The Brage field lies in the northern part of the North Sea at a depth of 140m. The field is situated in blocks 31/4, 31/7 and 30/6 and primarily contains oil, along with minor quantities of gas.

Statoil is the operator of the field with 32.7% interest. Partners include Talisman Energy Norge (33.84%), Faroe Petroleum (14.25%), Core Energy (12.25%), VNG Norge (4.44%) and Spring Energy Norway (2.5%).

First production occurred in 1993. The peak production was achieved in 1998 at 120,000bpd. Current production is 25,000bpd.

Discovery

The Brage field was discovered in 1980 through the discovery well 31/4-3.

Oil reserves

As of December 2010, Brage contains recoverable reserves of 56mscm of oil, 3.9bscm of gas and 1.3Mt of natural gas liquids (NGL). The oil is of 33.7° API and contains 0.37% of sulphur.

Geology

The Brage field reservoir is made of the Statfjord Formation of early Jurassic age and the Brent Group and Fensfjord Formation of middle Jurassic age. Oil and gas are also found in the Sognefjord Formation of late Jurassic age.

The field reservoirs are located at a depth of 2,000m-2,300m.

Field development

Basic engineering works commenced in 1990. The plan for development and operations was approved in 1991. Five production wells were drilled to commence oil recovery from the field.

In 2008, a production well was drilled into the Bowmore structure as part of an infill and exploration drilling programme to improve oil recovery from the field.

An ultra long reach water injection well into the Bowmore structure and a production well in the Fensfjord formation were drilled in 2009. Towards the end of 2009, a new production well was drilled into the Statfjord formation. The well was completed and commenced production in 2010.

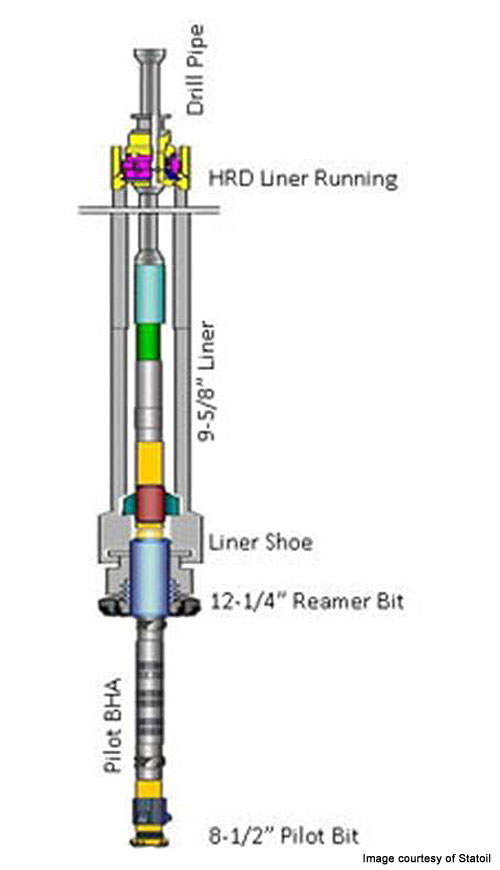

In 2009, Statoil tested a new technique on the Brage field which helps in improving drilling operations in unstable formations similar to those found in the field. The technique, officially known as steerable drilling liner (SDL), was developed in-house in collaboration with Baker Hughes.

Production

Production from the Brage field commenced with five wells tied back to the Brage platform. Oil is recovered from the Statfjord and Fensfjord formations through water injection. Oil recovery from the Brent Group formation commenced in 2008 through water injection. Gas injection into the Sognefjord formation commenced in March 2009.

Brage is currently in the tail phase of production although new wells have been drilled in 2010 to improve oil recovery. The field is expected to cease production in 2015.

The partners are planning to drill new infill wells in 2012 and are working on finding ways to increase oil recovery.

Addition of chemicals to injection water to improve water flow is being considered as one option. Another method being considered is microbiological injection (MEOR).

Brage platform

The field uses a fixed production, drilling and accommodation facility called the Brage platform. The platform features a steel jacket and a two stage separation unit which contains gas compression / export facilities.

The platform is equipped with a drilling unit for the drilling of additional development and exploration wells to improve oil recovery from the field. The drilling unit enables the platform to be used in the development of adjacent prospects.

Export

The recovered oil is sent via a pipeline to the Oseberg A platform. From the platform it is sent via the Oseberg Transport System (OTS) to the Sture terminal in western Norway.

The recovered gas is transported through a pipeline to Statpipe, which distributes it in different markets.

Contracts

In 2006, Aker Kværner was awarded a contract worth NOK150m to upgrade the water injection system on the Brage platform. The upgrade helped in improving oil recovery by boosting pressure in the reservoir. It also ensured zero emissions from the produced water.

KCA DEUTAG was awarded a NOK900m contract in 2006 to drill production wells on the Brage platform. The contract also included provision for two, two-year extensions. In February 2010, Statoil awarded one of the two-year extensions to KCA DEUTAG.

Under a new maintenance programme undertaken at the Brage field, Statoil has contracted DNV to document the maintenance programme. DNV will document the programme using the Reliability Centred Maintenance (RCM) and Life Cycle Cost (LCC) standards.

Pipetech provided its high pressure water technology for cleaning the flowlines, caisson and cooling channels at the field.