Blind Faith is located in approximately 7,000ft of water at Mississippi Canyon blocks 695 and 696 in the Gulf of Mexico. It is operated by Chevron with a 62.5% working interest on behalf of Kerr-McGee with a 37.5% working interest. Total capital costs

for the project have been put at around $900m.

The field was discovered by Chevron in June 2001 when drilling in the Miocene sands using Diamond Offshore’s dynamically positioned semisubmersible rig Ocean Confidence. In between 20,900ft and 24,300ft, the well encountered more than 200ft of

net pay. This well was followed by an appraisal well was drilled in 2004. Total reserves have been put at up to 100 million barrels of oil equivalent.

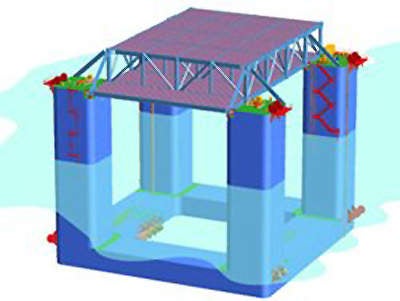

The Blind Faith development is based on a subsea system tied back into a deep draught floater.

The contract for the trees and controls was won in an EPC contract by FMC. There are three type EHXT – HC trees a super-heavy-duty 30in mandrel wellhead connector, standing in a water depth of around 2,120m (6,950ft). A feature of the field is

the extreme downhole environments and the trees can therefore withstand pressures up to 15,000psi.

The trees are connected to a four-slot manifold secured to the seabed by suction piles. The manifold has round trip pigging and the overall system is pre-engineered to allow downhole gas lift. Control is provided by three 8,000ft-long umbilicals. The

umbilical is designed with collapse-resistant hoses to handle the high temperatures and pressures. They are subject to external pressure requirements of 6,000psi, and maximum umbilical operating pressure is 15,000psi.

BLIND FAITH DRILL CENTRE

The field development is based on a production drill centre in Mississippi Canyon block 696 in approximately 6,950ft of water. This is tied back to a semisubmersible host facility in Mississippi Canyon block 650 by means of two insulated

flowlines.

The flowlines including the associated Pipeline End Terminations (PLETs) and pre-laid Steel Catenary Risers (SCRs) were laid by Subsea 7’s vessel Seven Oceans.

FLOATING PRODUCTION

The production uses a semisubmersible floating facility which was designed by Aker Kværner under an EPC contract. The semisubmersible hull left the Aker Kværner Verdal yard in Norway on 24 June 2007, and has been transported to a Gulf of

Mexico integration yard to be outfitted with the topsides.

The development was the first to use Aker Kværner’s four-column ring pontoon Deep Draft Semisubmersible (DDS) concept, conceived for the application of steel catenary risers in the ultra-deepwater and current-heavy Gulf of Mexico environment. It

was transported using the HLV Tern from Dockwise as transport vessel.

The topsides fabrication began fabrication in 2006 at Gulf Island Fabrication.

Connecting the seabed facilities to the platform, Aker Kværner has supplied an 9,500m advanced dynamic steel tube umbilical, including all surface and subsea terminations. The engineering and manufacturing was done in Mobile, AL, following a

detailed dynamic analysis.

Aker Marine Contractors will install the Blind Faith platform using the specialised offshore construction vessel BOA Sub C.

Export will be carried out by Williams Energy, which will extend its Canyon Chief and Mountaineer pipelines by 37 miles each. Both of these pipelines were placed in service in May 2004 to support production from the Devils Tower Field at Mississippi

Canyon block 773.

Initial production is expected to be approximately 30,000bpd and 30mmcf/d. The semisubmersible facility will have a production capacity of approximately 45,000bpd and 45mmcf/d. The topsides can be upgraded to a capacity of 60,000bpd and 150mmcf/d to

accommodate production from satellite discoveries or third-party tiebacks.