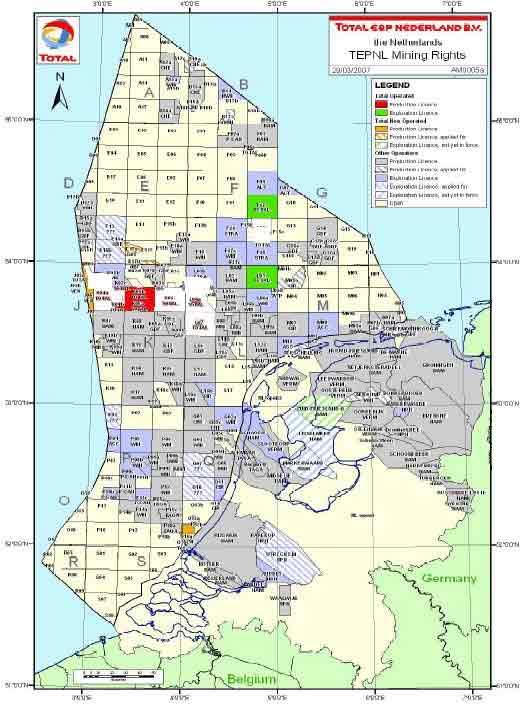

The K5F field is located in block K5 in the Dutch sector of the North Sea, approximately 110km northwest of Den Helder. It is operated by Total E&P Nederland BV of behalf of its partners Energie Beheer Nederland BV, Goal Petroleum (Netherlands) B, Dyas BV and Lundin Netherlands BV.

The field began production in September 2008, initially at the rate of 45Mmscf/day and ramping up to 90 Mmscf/day over the subsequent few months. The total budget for the project is estimated at about $.

K5F subsea installations

The project includes a three-well combined template/manifold installed in 40m of water. The initial installation encompasses two template/manifold-mounted trees with the option for two more trees in the future, one of which would be a satellite tree.

The jack-up drilling rig Ensco 72, used to drill these wells, was also used to install the two Christmas trees.

The produced gas is exported through a 10km-long, 8in-diameter subsea pipeline connected to the existing K6N satellite platform. The gas treatment facility on the K6N satellite platform has been modified in order to process the K5F gas. From there flow is exported via the K6 central complex for delivery to shore along the NoordGas Transport pipeline under contract to Gasunie for supply to the local gas network.

Subsea 7 received a contract valued in excess of $70m for engineering, procurement, construction and installation of the 8in-diameter flowline and umbilical systems, together with the associated tie-in and pull-in operations. The contract also included the engineering, procurement, fabrication and installation of the subsea protective structure complete with the pipeline end manifold, integrated umbilical distribution equipment and associated activities.

The massive 160t subsea cover was subcontracted to engineering contractor, Isleburn where it was built at the company’s Nigg facility in a contract worth £800,000. The subsea cover was loaded onto a barge by a 500t crane at Nigg, for subsequent transfer to DSV Toisa Polaris. It was transported 400 miles to the K5F field in 48 hours.

All-electric christmas tree

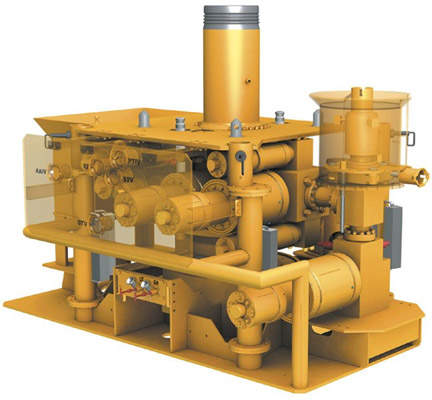

The keynote of the K5F project is that it marks the first worldwide implementation of an all-electrical Christmas tree as opposed to the more common arrangement where the downhole valves are operated hydraulically. Cameron was awarded the contract by Total E&P for the supply of this all-electric subsea production system.

The system, powered by direct current, is designed to dramatically improve reliability, availability and maintainability. The system has no batteries or accumulators and much of the conventional electro-hydraulic equipment has been simplified or eliminated.

The operation and control and operation of the subsea installation is from the K6 central complex, around 17km away. In addition, the surface platform contains tanks and pumps for the mono ethylene glycol to prohibit the formation of hydrates in the pipeline.

The control system is configured for expansion to four wells.

By eliminating hydraulics for power and signals, the control-system commands can be sent in rapid succession, thus avoiding the lag time required for accumulator charging. High-speed communication provides near-instantaneous communication with equipment as well as feedback on subsea conditions.

The all-electric system eliminates the potential for hydraulic leaks and the issue of hydraulic-fluid disposal. This system includes an electric subsea control module, a power-regulation and communications module, electrically actuated chemical-injection valves, annulus and production gate valves, and an electrically actuated choke.