Dalia was discovered in 1997, 135km offshore in water depths of between 1,200m and 1,500m. The launch of Dalia, which came onstream in late 2006, was a significant step in the development of block 17, where 15 earlier discoveries have been made. It followed the development of nearby Girassol, brought onstream in late 2001, and Jasmim, a Girassol satellite.

By repeating Girassol, but on a much larger scale and under even more extreme conditions, Dalia boosts production on this golden block to around 500,000bpd. In total, the development of the Dalia project represents an estimated investment of over $4bn.

The production in December 2006 was over 200,000bpd. It is expected to increase to 240,000bpd. The proved and probable reserves are around one billion barrels.

The concessionaire of block 17 is Sonangol. TotalFinaElf has a 40% interest in block 17 along with Esso Exploration Angola (block 17) Ltd (20%), BP Exploration (Angola) Ltd (16.67%), Statoil Angola block 17 AS (13.33%) and Norsk Hydro (10%).

Dalia field development

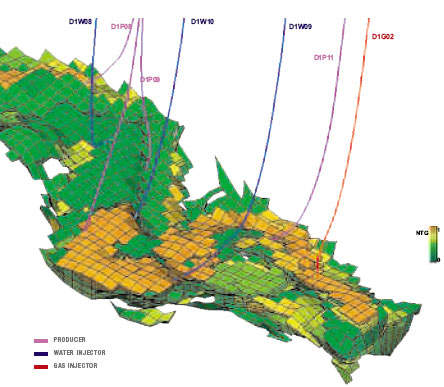

The Dalia development plan calls for production from the field’s three main reservoirs, as well as the adjacent Camelia reservoir.

These were formed more than 25 million years ago by the accumulation of sediment at the mouth of the Congo River.

The reservoirs lie not very far (about 800m) below the seabed, forming reservoirs that contain a viscous (between 21° and 23° API) oil at relatively low temperatures of between 45°C and 50°C.

Associated gas is not be flared but reinjected, thus contributing to maintaining the pressure of the field.

Together with the other block 17 partners, the group has designed one of the largest deep-offshore developments anywhere in the world. This is based on a subsea production system of 67 wells – 34 production wells, 30 water injection wells and three gas injection wells – with an option to extend to 71 bringing additional reserves. Further, by 2006, the number of wells increased to 71 and the field had 37 production wells and 31 water injection wells while the number of gas injections remained same.

These have been drilled with two rigs, Pride Africa and Pride Angola, in tandem for the initial 18 months of the campaign, which requires a toal of 2,500 days.

Dalia production

Plans envisaged 21 of the 67 wells on-stream by first oil, including 5.5in and 7in completions, seven smart completions and horizontal drains extending for an average of 1,100m.

The wells are highly deviated, for example, they are almost horizontal in the reservoirs. One major aspect of the well programme is the large-scale use of horizontal Christmas trees designed to allow wells to be drilled through them.

The wells are tied into nine manifolds feeding 40km of 12in production lines in four production loops; eight flexible risers using Integrated Production Bundle technology.

These take the fluid up to the surface facilities; four 35km of 12in water injection lines and risers as well as two 10km of 12in for the gas. There will also be 75km of umbilicals.

Dalia FPSO

The FPSO vessel for Dalia constitutes a second pole of production on Block 17. Capable of processing 240,000bpd, the Dalia FPSO has a storage capacity of two million barrels of oil.

The FPSO vessel, built in South Korea, has a hull dimension of 300m in length, 60m in breadth and stands 32m high. On top of this is 29,400t of topsides, including I-tubes.

It has a water injection capacity of 405,000bpd, water treatment capacity of 265,000bpd and gas compression capacity of 8mscf per day. The total installed power capacity is 66MW.

The living quarters can accommodate up to 120 people and up to 190 during shut-downs. The structure has a design working life of 20 years.