The Dai Hung oilfield lies at a water depth of 361ft offshore Vietnam. The field is located in block 05.1Ab 265km south of Ba Ria-Vung Tau province. The capacity of the field is 6,300bopd and 4.32mmcfd. The estimated life of the field is until 2025.

Petrovietnam Exploration Production (PVEP) is operator of the field and owns a 50% interest. Vietnam Oil and Gas Group (PetroVietnam) owns the remaining stake.

Discovery

The Dai Hung field was discovered by Mobil Oil & Gas in 1974. The company did not undertake appraisal or development activities. In 1986, Vietsovpetro took over the field’s development.

In 1993, Vietsovpetro signed a production-sharing agreement with a BHP Petroleum-led consortium to develop the field. The consortium consisted of several international oil companies. The agreement marked the beginning of the first phase of development of the Dai Hung field.

Discovery and development

The Dai Hung field was discovered by Mobil Oil & Gas in 1974. The company did not undertake appraisal or development activities. In 1986, Vietsovpetro took over the field’s development.

In 1993, Vietsovpetro signed a production-sharing agreement with a BHP Petroleum-led consortium to develop the field. The consortium consisted of several international oil companies. The agreement marked the beginning of the first phase of development of the Dai Hung field.

Phase I

BHPP drilled seven appraisal and development wells. Four of the seven wells were completed as production wells by August 1994. First production from the field began in October 1994. Two additional wells were drilled and completed by early 1995.

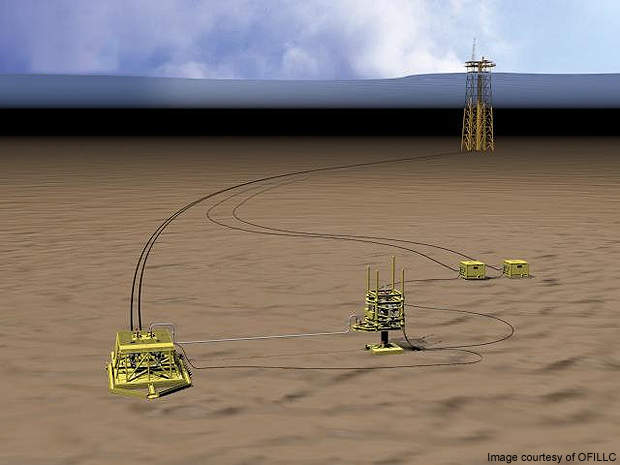

Eleven wells were drilled for oil to be drilled from the field; two were used for water injection. All the wells were tied-back to Dai Hung I FPU (FPU-DH1) through two flow-lines and one umbilical.

In 1999, the BHP consortium withdrew from the project, citing difficulties in the development of a deepwater field, the distance of the field from the shore and the need for complex subsea technologies, as reasons for withdrawal.

Vietsovpetro handed over the development of the field to PVEP. PVEP was appointed as the operator of the field in 2003.

Phase II

The Vietnamese Government approved the second phase of development in 2007. It included drilling three new wells, and the installation of a fixed wellhead platform, Dai Hung Well Head Platform 1, with 12 slots for drilling. The new wells were tied-in to the platform and FPU-DH1 through flowlines and umbilicals.

PVEP signed a seven-year loan agreement for $200m with VietinBank in May 2011 for the expansion of the field. The expansion plan is part of Vietnam’s efforts to increase national oil production due to declining oil production rates from ageing fields.

In June 2011, a second wellhead platform called WPH-DH2 was installed at the field. The new platform became operational in August 2011, tripling the field’s production to 11,600bopd. Along with the platform, five wells were brought into production as part of a plan to increase the field’s output to 18,000bopd.

Geology

The Dai Hung field lies in the South Con Son basin and features a complex subsurface structure. It contains several stacked reservoir sequences with the granitic basement located at a depth of 2,600m at the shallowest portion of the field. Clastic sediments of 800m thickness lie above the basement, over which lies a 200m-thick carbonate platform.

Dai Hung I floating production unit

The Deepsea Pioneer semi-submersible FPU was converted for use at the Dai Hung field. The FPU was originally designed by Aker Engineering and constructed at a shipyard near Invergordon in Scotland.

The FPU-DH1 has a crude oil processing capacity of 40,000bpd and a natural gas processing capacity of 55Mmcfd.

The length of the hull is 355ft and its width is 221ft. The FPU-DH1 features an eight-point mooring with a 4in chain. It can accommodate 80 people and features two 42t National Pedestal cranes.

Hikari Orient floating storage and off-take vessel

The 232,000dwt Hikari Orient tanker was converted into a soft moored FSO for use at the Dai Hung field. The conversion, carried out by Tanker Pacific, saw the addition of a Sigrist oil-in-water unit, and renovation of the accommodation facilities and cargo system.

Catenary anchor leg mooring buoy

Oil produced from the field is processed on the FPU-DH1 and transported to the Catenary anchor leg mooring buoy located 2km from the field. From the buoy, the oil is loaded onto the Hikari Orient FSO for storage. The oil is later transferred to shuttle tankers for transportation onshore.

Contracts

In February 2010, PVEP signed a $65m contract with Vietsovpetro to build and transport the WPH-DH2 platform.

In March 2010, PetroVietnam Technical Services Corporation was awarded a $57m contract to install subsea equipment connecting WPH-DH2 with FPU-DH1. PTSC designed, fabricated and installed three 2.2km of flexible flowlines and two 2.3km of export flexible flowlines.

It also installed two 4.8km of insulated flexible flowlines and a 6km subsea cable from WHP-DH2 to FPU-DH1. PTSC replaced two 2.3km flowlines and umbilical.

J Ray Reels, a unit of J Ray McDermott, was the main subcontractor for the project. In 2009, Aker Solutions won a $5m contract to supply undersea equipment for Dai Hung field. Aker will design, fabricate and install one horizontal undersea tree and other equipment. FMC Technologies provided subsea trees, subsea wellhead systems and other services during the first and second phase development of the field.

FMC Technologies provided subsea trees, subsea wellhead systems and other services during the first and second phase development of the field.