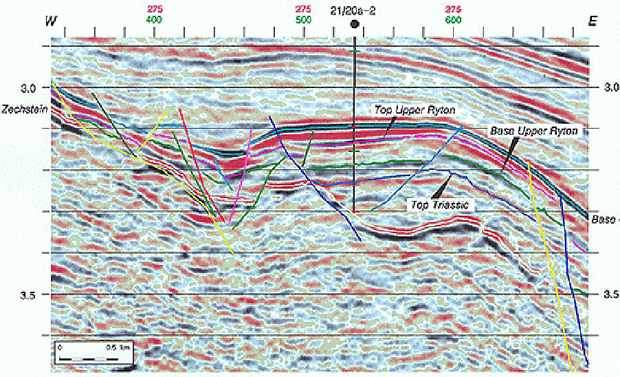

The Cook Field comprises an oil trap in a simple domal structure, formed by salt at depth. A single exploration well, 21/2Oa-2, has been drilled into the structure, down-dip of the crest.

Oil is trapped in a single sandstone reservoir, of late Jurassic age, with an oil / water contact defined in the discovery well without a gas cap.

The Cook structure measures approximately 2km x 2km and dips to the NW and NE by faulting to the cast and sand-pinching, towards the south-west.

The southern part of the structure known as ‘Cook South’ has more development risks than the Cook Main core area closer to the 2112Oa-2 well. Thus, the Cook two-well development plan is centred on Cook Main.

Reserves

The oil has a gravity of 35° API. The reservoir is highly over-pressured, with an initial reservoir pressure of 9,7OOpsi and a bubble point of approximately 3400psia.

The peak oil rate is expected to be 20,000b/d, with reserves put at between 12 and 23 million bbl of oil and l5 BCF of gas. Field life is four to five years.

Development scheme

The recovery mechanism used for the development is natural depletion. The scheme requires up to two near-vertical, subsea production wells; one available at first oil and, if necessary, the second approximately one year later. Gas-lift capability is included in the production wells in the event of water production.

The Cook subsea trees will be dual bore, rated to a maximum working pressure of 10,000psi, which is suitable for the maximum wellhead shut-in pressure of 6,700psi. The trees will be installed with flow bases and locked into the wellheads using 183 4in 10,000psi hydraulic connectors.

The wells will be connected to the Cook drill centre using rigid spools. A manifold structure will be positioned on the seabed to carry terminations for the well controls, pipelines and valves.

Production from the wells will be commingled at the manifold and flow through a cooling loop. They will then enter a single 8in line within a carrier pipe, to Anasuria. A 3in utility line will carry methanol to the wells from Anasuria at the start of field lift. In the later years, the utility line may be used to carry lift gas to the wells.

A single control umbilical will be installed between the Teal cluster and the Cock manifold. The umbilical will supply hydrate, wax, scale and corrosion-inhibition chemicals.

At the Anasuria riser base manifold, the wellstream enters the Anasuria turret via a 6in flexible pliant wave riser (a second pliant wave is used for methanol or gas lift going the other way). The wellstream will be fed into an existing separator, which will be dedicated to Cook. This separator is large enough to act as a slugcatcher.

Gas from the Cook separator will be mixed with Teal and Guillemot A gas for treatment, compression, metering and export. A portion of Cook gas will also be used as fuel.

The contract specified that the riser pull-in operations had to be diverless and the flexible risers had to be installed while the Anasuria was live.

The decision to use the Apache to deliver the pipe-in-pipe made this the first reeled line of its kind in the North Sea.

Installation

The pipeline was installed under an EPIC contract from Coflexip Stena Offshore Limited (CSOL), using the Apache reelbarge. This was the first time that pipe-in-pipe was installed in such a way in the North Sea and it was carried out in two journeys.