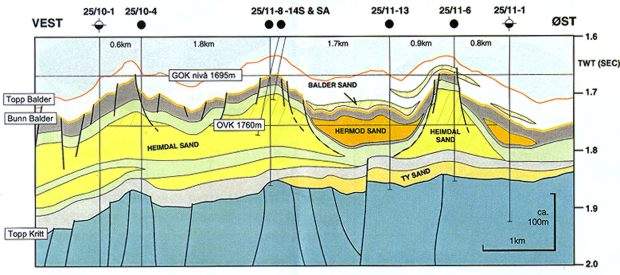

Balder is located in blocks 25 / 10 and 25 / 11, 165km west of Haugesund, in a water depth of 125m. The field was discovered in 1967, but it was only during the appraisal drilling in 1974 that the major part of the field was discovered.

Water depth in the area is 127m. ExxonMobil is the operator and sole licensee. The field’s licence period expires in 2028.

The company is also the 100% owner of Ringhorne fields. Ringhorne was tied-back to the Balder FPSO in early 2003 for processing and export.

The Balder field is in a decline phase although it is expected to continue producing until 2025. Various studies are being conducted to try to improve the oil recovery.

ExxonMobil Exploration and Production Norway is evaluating five new wells at Ringhorne and Balder, which are expected to start production by 2014. The company conducted 4-D seismic studies of the two fields between 2006 and 2009. A major drilling campaign of Ringhorne fields began in early 2011.

Balder reserves

The Balder field is estimated to provide recoverable reserves of 171 million barrels of oil and 0.8 billion cubic metres of associated gas. The reservoir is highly problematic because it has viscous oil, at a 20API specific gravity.

The field’s reservoir pressure is 177bar and the temperature is 77°C. Oil was discovered on the nearby Ringhorn (10km north) and Forseti (7km north) prospects, and oil and gas were found on the Hanz prospect (15km south).

Balder production

In 1991 the field produced 800,000 barrels of crude during a five-month extended well test using Golar Nor’s production ship Petrojarl 1.

Balder is one of first fields on the Norwegian continental shelf to be developed by means of a permanent floating production and storage (FPSO) vessel. During the production period the Balder FPSO will produce a total of 171 million barrels of oil.

Although Balder’s gas was initially reinjected Esso requested that the gas be subsequently routed through Statpipe. In October 2003, gas produced at the field was transported to Statpipe through the Jotun FPSO.

The field has 12 production wells, three water injection wells, one gas injection well and a water source well.

Water injection

To maintain pressure and enhance oil recovery produced groundwater from the water source well is injected into the reservoir.

Production vessel

The Balder FPSO contains the facilities required for the processing and storage of crude oil. The vessel is owned by Esso Norge and is 211m long and 36m wide. It has a storage capacity of 380,000 barrels of crude, which is offloaded via shuttle tankers connected temporarily to the production vessel’s stern.

Loading from the Balder FPSO can take place in a sea state with waves up to 5.5m in height. It can offload at a capacity of 31,500 barrels per hour. The Balder FPSO has ten crude oil tanks: eight located aft and two in front of the turret. In addition, it has a double bottom and double sides, as well as single longitudinal and transverse bulkheads. It is designed for continuous field operations for a minimum of ten years and is capable of operating in 70-100m water.

The FPSO processed about 47,300 barrels of oil per day (bopd) in 2010. About 19,200bopd came from the Balder field and 28,100bopd from Ringhorne.

Balder subsea system

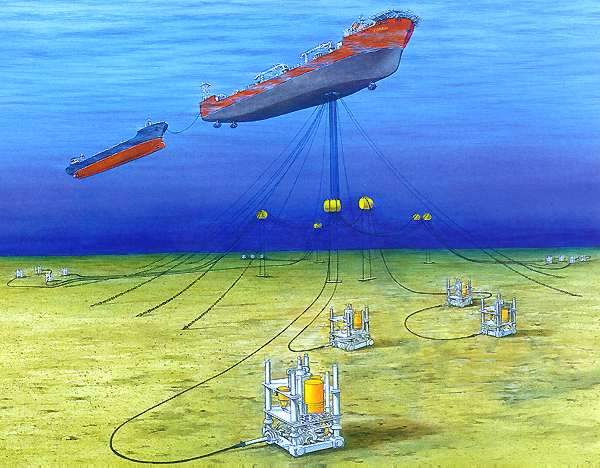

The subsea system selected for Balder consists of up to 15 subsea wells. Each well includes its own independent guidebase, wellhead system and subsea tree. Some of the production wells are commingled and share a common flowline and riser.

Wells are grouped at four field site locations with an electrohydraulic control umbilical from the Balder FPSO to each field site. The riser and flowline layout is designed to avoid interference with the FPSO’s mooring system.

All seabed-to-vessel lines – mooring lines and risers – pass through the turret, which is positioned just in front of midship. The vessel keeps stationary by means of ten anchors.

Process facility

The Balder processing facility is located behind the turret and has a peak capacity of 83,000bpd. The process facility includes a process train with a three-stage separation process.

All process and utility equipment are built as complete modules. This includes an oil separation and produced water-treatment system, compression and gas reinjection, power generation, water injection, oil metering, chemical injection, ventilation, heating and cooling systems and a flare.

The living quarters provide accommodation for 60 people. A power supply is provided from separate generators, using the produced gas or diesel as fuel.

Balder production start-up

The production vessel came onstream in September 1999 and is producing at a rate of 80,000-90,000bpd.