The Kikeh field is located 120km north-west of the island of Labuan in Block K, offshore Sabah, East Malaysia, in water depths of approximately 1,330m. Murphy Sabah Oil Company operates Kikeh on behalf of its partner Petronas Carigali.

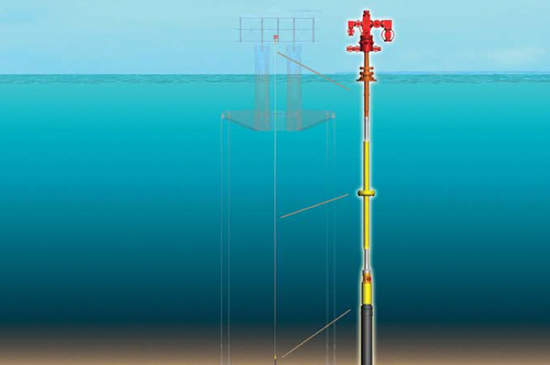

The Kikeh oil and gas field, the first deepwater development in Malaysia, was developed with floating production storage and offloading (FPSO) vessel. The FPSO is fed by wells drilled from a Spar dry tree unit (DTU).

Kikeh has a recoverable reserve base in excess of 400 to 700 million barrels of oil. The first oil from the field was achieved in August 2007 with a production ramp-up of 120,000bpd. Project capital expenditures were projected at approximately $1.4bn.

In early 2006, Petronas awarded Murphy a deepwater license for block P and an extension to the exploration term of a portion of block K. Blocks K and P extend across an area of approximately 4,111km² and 4,246km², respectively, and lie 3,000ft-9,000ft deep in the water. Block P lies on-trend 110km to the northeast of block K.

Murphy carried out a large drilling programme to appraise the limits of the oil trend and the adjacent fault blocks. Drilled in 4,217ft deep water in Block K in April 2004, the Kikeh 7 appraisal well confirmed the down-dip limits of the field.

Kikeh field development

Kikeh field contains truss spar floating production platform or DTU, measuring 142m-long and 32m in diameter. The Spar incorporated a tender assisted drilling rig to drill and complete the Kikeh wells. The spur platform features topside facilities, hull, mooring system, and riser or wellhead systems. It has a 25-slot well bay for dry tree wellheads.

Murphy awarded the contract for the engineering, procurement, construction, installation and commissioning of the unit to Technip Marine (Malaysia). Construction and completion work was carried out by Malaysia Shipyard & Engineering’s facility in Pasir Gudang, Johor, Malaysia.

FMC supplied ten surface/dry trees with a pressure of 5,000psi, as well as ten OD production risers and joints. It also supplied a surface BOP drilling riser system.

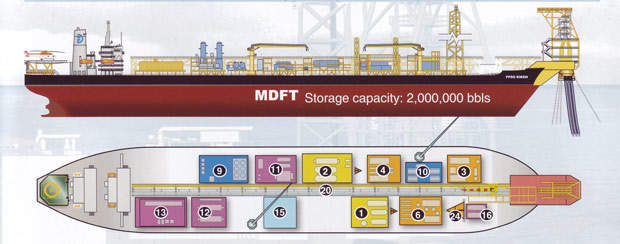

Floating production storage and offloading (FPSO) unit

The FPSO Kikeh is located in 1,350m of water. It is owned by MDFT Labaun and operated by MDPX Sdn Bhd, two joint ventures (JV) between SBM and Misc Berhad. The converted tanker was built in 1974. The FPSO has an overall length of 337m, a breadth of 54.6m and a deadweight of 273,000t. It has a storage capacity of two million barrels and is designed to remain in the field for 20 years.

The FPSO can accommodate oil production at a rate of 120,000bpd and water injection at 260,000bpd water. It can compress gas at 135 million cubic feet a day.

The bow contains an external turret that can accommodate up to 17 flexible risers ranging from 8in to 10in diameters. There will be nine risers to start with, four in the future, three umbilicals and one spare.

The swivel houses a 12in subsea production line, a 14in high-pressure production line, a 10in oil import line(future), a 10in low-pressure production line, a 16in water injection line, an 8in test/pigging line, a multi-path double-drum, a high-voltage power electric line, a low-voltage/signal line and an 8in gas export line.

The metering system is based on three turbo meter runs with a prover loop. The FPSO has four 4,500m³/hr carbo pumps.

Power is provided by two 12MW steam generators and two 1,800kW diesels. There are two 87t/hr boilers.

Contractors involved

Technip was awarded the contract for the engineering, design, supply and installation of the Kikeh Area Development subsea pipeline and riser system.

The project includes the design, supply and installation of flexible flowlines and risers, holdback anchors, the installation of control umbilicals and manifolds, tie-in of the subsea wellheads, hook-up of the risers to the Kikeh floating production and offloading system and the pre-commissioning of the system.

The offshore installation utilised Technip’s vessel Venturer and Subsea 7’s vessel Rockwater 2.

Aker Solutions supplied a subsea production system for the project while Menck installed mud mats and mooring piles.

Reach Integrated is responsible to perform preventive and corrective maintenance activities for the Kikeh FPSO unit.