The Brae Bravo platform, a part of the Brae Area oil field in the UK North Sea, is being decommissioned. It is operated by Abu Dhabi National Energy Company (TAQA), a government-controlled energy group based in the UAE.

The platform was previously operated by Marathon Oil UK, a subsidiary of American exploration and production company Marathon Oil. British oil and gas firm RockRose Energy acquired the UK business of Marathon in 2019 and had to transfer the operatorship of the platform to TAQA after joint venture (JV) partners JX Nippon and Spirit Energy initiated legal action against RockRose over its financial stability.

More than 500 offshore works are expected to be involved during the peak phase of the North Sea decommissioning project.

Brae Bravo decommissioning background

The decommissioning of the Brae Bravo topsides and flare jacket was approved by the Offshore Petroleum Regulator for Environment & Decommissioning (OPRED) in August 2018.

Before the start of the major decommissioning works, cleaning and make safe works on the platform were completed in 2019, following which the platform was down-manned and awarded the normally unattended installation (NUI) status.

Brae Bravo platform location and details

The Brae Bravo platform is located in a water depth of 99m in the North Brae area within block 16/07a in the UK section of the North Sea, approximately 269km north-east of Aberdeen, Scotland.

The Brae Bravo platform came on stream in April 1988 and the production from the platform ceased in early-2019. It comprises a 22,000t jacket and topsides with a combined weight of 36,000t. The platform has a steel jacket/sub-structure and its flare comprises a second steel jacket/sub-structure, flare tower, and a steel connecting bridge to the platform.

The topside modules include drilling and production facilities as well as utilities placed in three tiers. The lowest tier comprises the module support frame (MSF) that forms the interface between the topsides modules and the jacket/sub-structure of the platform. The facilities that make up the second tier include the wellheads, production and export facilities, accommodation and utilities.

The third tier constitutes the rig-skidding module and derrick, injection compressor, drilling modules, generators and switchgear, accommodation, storage facilities and a helideck atop the accommodation modules.

Brae Bravo platform decommissioning details

The Brae Bravo platform decommissioning is being executed in three phases with the final decommissioning works expected to be completed in 2022.

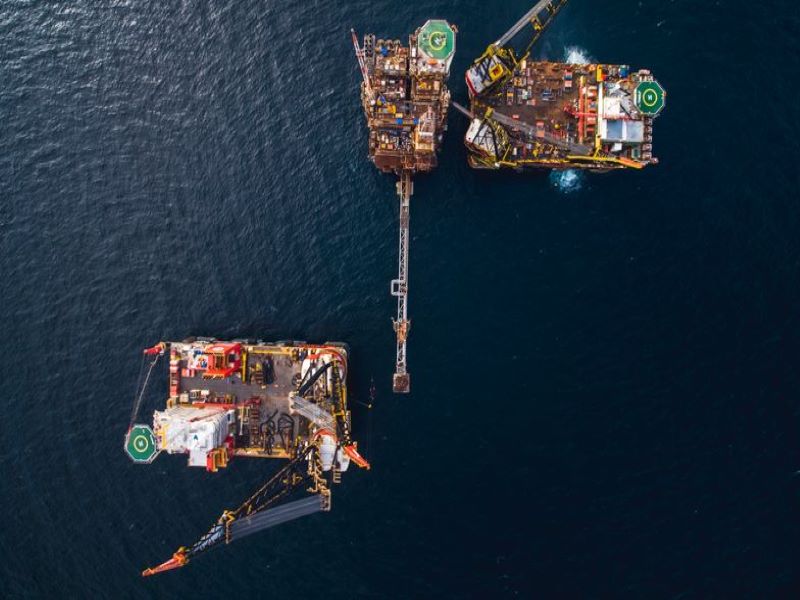

The decommissioning programme for the Brae Bravo platform will use two of the world’s largest semi-submersible crane vessels (SSCVs), Thialf and Sleipnir.

The first decommissioning campaign, which commenced in April 2021, involved Thialf and Sleipnir which are working simultaneously in the Brae field to prepare and remove the flare tower, bridge, and jacket. The Thialf semi-submersible crane vessel is currently completing the preparatory works and module separation for a final removal that will happen during Summer 2021.

The second campaign will involve the Sleipnir vessel removing the remaining topsides which will be completed in two trips to the field during Summer 2021. The only remaining component of the platform at the end of the second trip will be the top of the jacket above sea level.

The remaining structure will be fitted with a dedicated navigational aid and a 500m safety area will be maintained until the completion of the jacket decommissioning programme in 2022. The waste generated from the decommissioning process will be transported to demolition contractor AF Environmental Base’s facility in Vats, Norway, for further processing and recycling with an estimated reuse or recycling target of 95%.

Contractors involved

A consortium of Heerema and AF Offshore Decom was awarded the contract to implement the decommissioning project in September 2018.

Heerema owns and operates the Thialf and Sleipnir semi-submersible crane vessels.