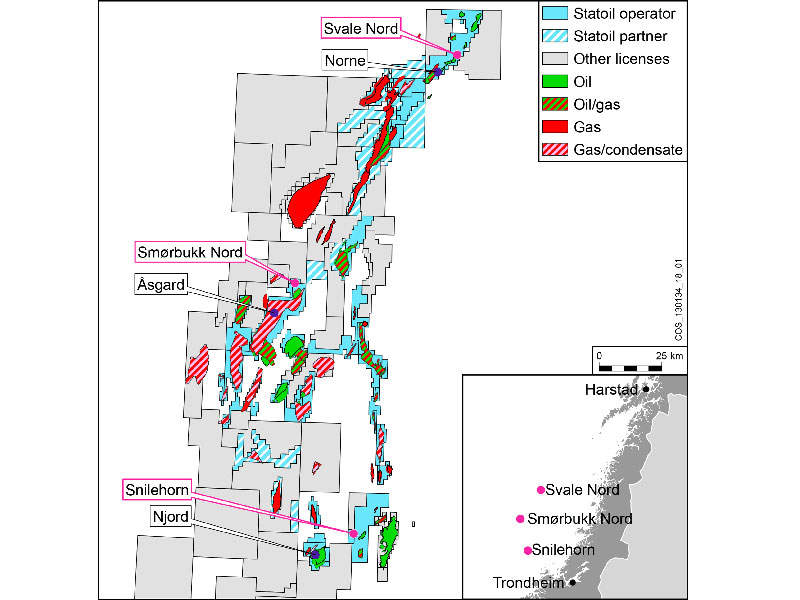

Bauge Field, formerly known as Snilehorn, is an oil field located in block 6407 / 8 of production license PL348 in the Norwegian North Sea.

The field lies in 282m of water, approximately 15km east of the Njord field and 15km west of the Draugen field.

Bauge Field is owned by Statoil Petroleum (35%), ENGIE E&P Norge (20%), Point Resources (17.5%), DEA Norge (17.5%), Faroe Petroleum Norge (7.5%) and VNG Norge (2.5%).

Ownership interests of ENGIE E&P and DEA Norge are expected to change to 10% and 27.5% respectively, pending government approval.

Statoil submitted the plan for development and operation (PDO) of the field in March 2017, and the same was approved in June 2017, Statoil will also serve as the site’s operator.

Bauge oil field discovery

Bauge field was discovered in November 2013 by the 6407 / 8-6 wildcat exploration well, which was drilled to test the early-to-Middle Jurassic age reservoirs in the Åre and Tilje formations.

The discovery well was drilled to a depth of 3,420m, and the discovery was the first to prove oil in the Grey-Beds formation.

A 130m-thick oil column was encountered in the Tilje formation, while a 40m-thick oil column was struck in the Ile formation.

The well also encountered a 21m-thick oil column in the Triassic Grey-Beds formation.

Appraisal on the Bauge oil field

A side-track appraisal well, 6407 / 8-6 A, was drilled to further evaluate the discovery.

The well was drilled to a depth of 3,537m, and encountered a 6m-thick oil column in the Melke formation, a 75m-thick oil column in the Ile formation and a 43m-thick oil column in the Tilje formation.

Both the discovery and appraisal wells were drilled by the Songa Trym semi-submersible drilling rig.

Bauge field geology and reserves

Bauge is part of the Halten Terrace area of the Norwegian Sea, which is characterised by a number of fault compartments and seismic anomalies.

The field is estimated to contain 73 million barrels of oil equivalent.

Bauge offshore field development details

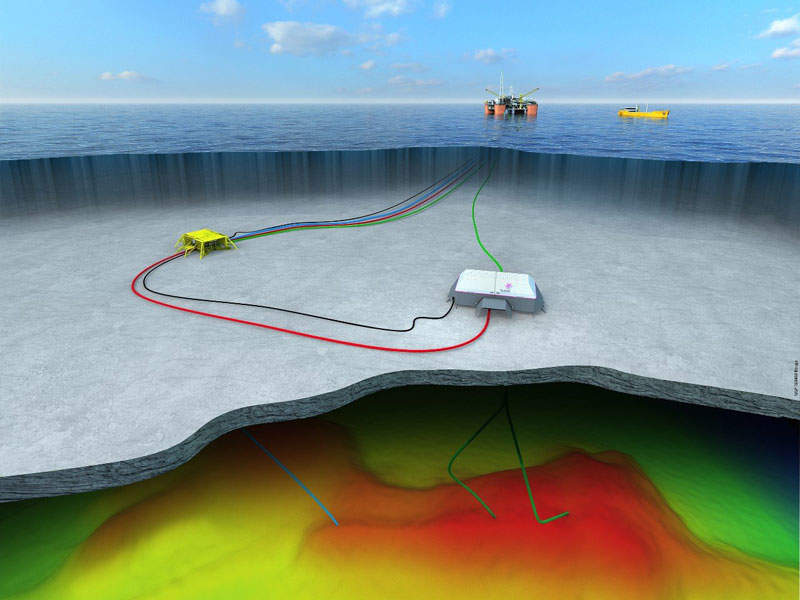

The Bauge field is planned to be developed as a tie-back to the Njord A platform, with first production expected in 2020. The estimated cost of developing the field is NOK4.1bn ($482m).

Statoil will deploy its next-generation Cap-X subsea production system for the first time at the Bauge field.

The production system will include one subsea template, two oil production wells and one water injector.

Hydrocarbons recovered from the field will be transferred to the Njord A platform.

Tie-in of the Bauge field is expected to prolong the life of the Njord field by approximately three years.

Statoil is upgrading the Njord infrastructure at a cost of NOK15.7bn ($1.82m) as part of the Njord Future project.

The upgrade will extend the life of the infrastructure by another 20 years and facilitate the development of new and satellite fields in the area, including Bauge.

Details of Statoil’s Cap-X subsea system

Statoil initiated development of the Cap-X technology in 2013, in order to increase the efficiency and recovery of resources in the Barents Sea.

The majority of the reservoirs in the Barents Sea are located at shallow depths, which means drilling of horizontal wells at the field is more challenging than those found in deeper depths. The cost of drilling and recovering oil from the reservoirs increases as a result.

Statoil developed the Cap-X technology to tackle the problem and reduce costs by roughly 30%.

A key feature of the technology is a suction pile shaped like an upturned cylindrical steel bucket, which also comes pre-installed with a drilling conductor.

The technology allows for multiple wells to be closely spaced above reservoirs, which provides cost savings during both installation and production.