The Buzzard field is located in the Outer Moray Firth, central North Sea, 100km north-east of Aberdeen, UK, and 55km from the coast at Peterhead.

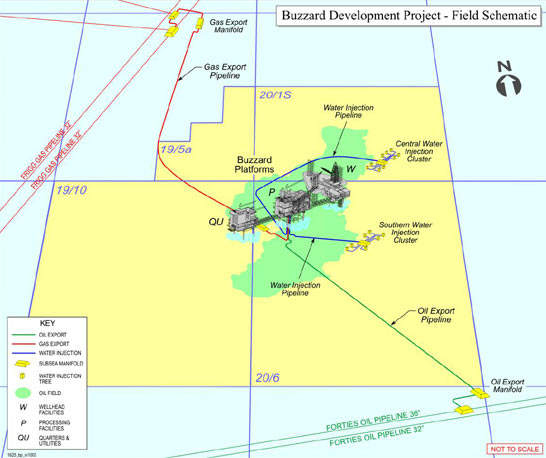

The field straddles two licences – P.986 (blocks 19 / 10 and 20 / 6) and P.928(S) (blocks 19 / 5a and 20 / 1S. The water depth in the area is approximately 100m.

The field is operated by Nexen with 43.21254% (Nexen acquired Encana in 2004) on behalf of PetroCanada (29.89122%), BG (21.73307%) and Edinburgh (5.16317%).

Buzzard discovery

In June 2001, The Buzzard field was discovered using the semi-submersible Ocean Nomad, which initially encountered a 400ft gross oil column.

The oil column tested at 6,547bpd and 1mcfd of gas. A subsequent sidetrack extended the oil-bearing sands 4,400ft to the east and increased the gross oil column to 750ft.

The high-quality Upper Jurassic turbidite reservoir lies within a stratigraphic trap 7,800ft to 9,175ft below mean sea level.

Geology and reserves

The Buzzard reservoir has a low gas / oil ratio and required pressure maintenance through water injection from the onset of production. The reservoir also features excellent rock quality with up to 360ft of high-porosity, high-permeability sands with an oil saturation of up to 94%. The oil consists of medium sour crude (32.6° API, 1.4% sulphur) with minor wax and asphaltenes.

The field’s total recoverable reserves are estimated at more than 550 million barrels of oil.

Gross production was expected to reach a plateau of 180,000 to 190,000 barrels of oil a day between 2007 and 2008.

At the end of April 2008, production almost halved due to the closure of the Forties pipeline in the Central North Sea – the result of a 48-hour refinery strike.

The development required an investment of £1.491bn. Production was restored to full rates of between 200,000boed and 220,000boed in February 2010.

Offshore platforms

The Buzzard field was developed by three bridge-linked steel platforms supporting the wellhead facilities (W), production facilities (P), a platform supporting accommodation and utilities (UQ) and a fourth oil stripper platform (PS).

The wellhead platform is a four-leg jacket, featuring an integrated deck with conductors and wellhead trees. The production platform is a four-leg jacket with fluid processing equipment, water injection pumps and gas compressors. The UQ platform is also a four-leg jacket supporting the integrated deck and accommodation, lifeboats, helideck and seawater lift pumps.

In September 2010, the fourth platform was installed at the field. The platform features a 6,500t deck and bridge structure supported by a 3,500t jacket.

Buzzard’s production wells

The Buzzard development may include up to 27 production wells. Eight wells were pre-drilled and available for a production start in December 2006. This drilling was undertaken by a skid-mounted jack-up rig located adjacent to the wellhead platform.

As of 2011, 21 wells were drilled, of which 16 are available for production.

Reservoir pressure is maintained by an active waterflood programme using produced water supplemented by treated seawater when necessary. Under the base case, 16 water injection wells will be drilled through two subsea manifolds located about 1km from the platforms.

Four were pre-drilled and available at the time of production start-up. It is anticipated that infill wells will be drilled to improve production in late-field life.

Oil and gas transportation

An oil transportation agreement was signed with BP to export oil from Buzzard via the nearby Forties Pipeline System to Cruden Bay and then onto Hound Point. An 18in pipeline was laid from the Buzzard processing platform to the nearest point in the Forties System, approximately 28km away.

An agreement was signed with Total and Elf to export surplus gas via the Frigg system. A 10in pipeline was laid from the Buzzard location to the Captain ‘T’ point on the UK Frigg pipeline, 29km away. From there the gas is transported to the St Fergus Gas Terminal.

Production start

In the first quarter of 2007, the Buzzard field produced 85,000 barrels of oil equivalent a day. Forties Blend crude oil changed in quality during January 2007, when crude oil from the Buzzard field began production through the FPS system.

Although there are over 50 other fields making up Forties Blend, Buzzard is now the largest component field and it altered the hydrocarbon characteristics of the blend. The latest BP assay sampled in April 2007 shows Forties Blend to have an API of 41.8° and a sulphur level of 0.49%. This is with a Buzzard composition in the Blend of approximately 22%.

Gas import

On the basis of the reservoir, as it is now known, it is likely that the platform will become gas deficient for power generation in the next five to seven years and will then need to import gas.

The agreement with the Frigg UK Pipeline owners provides for the supply of fuel gas at that time as required, as well as for commissioning and start-up.

Contracts for Buzzard

CB&I designed the platform with Aker Verdal constructing the jacket structures. The wellhead platform was built by BIFAB in Scotland.

Burntisland Fabrications won the contract for the management, fabrication and provision of assistance with commissioning of the 3,650t wellhead deck, constructed at the company’s facilities at Burntisland and Methil.

Heerema was awarded the contract for the management, fabrication and provision of assistance with the commissioning of the 9,500t utility deck.

Dragados carried out the management, fabrication and provision of assistance with commissioning of the 10,000t production deck at Cadiz, Spain.

The pipelines and field infrastructure was installed by Saipem of Italy.