The Horn Mountain is an operating oil and associated gas field located off the coast of New Orleans in the Gulf of Mexico.

The field was initially developed and operated by BP (66.7%) in partnership with Occidental Petroleum (33.3%) in 2002.

The ownership of the field was later obtained by Plains Exploration & Production that was further acquired by Freeport-McMoRan, which sold its stake in the field to Anadarko in 2016 through the Gulf of Mexico (GOM) assets acquisition.

Further, Occidental Petroleum acquired Anadarko in August 2019 and became the sole operator of the field with 100% working interest.

Project location and discovery

The Horn Mountain development lies in 5,400ft of water, approximately 160km south-east of New Orleans in the Gulf of Mexico. The deepwater field lies in Mississippi canyon blocks 126 and 127 with a structurally complex reservoir setting.

The leases for the Horn Mountain field were acquired in 1997 and 1998. Exploration drilling began in July 1999 and the discovery was announced in August of the same year when the semi-submersible drilling rig Ocean Victory drilled to 14,600ft and encountered nearly 300ft of pay from four Miocene intervals. A side-track revealed a column of around 550ft.

Delineation drilling began immediately, taking advantage of rig availability and advanced field planning. The decision to immediately appraise the field cut months, if not years, off the total development time. Eight production wells and two injection wells were drilled in 2001 using the Ocean Victory. The wells averaged 16 days per every 10,000ft drilled. The project went from discovery to production in just under 40 months.

Drilling activities at Horn Mountain field

Drilled in the first quarter of 2017, the first development well under Anadarko, encountered the net oil pay of more than 70ft in the prolific Miocene sands, which was tied back to the Horn Mountain facility. It was brought online in the second quarter of 2017.

The second development well was drilled in the third quarter of 2017 that encountered 120ft of high-quality oil pay and was brought online in the third quarter of 2017. The third development well, drilled in the fourth quarter of 2107, encountered 42ft of high-quality oil pay. It came online in the second quarter of 2018 and is producing approximately 8,000bopd from a single zone.

The wells flowed at an average rate of 15,000 barrels of oil (bpd) and 12 million cubic feet of gas per day (MMcf) at the start of production. This eventually peaked at a rate in excess of 65,000bpd and 68 million cubic feet of gas per day in 2003 and the oil production declined to approximately 12,500bpd in 2018. The production facility can accommodate additional incremental production if new discoveries are made in the region.

Horn Mountain field development

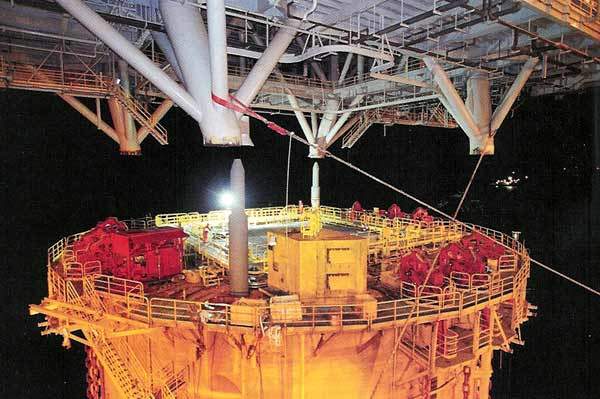

Horn Mountain was developed using a truss spar, making it one of the deepest free-floating dry tree systems in the world. The truss spar design that the field uses is only the third of its type in the industry.

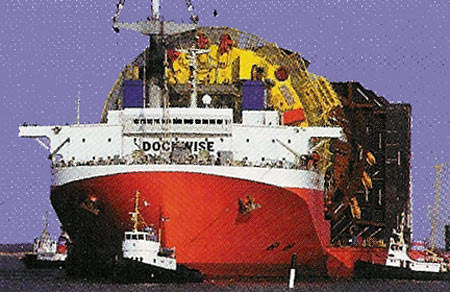

The hull structure measures 585ft in length and 106ft in diameter. It features heave plates to dampen the movement. The hull was designed by CSO Aker and built at the Mantyluoto Works yard. Meanwhile, the topsides began construction at Ingleside, Texas, by Gulf Marine Fabricators. The topsides design was carried out by Alliance Engineering. The design was strongly influenced by the ability of Heerema’s Balder installation vessel, which has a maximum lifting capability of 4,700t.

Intec Engineering was contracted for the pipeline infrastructure. The lines were laid by Allseas’ vessel Solitaire. To carry out drilling operations, the rig facilities on the vessel were supplied by Helmerich and Payne.

The spar can support 14 dry trees. The wells connect to the spar by means of a dual barrier riser system. This consists of a 9 5/8 internal riser set into a 12¾ outer riser. This was designed by ABB Vetco Gray. The large tensions from the deep waters are supported by 240ft-long by 12ft-diameter air cans.

The completed spar hull sailed from Finland in April 2002 and arrived in the Gulf in late May. The topsides production facility and quarters packages sailed from Ingleside in early June. The spar hull and topsides facilities were mated in June.

Horn Mountain field export

Oil is exported through Shell’s Odyssey pipeline system. Gas is transported throughout the 10in line to the Destin system operated by BP. The $600m project is expected to result in the ultimate recovery of an estimated 150 million barrels of oil and gas equivalent.