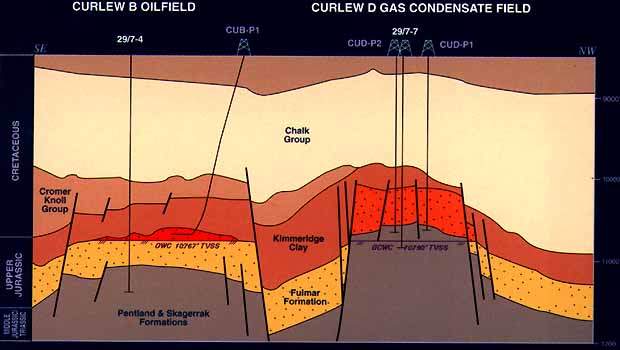

the Curlew field is located in the Central North Sea, 210km east of Aberdeen, UK, in block 29 / 07. It consists of two accumulations, discovered in 1990 and 1994, in 92m of water.

The Curlew B and Curlew D reservoirs are located in the western Central Graben of the North Sea, 10,000ft to 10,800ft below the seabed, in the Upper Jurassic layer.

Curlew development strategy

The £300m Curlew field fast-track development involved converting an existing tanker into a floating production storage and offtake (FPSO) facility. The Maersk Dorset, originally built at the Odense Steel Shipyard in Denmark, was selected for conversion into the 100,000t Maersk Curlew. This was leased from the MAS Production Company, a business division of Maersk.

Maersk subcontracted the conversion work and associated production facilities to the MAS Alliance (a joint venture between AMEC, SBM and Maersk Contractors) on an engineering, procurement, installation and construction (EPIC) basis. The tanker was converted at A and P Tyne, on the River Tyne, while the fabrication, construction and installation of the topsides was carried out by AMEC. The mooring turret was supplied by SBM.

An overhaul of the mooring system of the Curlew FPSO was undertaken in May 2009. Maersk signed a contract with DOF Subsea UK to carry out the project. The scope of work for DOF included the replacement and inspection of the existing onshore and offshore mooring chains, clump weights and wires with new systems. DOF chartered the Olympic Zeus vessel for the project.

Maersk awarded a $650,000 contract to HB Rentals in September 2009 to supply three cabins for the Curlew FPSO. The cabins include two accommodation modules with a capacity of 12 and two engineering modules for use as offices.

Subsea layout

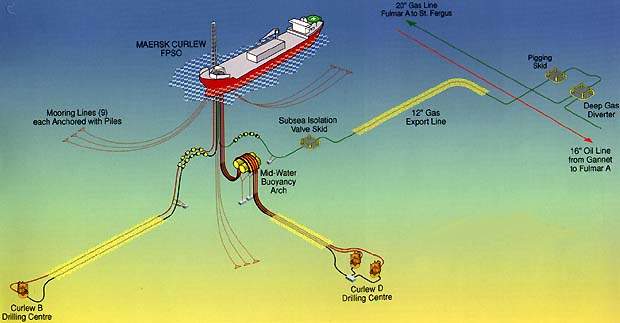

The subsea facilities include two drilling centres over the Curlew B and Curlew D accumulations, located 2.4km to the south-west and 1.6km to the south-east of the vessel.

Curlew D is tied back to the FPSO by two 8.25in production flowlines, while Curlew B is connected by a 5.5in production flowline. The wells are controlled via electro-hydraulic umbilicals. All pipelines and umbilicals were trenched.

Curlew turret

The lines enter the Maersk Curlew via the turret-mooring system. This allows the vessel to weathervane, while production fluids from the subsea wells are transferred from the pipeline risers, through the swivel, then into the vessel’s production facilities.

The turret is held in position by nine mooring lines secured to the seabed by piles.

Curlew topsides

Topsides facilities on the vessel, for processing the production fluids, include separation, dehydration, metering and gas-compression systems. These process facilities are located on a number of deck modules, 3.8m above the main vessel deck, in order to achieve safe separation from the storage tanks.

The system comprises a single three-stage separation train and a test separator. During normal operations Curlew D is routed to the first-stage separator, whereas the lower pressure Curlew B wellstream flows directly into the second-stage separator. After stabilisation, the crude is further de-watered in an electrostatic coalescer and stored in the cargo tanks until metered and exported via shuttle tankers. Produced water is discharged overboard after removing the oil with hydrocyclones.

The gas is compressed in three stages in a gas-turbine-driven compressor and dehydrated using a tri-ethylene glycol (TEG) contactor. A regenerator allows the glycol to be re-used, minimising environmental impact and cost. The gas is exported through an export gas pipeline to the deep gas diverter, where it ties into the Fulmar Gas Line. A small volume of this gas is used as fuel for the turbine-driven power generation and gas compression, and to fire the FPSO’s boiler.

The utility systems, such as power-generation, separate the process area from the temporary refuge to minimise risk to personnel.

Export

Export shuttle tankers initially visit every ten days to take delivery of the oil, although the storage capacity of 560,000 barrels allows production to continue for longer periods, such as during adverse weather conditions.

The gas export system comprises 500m of 10.2in ID flexible gas export riser linked to a subsea isolation valve. This is connected to a 12in, 27km gas export pipeline.

Curlew C

A third development in the block, Curlew C, was brought onstream in September 2008. Discovered in 1993, about 6km east of the Maersk Curlew, it has a single development well tied back to the FPSO.

Curlew’s development marks the first time Shell has produced hydrocarbons from a chalk formation in the North Sea, and peak production is expected to be about 25,000boepd.

Processed oil is transported by tanker while gas is exported through the Fulmar gas line to St Fergus.