The Hoover Diana fields are located in the Gulf of Mexico, 160mi (258km) south of Galveston.

Diana covers several lease blocks, but is largely contained within East Breaks (EB) blocks 945 and 989 (also covering EB 946 and EB 988).

Hoover is located in the Alaminos Canyon blocks 25 and 26. The field was discovered in 1990 and successfully appraised in 1997.

The Diana appraisal well established a water-depth record of 4,657ft for testing from a moored vessel. This well also recorded maximum flows of 4,800 barrels.

Hoover was discovered in January 1997, 15mi east of Diana. The two fields contain estimated recoverable reserves exceeding 300 million oil-equivalent barrels.

Rig

For these subsea development wells and subsequent drilling programmes, Exxon will use a newbuild Marine 700 semisubmersible drilling rig from Marine Drilling Companies (MDCO).

The Marine 700 is a fourth-generation semisubmersible drilling unit of the Bingo 8000 design.

It is classed by DNV as a column-stabilised drilling unit and is Panamanian flagged. It is capable of operating in water depths ranging from 230ft-5,000ft.

The semisubmersible rig is designed for a maximum wave height of 32m (105ft) and a wave period of 11 to 15 seconds.

Box-type elements and transitions provide a minimum of stress concentration at critical connections and an adequate fatigue life of 20 years, based on North Sea criteria.

The semisubmersible has a transit draught of 9.75m (32ft), an operating draught of 23.75m (77.9ft) and a survival draught of 21m (68.9ft).

It has an overall length of 119m (390.4ft) and an overall width of 71.4m (234.25ft).

Development

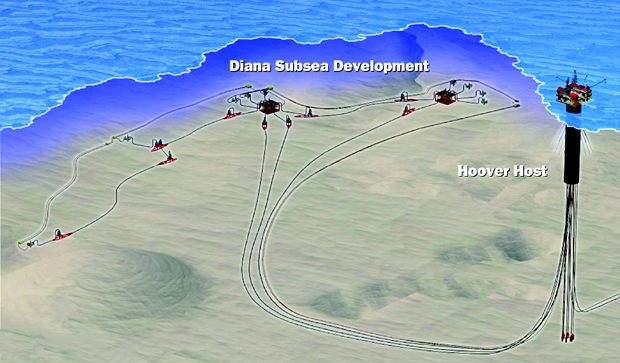

The development scenario envisages the Diana reservoir being drained from a six-well subsea development, which will be tied back to a deep draft caisson vessel (DDCV), located over Hoover in 4,800ft (1,463m) of water.

Deep draft caisson vessel

The Hoover DDCV consists of a cylindrical hull buoyed with air-filled compartments in the upper portion of the hull, which was ballasted with seawater and fixed ballasts in the bottom compartments.

On top of the steel hull, the DDCV production facilities are designed to handle 100,000 barrels per day of crude, 325 million cubic feet per day of gas and produce up to 60,000 barrels per day of water.

A three-level deck will house separation, dehydration and treatment facilities, as well as a drilling rig.

Surface trees on the DDCV are similar to trees found on traditional platforms.

All valves and flowlines are at the surface, located in the wellbay area of the DDCV.

In this particular application, the trees have tensioned risers that connect the surface trees to the well at the seafloor.

Surface trees allow for wellbore intervention, using conventional workover technology.

Mooring

The deep draft caisson vessel is moored via 12 anchor lines, which extend in a radial pattern from the hull.

The mooring lines will be 7,100ft long and will connect to piles driven into the sea floor, approximately 6,900ft from the DDCV at a lateral distance of about 5,100ft.

The mooring lines are taut, but will have some flexibility and form a catenary between the hull and ocean floor.

Each mooring line consists of chain in the top and bottom sections and spiral-strand wire rope in the middle section.

Installation

The installation of the DDCV was carried out in 1999.

A gas pipeline approximately 85mi-long will be constructed, from the DDCV to the High Island Offshore System, which is an existing gas transmission system off the Louisiana coast.

In addition, an oil pipeline will be built and extend approximately 150mi to Freeport, Texas.