The Jacky oil field in the UK part of the Central North Sea is proposed to be decommissioned. Operated by British oil and gas company Ithaca Energy, the Jacky field represents the first field development completed by the company.

The first oil from the Jacky field was achieved in April 2009 and operations continued until production ceased in 2014. Ithaca handed back the Beatrice area facilities that were used for processing and export of the oil produced from the field to UK-based oil and gas exploration and production company Repsol Sinopec (previously Talisman Energy). The facilities had been leased and operated by Ithaca since 2009 until the end of its lease agreement with Repsol Sinopec in 2015.

As part of the decommissioning programme, the well abandonment has been completed at the Jacky field and the removal of the wellhead platform is scheduled to begin by the third quarter (Q3) of 2021.

Jacky oil field location and details

The Jacky oil field is located in the Inner Moray Firth area of the North Sea in block 12/21c of the UK sector within the Central North Sea. The discovery was successfully appraised by the drilling and testing of the 12/21c-6 well in May 2007.

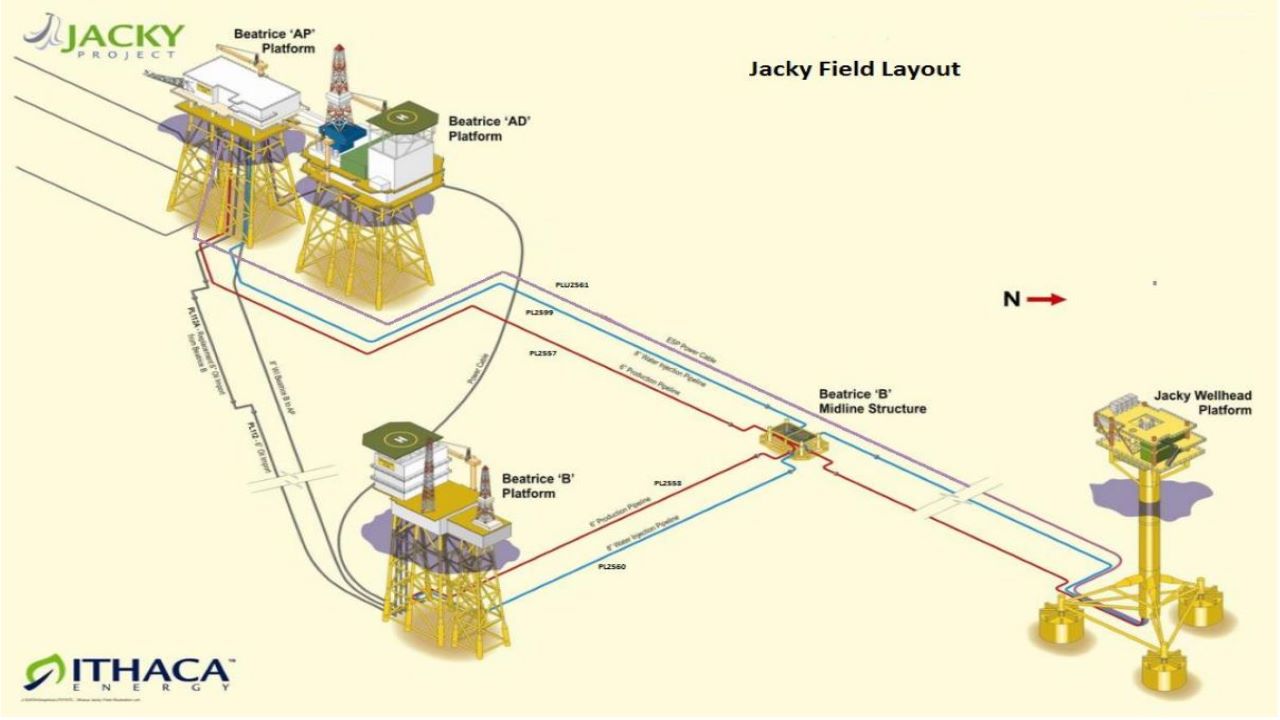

The field was tied back to the existing processing facilities in the Beatrice area during 2008-2009 when the appraisal well was re-entered and completed as a production well, 12/21c – J01.

The Jacky field development comprises a production well and a water injector well, tied into the unmanned mono-tower Jacky Wellhead Platform with a topsides production tree and production manifold in 40m water depth. The production from the platform was exported through a platform riser and subsea pipeline to the Beatrice Alpha (AP) platform approximately 10km to the south for onward export to the Ithaca-operated Nigg onshore oil terminal in the village of Nigg, Scotland.

A 12/21c – J02 water injection well with a water injection tree and header was installed with injection water sourced from the Beatrice Alpha (AP) platform via a subsea pipeline. An appraisal well (12/21c – J03) was also drilled and suspended.

Cessation of production at Jacky oil field

The production from the Jacky field was suspended due to falling production rates and equipment failures. Ithaca submitted the notification for the cessation of production in 2014 which was approved by the UK Oil & Gas Authority (OGA) in August 2014.

In June 2020, the Jacky oil field well abandonment programme was completed using the Valaris 101 jack-up drilling rig. The three-well campaign was completed within 50 days.

Jacky oil field decommissioning programme

The decommissioning works of the Jacky field installation and pipelines will involve a diving support vessel (DSV) or a heavy lift vessel (HLV).

The Jacky production wells will be plugged and abandoned using a jack-up drilling rig. Ithaca will submit a PON5, marine licence and portal environmental tracking system (PETS) to the Department for Business, Energy and Industrial Strategy (BEIS) for approval to abandon the wells. The topsides will be separated from the monopile jacket and placed on a barge for transportation to an onshore location where it will be reused or recycled.

The removal of the monopile jacket and suction piles will be executed using a reverse installation procedure. The project will also involve disconnecting the tie-in spools and completely removing the structure in a single lift by a construction support vessel (CSV). The structure will be transported onshore for reuse or recycling.

The 6in production pipeline, including the spur from the midline tee (MLT) structure to the Beatrice Bravo gas/liquids production platform, the 8in water injection pipeline including the spur from MLT to Beatrice Bravo and the 6in power cable will be disconnected and left in situ with the ends re-buried.

The waste material generated during the decommissioning process, including steel and other recyclable metals, is planned to be transported onshore to licensed waste contractors. Once the decommissioning is completed, a survey will be conducted at the site to recover/recycle seabed debris.

Contractors involved

Ensco Offshore UK was awarded a contract to provide a mobile drilling unit for the plug and abandonment operations as part of the Jacky field decommissioning project.

In December 2019, Dutch company Heerema Marine Contractors was selected for the works involving offshore removal and onshore disposal of the Jacky wellhead platform.

In 2015, Petrex Developments, a sub-sea engineering and project management consultancy based in the UK, conducted engineering studies to define decommissioning methodologies, schedules and costs for the project. The scope of the study also included front-end engineering design (FEED) activities and pipeline conditioning.