The Blake Flank project is located at the Outer Moray Firth, in the North Sea, around 64 miles from Aberdeen, UK. The structure adjoins the main Blake channel structure and was commenced in June 2001.

The field was developed into two phases. Under phase 1, the Blake channel was developed, which involved the construction of six production wells and two water-injection wells, and tying-back the same via the project’s existing facilities to the Ross FPSO vessel.

The project reported an aggregate average field rate of 16,225bopd for 2008.

Under phase 2, the Blake Flank, which involved two production wells and an injection well, was developed. The first production from the field was in September 2003 with an estimated flow rate of 5,200bopd.

The project reported an aggregate average field rate of 16,225bopd for 2008.

Blake channel

The main Blake reservoir, a thick channel sand, is estimated to contain recoverable reserves of 50 to 75 million barrels of light oil. The original Blake discovery well, 13 / 24b-3, was drilled by BG International in March 1997 and tested sweet 32º API oil at a maximum flow rate in excess of 2,600bpd on a 40 / 64in choke.

It was the first well to be drilled by BG on block 13 / 24b, which was awarded in the 14th UK licensing round in 1993.

Three other appraisal wells in block 13 / 24 were drilled in 1998, one of which was tested at 4,000bpd. The 13 / 29b-6 well drilled in 1999 was tested at 3,950bpd. In addition, it also confirmed the south extension to the project.

Drilling of the first of the eight wells began in April 2000, with the installation of subsea facilities carried out in early 2001. The hydrocarbons produced from the individual wells at the Blake field are transported via flowlines to a subsea production manifold for onward transportation to the Bleo Holm via 10in and 12in production lines.

On the FPSO, the Blake fluids are processed with those from the Talisman-operated Ross field, 9.5km away. The produced oil, gas and water will be separated on the Bleo Holm and the oil temporarily stored onboard prior to export by shuttle tanker. The surplus gas will be exported via the existing 24in Frigg UK pipeline to the St Fergus gas terminal. An average daily rate of 5,700t or 40,000bbls was achieved in 2001.

Blake Flank development

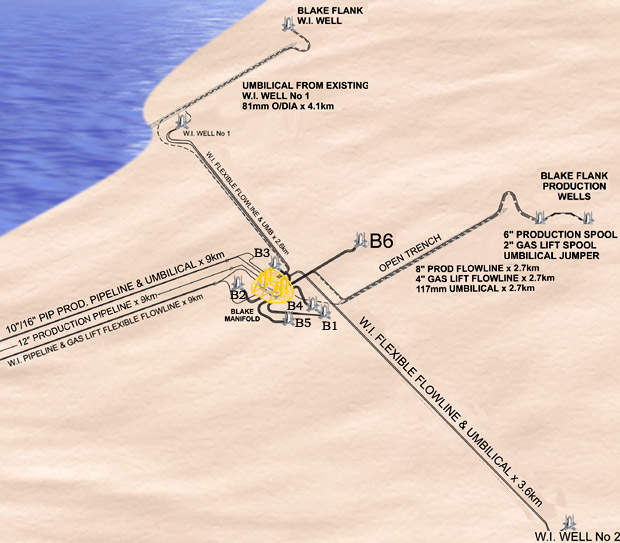

In November 2002, approval of the £60m Blake Flank development was granted by the UK Department of Trade and Industry. The field is operated by BG International on behalf of its partners Talisman Energy and Paladin Resources. It was developed by two production wells and a single water injector tied into the existing Blake production manifold.

The appraisal well on the Blake Flank was spudded in September 2001, and was followed by the testing of two zones and a sidetrack programme.

Tests at the first zone, over the Coracle Formation, flowed 2,450bpd on a 56 / 64in choke. The second test was designed to determine the productivity of the overlying Captain sands; it flowed 3,000bpd on a 1in choke.

Blake Flank contracts

The subsea controls contract was awarded to Kvaerner, and that for subsea Christmas trees to Cameron Cooper. Technip Offshore UK was awarded a fast-track engineering, procurement, installation and commissioning contract for the subsea installation elements.

The contract, worth €15m (£10m), included the tie-back of two subsea production wells and one water injection well to the existing Blake production manifold in the Blake development.

Technip Offshore UK undertook the project management, engineering and design, manufacture and installation of three flexible flowlines, one for water injection (6.5in, 4km), one for production (8in, 2.7km) and the last for gas lift (4in, 2.7km), and two electro-hydraulic control umbilicals (2.7km and 1.4km).

Fabrication of the flexible flowlines was undertaken at Technip-Coflexip’s Le Trait manufacturing facility in France, and the umbilicals were manufactured under a separate contract by Technip-Coflexip subsidiary DUCO in Newcastle, UK. All trenching and pipelay work was carried out by the offshore support vessel Normand Pioneer. The tie-ins and testing were carried out by the diving support vessels, CSO Orelia and CSO Marianos.

Reserves are estimated at 20 million barrels over ten years.