Cassia Compression project involves the development of the new Cassia C platform, approximately 57km off the south-east coast of Trinidad.

The project is owned and operated by BP Trinidad and Tobago (BPTT), a joint venture (JV) between British multi-national oil and gas company BP (70%) and Spanish energy firm Repsol (30%). The Cassia C is the 16th offshore facility of BPTT. The project is crucial to maintain a stable gas production in Trinidad and supply to downstream consumers and liquefied natural gas (LNG) producing company Atlantic LNG.

The Cassia Compression project is a part of BPTT’s Area Development plan, which represents the company’s course of action for the development of its resources in the Columbus Basin. BPTT made the final investment decision (FID) on the project in December 2018.

The Cassia Compression development is projected to access one trillion cubic feet (tcf) of resources. The first production from the Cassia C platform is expected in 2022.

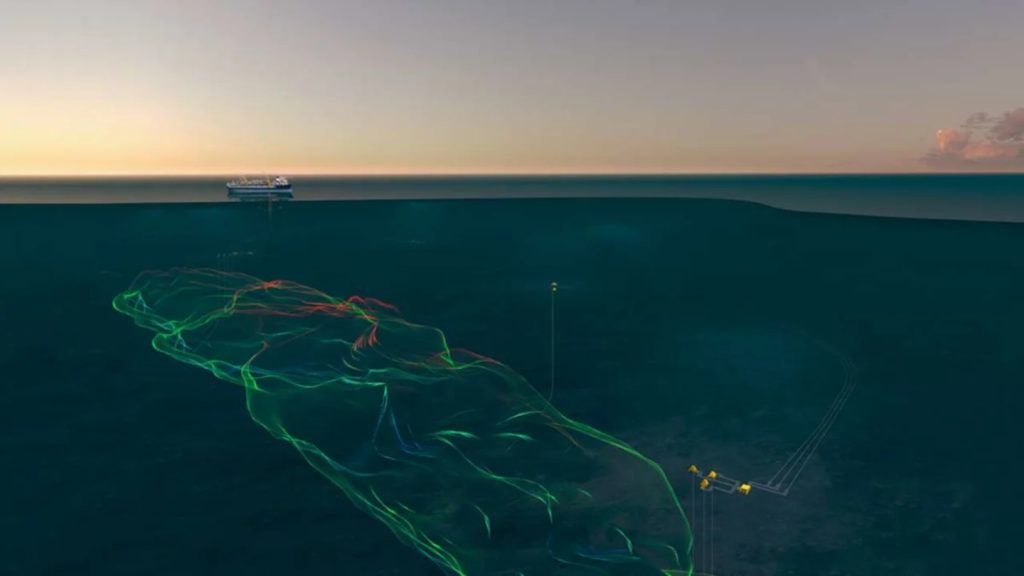

Cassia field geology

The Cassia gas field, which came on stream in May 1983, is a broad half-anticline containing limbs with dips. The sediments in the gas field comprise sand and shale packages related to the Mayaro, Gros Morne, or Palmiste formations.

Cassia C platform development details

The 3,747t jacket for the Cassia C platform was installed using Heerema’s semi-submersible crane vessel Sleipnir in 2020.

Thialf, a semi-submersible crane vessel operated by Heerema, was deployed for the installation of the platform, including an 8,928t topside, followed by a 793t bridge and flare structures. The installation of the platform was completed in July 2021.

The Cassia Compression project also includes brownfield modifications at the existing Cassia B platform located adjacent.

Cassia C platform operations

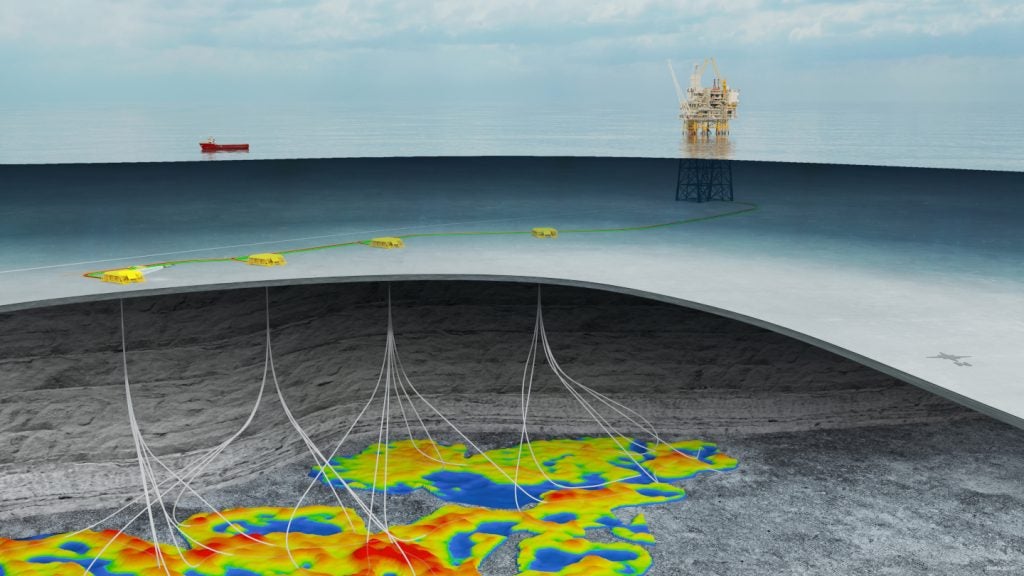

The Cassia C platform will be utilised to compress the gas produced from the low-pressure gas reserves of the existing fields in the Greater Cassia Area in the Columbus Basin. It will allow BPTT to maximise recovery from the existing resources. The Cassia C, with a production capacity of 1.2 billion standard cubic feet of gas a day (bcfd), will be the third platform in the Cassia complex.

The platform will receive hydrocarbon gas through new pipes from the Cassia B platform situated across the bridge in a water depth of 223ft. Three gas turbine-driven compressors at the platform will compress the gas before returning it to Cassia B for export.

The liquids from the Cassia C and Cassia B platforms will be combined and boosted before exporting.

Technology used at the platform

BPTT will utilise an integrated control and safety system (ICSS) to remotely manage the operations of the platform. The system will be based on Experion® Process Knowledge System (PKS), Honeywell’s flagship control system. PKS will combine an advanced automation platform and innovative software applications for advanced safety, efficiency, and digital security at the platform.

McDermott’s digital twin technology, which is based on its Gemini XD software platform, will be used for efficient gas compression at the platform. The technology is expected to deliver production efficiencies throughout the project lifecycle.

Contractors involved in Cassia Compression project

US-based engineering and construction company Fluor was awarded a contract to provide front-end engineering design (FEED) services for the project in 2017.

Multi-national engineering firm McDermott received the contract for the engineering, procurement, construction, hook-up, and commissioning of the Cassia C topsides, jacket, and bridge in January 2019. The project’s compression platform was fabricated and constructed at McDermott’s fabrication facility located in Altamira, Mexico.

The jacket and bridge landing frame of the platform were fabricated by a local firm named Trinidad Offshore Fabrication Company (TOFCO) at its yard in La Brea.

Dutch marine services provider Heerema Marine Contractors supplied the crane vessels for the installation of the platform while global technology firm Honeywell provided the ICSS control system for the platform.

The Cassia Compression project is being developed by BP Trinidad and Tobago as a part of its Area Development plan.