The Dongfang 13-2 gas fields development project involves the development of high-pressure and high-temperature gas fields located in the South China Sea.

Owned and operated by China National Offshore Oil Corporation (CNOOC), the project is part of the company’s $12.7bn investment programme to bring the Dongfang fields into production along with the Stampede, Weizhou 6-13, and Penglai 19-3 oil fields.

Development of the Dongfang 13-2 and other gas fields will enable China to meet its growing demand for energy. The project is expected to produce 43,400 barrels of oil equivalent per day at peak.

Dongfang 13-2 gas fields location

The Dongfang 13-2 gas fields are located in the Yinggehai Basin of the Beibu Gulf of Western South China Sea. The fields lie at a water depth of approximately 70m, southwest of the Dongfang 13-1 gas field.

Dongfang 13-2 gas fields discovery and reserves

The Dongfang structure was discovered in 2012 by the DF13-2-1 discovery well, which was drilled to a depth of 3,168m.

The discovery well encountered 35m-thick gas pay zones and flowed at an average rate of 42.4 million cubic feet of natural gas a day during the testing phase.

The Dongfang gas fields are estimated to hold 100 billion cubic metres of gas reserves.

Dongfang 13-2 gas fields development details

The field development plan for the Dongfang 13-2 gas fields involves the drilling of 30 production wells and installation of one central platform and two wellhead platforms.

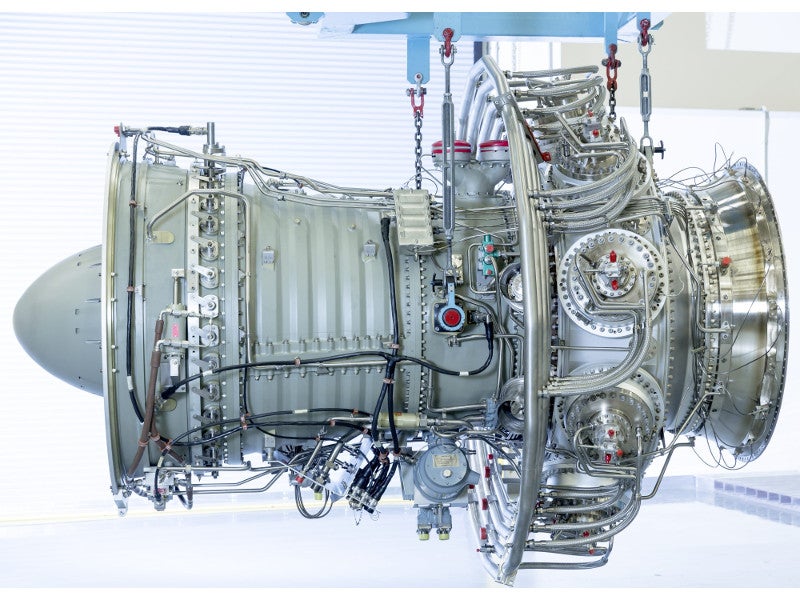

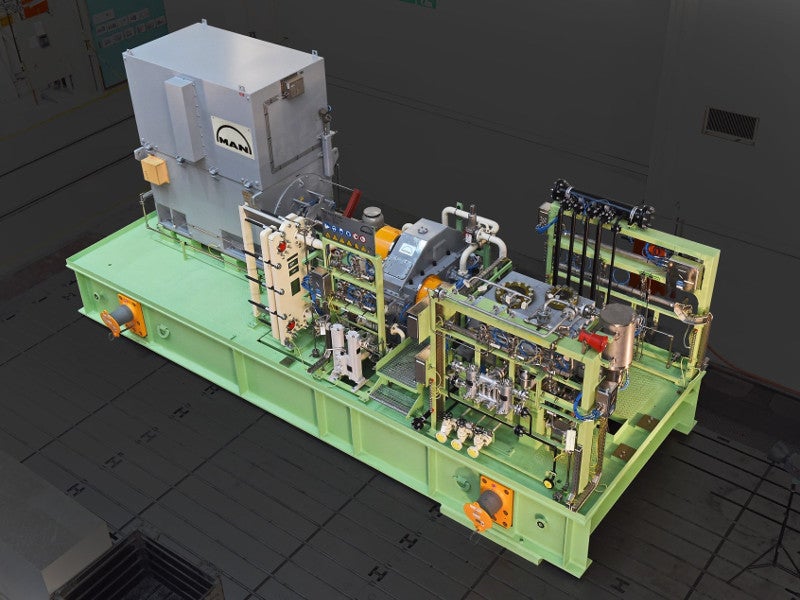

The platforms will be located 132km west of Dongfang City and will be installed with three wet gas and three dry gas compressor trains for gas reinjection and export, in addition to three SGT-600 power generation trains of 25MW each.

The gas compressor trains with intercooled barrel-type compressors will run on electric motors with a variable frequency converter, while the wet gas compressor trains will be manufactured in the form of standardised and modularised upstream packages.

One wellhead platform was delivered to the field location in October 2018, while the central platform assembly is expected to be completed in 2019.

Transportation of produced oil and gas

The gas produced by the fields will be transported onshore by four submarine pipelines totalling 223.8km in length. One of the pipelines is 195km long, making it the longest submarine pipeline laid independently in China till date.

The pipelines include two single-layer stainless composite pipelines and gas transmission pipelines with a diameter of 18in, one oil transmission pipeline with a diameter of 24in, and one gas transmission pipeline with a diameter of 6in.

Subsea pipeline laying for the project began in September 2017 using the deep-water pipe-laying crane vessel Offshore Oil 201, which is the first deep-water pipe-laying crane vessel of China. It has a single-day pipe-laying speed of up to 4.02km/day with an operating water depth of 3,000m.

Installation of subsea infrastructure related to the project was completed in October 2018. A total of 23 subsea structures were installed for the project.

Contractors involved

Fluor was contracted for the installation, loadout and commissioning of the central and wellhead platforms.

MAN Diesel & Turbo was contracted to supply six compressor trains, while Dresser-Rand, a part of Siemens Oil and Gas, will supply three power generation trains. The core components for the power generation trains will be supplied by Dresser-Rand, while the auxiliary systems will be supplied and packaged by Harbin Guanghan Gas Turbine.

CNOOC Engineering and COOEC Subsea Technology performed the deep-water pipe-laying operations.