The Echo-Yodel gas and condensate field, which is located in a water depth of 140-160m, offshore North West Shelf of Australia will be decommissioned.

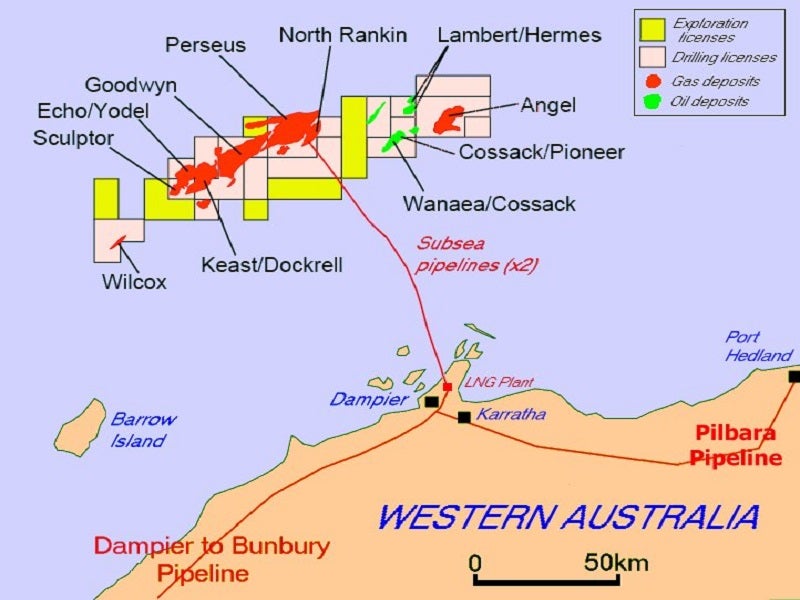

Operated by Woodside Energy, the first gas from the field flowed in December 2001 at a production flow rate of 350 million cubic feet per day (MMcfpd). Located 23km away from the Goodwyn A platform, the field forms a part of the North West Shelf project, the first liquefied natural gas (LNG) project of Australia.

Woodside is one of the participants in the A$34bn ($21.99bn) North West Shelf project along with BHP Billiton Petroleum, BP Developments Australia, Chevron Australia, Japan Australia LNG, and Shell Australia.

The company suspended the production from the two wells of the Echo-Yodel field in the second quarter of 2012. The environmental plan for the proposed plugging and decommissioning was submitted to the National Offshore Petroleum Safety and Environmental Management Authority (NOPSEMA) for evaluation in April 2020. Decommissioning activities are expected to begin between the first and third quarter of 2021.

The subsea infrastructure of the Echo-Yodel field is no longer required for the production activities of North West Shelf project, leading to the decommissioning of the field.

Echo-Yodel gas field details

The Echo-Yodel field lies in the Dampier sub-basin, within the production licence area WA-23-L in Commonwealth waters.

The field contains two horizontal producer wells, Yondel-3 and Yondel-4, which were responsible for the development of the Yodel Lower E reservoir in 2001.

Yondel-3 and Yondel-4 are subsea satellite wells, connected to the Goodwyn A platform, an integrated drilling, production, utilities and accommodation platform, via a 23km-long, 12in-diameter pipeline. The two wells are approximately 2km apart from each other and are connected to the 12in pipeline through short 10in spools.

A 23km-long, 5in-diameter electro-hydraulic umbilical connects the Goodwyn A platform to the subsea wells via short jumper flowlines.

Production suspension details of the field

Woodside Energy undertook a well suspension programme to suspend the production from Yondel-3 and Yondel-4 wells using a vessel-based light well intervention (LWI).

Under the LWI, a rigless technology was utilised, which was supported by dynamically positioned intervention vessel and a remotely operated vehicle (ROV). The system allowed entry to the wellbore without direct contact with the well. Production was suspended by installing two wireline plugs in the wells.

Decommissioning details of the Echo-Yodel gas field

The decommissioning of the Echo-Yodel field will include permanent plugging and abandonment of Yodel-3 and Yodel-4 wells, as well as the permanent abandoning of the Echo Yodel infrastructure in-situ. The permanent plugging of each well will require from 20 to 60 days.

The Echo Yodel infrastructure includes the existing pipeline, umbilical, the production wells with wellheads and X-mas trees, two umbilical termination assemblies, one infield umbilical termination basket, two infield jumpers and one pipeline inspection gauge launcher.

The infrastructure will render hard substrate to support the marine growth and local ecological functions. The company will also decommission the Capella-1 exploration wellhead under the project, which lies approximately 40km away from the Echo Yodel infrastructure.

The waste generated during the activities will be transported onshore for recycling or disposal purpose.

Vessels required for decommissioning

The decommissioning activities will require a moored semi-submersible mobile offshore drilling unit (MODU) for plugging and abandonment activities. A support vessel and anchor handling vessels will also be utilised under the project. About two to three vessels will be required for plugging activities.

A 500m radius petroleum safety zone will be made temporarily around the MODU during the plugging activities. The programme will also involve the creation of a 4,000m operational area radius around each well.