The Jotun field is located on the Utsira High, between the Balder and Heimdal fields, approximately 200km west of Stavanger, Norway. Its average water depth is 126m. Geologically, Jotun consists of the Elli, Elli South and Tau West structures.

ExxonMobil is the project’s operator with an equity share of 45%. Dana Petroleum holds 45%, followed by Det norske with 7% and Petoro with 3%.

Jotun reservoir

The 4km x 5km Jotun reservoir lies in a Paleocene basin. The oil / water contact was located 2,091m below the seabed. The oil column thickness in the exploration wells ranges from 18m-46m.

Recoverable reserves are estimated at approximately 200 million barrels of oil (32 million cubic metres) and 1.8 billion cubic metres of gas.

Reservoir drilling

Reservoir development plans call for 11 horizontal oil producers, six water injectors and two wells producing injection water.

Water produced from the oil processing is also reinjected into the reservoir to provide aquifer support during production.

Water-based drilling mud is used whenever possible, while oil-based drilling fluid is recirculated and reinjected. The wells have a measured depth of up to 7,000m. There are plans for two exploratory wells to be drilled.

Development and production

Jotun is developed by the floating production and storage unit Jotun A and the wellhead / drilling platform Jotun B. Production from the field started in 1999. The field reported an average annual production rate of 6,800bopd for 2008 compared with 13,000 in 2005.

The decline in the field’s production resulted in spare production capacity. To make use of this spare capacity, the Balder field was linked to Jotun by a gas pipeline in 2003. A pipeline connecting Ringhorne and Jotun was installed in 2004.

The pipeline from Jotun to the Gassled statpipe system leaked causing temporary stoppage of gas exports from the project in the second half of 2004. However, exports were resumed in November 2004.

Production vessel: Jotun A

The Jotun A production storage vessel is 233m-long and 42m-wide. The topsides construction was carried out at the Kvaerner Rosenberg yard at Stavanger, while the hull engineering and construction was carried out by Kvaerner Masa Yards, in Finland. The production vessel hull has double sides and bottom.

The topsides contain processing, living quarters, power generation, utility systems, safety and emergency systems, support communication, control, instrumentation and electrical systems. The flare is placed aft.

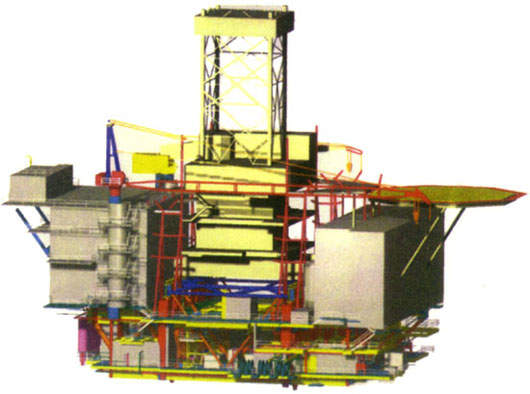

Topsides: Jotun B

The wellhead platform consists of an integrated deck with utilities, wellhead systems, a helideck, support systems and complete drilling facilities with derrick and mud facilities.

Herema Tonsberg, the main contractor in a consortium with ABB Offshore Technology, carried out deck construction and WHP integration.

The platform deck engineering and installation of electrical and instrumentation systems, along with the offshore hook-up, were carried out by ABB in Oslo.

The drilling facility was engineered by Bentec in Oslo, while the drilling module was fabricated by Kvaerner at Teesside, UK. The living quarters, with accomodation for 90 people, were built by Emtunga in Sweden. The topsides total weight is 7,800t.

Jacket, risers and flowlines

The sub-structure consists of a four-legged steel jacket with a piled foundation. The weight of the jacket is 6,300t. The 24-well slot jacket was built by Aker Maritime at Oslo / Verdal.

The flowlines and risers transmit all produced fluids from the oil and water source wells running from the wellhead platform to the FPSO; and all the necessary water injection and gaslift from the FPSO.

Each riser is made of an unbonded flexible pipe with a single-layer nylon pressure sheath. These are configured in a ‘lazy-S’ arrangement, which uses two buoyancy arches, 60m above the seabed. Risers are reinforced to avoid overload at the turret entrance below the vessel.

Processing

The production system contains the necessary facilities for inlet separation, crude-oil stabilisation and dewatering, gas dehydration, hydrocarbon dewpoint conditioning, sales and gas-lift compression, product metering, and chemical and water injection systems.

Jotun’s system has a design rate of approximately 100,000bopd and a storage capacity of 580,000 barrels.

Turret

The production vessel weathervanes around the bow turret, which has a swivel system for transferring well-stream fluid / gas, injection water and gas, signals and power between the turret and the vessel.

The turret is designed to accommodate seven risers, an integrated umbilical and a subsea isolation valve umbilical. This is anchored to the seabed using 12 mooring lines.

The engineering and project management of the turret was carried out by Bluewater, in Holland.

Staff accommodation

The living quarters, located in front of the turret, were engineered and constructed by Consafe, in Aberdeen. They have accomodation for 60 people, as well as containing offices and recreation rooms.