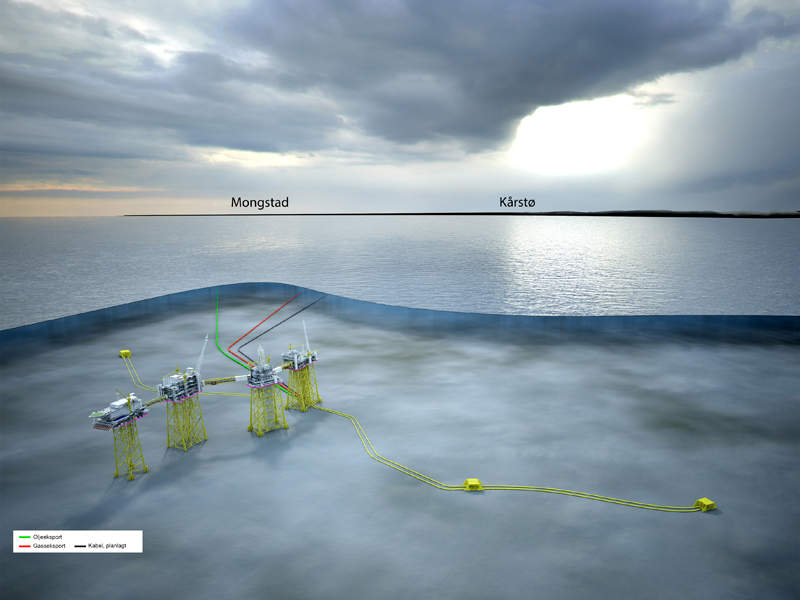

The Johan Sverdrup export pipeline project will involve the laying of underwater pipelines in order to transport the oil and gas produced by the Johan Sverdrup offshore oilfield, which is located in the North Sea, Norway.

It is expected to be one of the biggest oil pipelines on the Norwegian continental shelf.

The Johan Sverdrup offshore field is being jointly developed by its operator Equinor (formerly Statoil, 40.03%) along with Lundin Norway (22.6%), Petoro (17.36%), Aker BP (11.57%) and Total subsidiary Maersk Oil (8.44%).

The pipeline will transport approximately six million cubic meters of gas per day to the Kårstø gas terminal, while the oil export pipeline will transport 660,000 barrels of oil per day to the Mongstad terminal.

A route study for the laying of the subsea pipeline for the Johan Sverdrup oilfield was conducted in 2015.

The Nkr2.5bn ($287.2m) Johan Sverdrup export pipeline project is expected to be completed by 2019.

Johan Sverdrup export pipeline details

The Johan Sverdrup oil pipeline will be 283km-long and have a diameter of 36in, while the gas export pipeline will be 156km-long and feature a diameter of 18in.

A total of approximately 440km of pipelines are anticipated to be laid as part of the initiative.

The project will involve the use of 36,000 pipes made with 230,000t of steel.

The pipelines will be coated with anti-corrosive chemicals and are expected to weigh approximately 360,000t following the coating process.

Saipem’s Castorone pipe-laying vessel will be used to lay the pipeline under the sea.

The Castorone vessel is 330m-long and has a capacity to accommodate 702 people.

The pipeline’s deepest installation point is currently slated to be 537m below the sea.

DeepOcean’s construction vessel Edda Freya will be responsible for the remote hyperbaric tie-in of the oil export pipeline to the Johan Sverdrup riser platform, which is scheduled to be carried out between 2018 and 2019.

The pipeline’s receiving facilities are to be built on the Mongstad complex and will be tied-in to the existing utilities and control systems.

Contractors involved

Mitsui & Co Norway was contracted to provide pipeline fabrication services for the project, while the pipe-laying contract was awarded to Saipem.

The pipes will be produced by Nippon Steel & Sumitomo Metal (NSSMC).

Wasco Coatings Malaysia was contracted to provide external anti-corrosion treatment, internal flow coating and concrete weight coating for the pipelines.

The NorSea Group AS (NSG) is providing intermediate storage services for the project’s pipelines, while DeepOcean was awarded the engineering, procurement, construction and installation (EPCI) contract to tie-in the oil export pipeline.

Aker Solutions was awarded a Nkr350m ($43m) contract to construct pipeline receiving facilities, as well as perform modifications and tie-ins at the Mongstad terminal.

Fugro GEOS provided construction planning services, while IES-Velosi, a unit of testing and inspection service provider Applus+, was contracted to provide inspection services.

Johan Sverdrup offshore field background

The Johan Sverdrup oilfield is one of the biggest oilfields to be discovered in 2010.

It is located in the Utsira High region of the North Sea, approximately 140km from the Stavanger coast, Norway.

The total recoverable resources of the field are estimated to be between 2.1 and 3.1 billion barrels of oil equivalent.

The field is being developed in phases, with the first phase expected to start production by the end of 2019.

It is expected to have an estimated production capacity of 440,000 barrels of oil equivalent per day (boed).

The second phase is expected to begin production by 2022 and will have an estimated production capacity of 660,000boed.