Kizomba Satellites Phase II involves the development of the Kakocha, Bavuca and Mondo South satellite fields located within Block 15, approximately 150km off the coast of Angola, at a water depth of approximately 1,350m.

Production from the Mondo South field began in April 2015 while the other two satellite fields are expected to start producing later in the year. Peak production from the project is estimated to reach 70,000 barrels of oil a day.

The project aims at recovering approximately 190 million barrels of oil from the three satellite fields and increase the overall daily production capacity at Block 15 to 350,000 barrels.

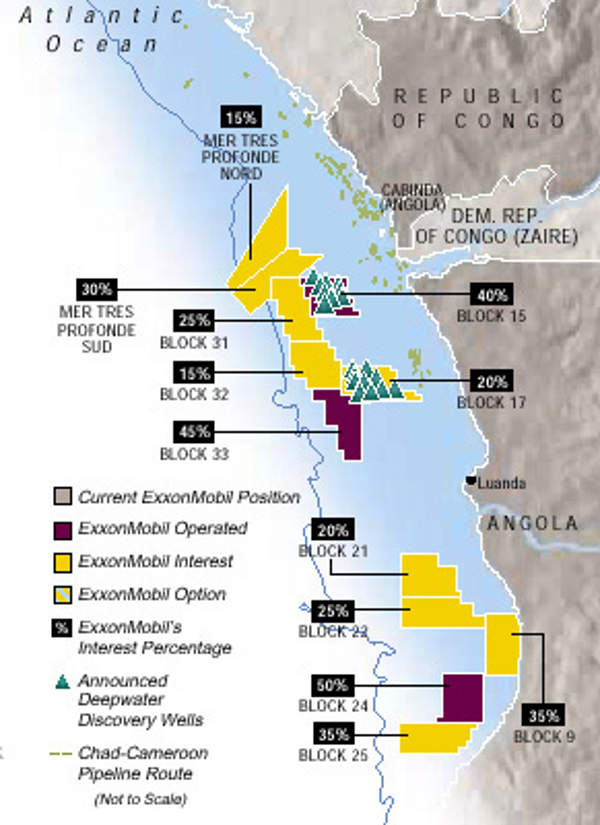

Operator Esso Angola holds a 40% interest in Block 15 whereas Sonangol is the concessionaire. Other partners in the project and block include BP Exploration Angola (26.67%), Eni Exploration Angola (20%) and Statoil Angola Block 15 (13.33%).

The overall investment in the project is estimated to be $2.4bn. Approximately $740m has been invested to bring the project to the first production.

Phase II development details of Kizomba satellite fields

Subsea facilities at the Mondo South field are tied back to the existing Mondo floating, production, storage and offloading (FPSO) vessel, while the Kakocha and Bavuca fields are being developed as tiebacks to the existing Kizomba B FPSO.

The project involves the drilling of 24 production wells, modifications to the topsides of the existing two FPSOs and installation of subsea flowlines and equipment.

The Kizomba B FPSO, built with an investment of approximately $3bn, has a production capacity of 250,000bpd and a storage capacity of 2.2 million barrels, whereas the Mondo FPSO has a designed production capacity of 10,000bpd and a storage capacity of 1.6 million barrels.

Angola offshore Block 15 details

Block 15, which covers an area of approximately 4,144km² is estimated to hold oil reserves amounting to five billion barrels. As of April 2015, the block is estimated to have produced more than 1.8 billion barrels of oil.

The deepwater block produced the first oil through the Xikomba field in 2003, followed by Kizomba A in 2004, Kizomba B in 2005 and Kizomba C in 2008. A gas gathering project at the block was completed in 2011, enabling the transportation of associated gas from the Kizomba A and B FPSOs to the Angola LNG facility in Soyo.

Production from Kizomba Satellites Phase 1 started in July 2012. It involved the development of the Mavacola and Clochas fields, which are estimated to hold 250 million barrels of oil. The $1.5bn project involved the development of 18 wells, which are tied back to the existing Kizomba A and B FPSOs.

Contractors involved with Kizomba Satellites Phase II

The pre-front end engineering and design (pre-FEED) and FEED studies for the project were performed by Amec.

The consortium of Saipem, Petromar (Angola) and Saipem (Portugal) Maritime Trade is involved in the engineering, procurement, fabrication and installation of production and water injection pipelines and flowlines measuring approximately 60km, rigid jumpers, and other related subsea structures.

Paragon Angola is performing the engineering and procurement for the project’s topsides modifications.

Oceaneering International supplied approximately 43km of electro-hydraulic steel tube control umbilicals for the project. It further subcontracted FES International to supply two automatic diverless bend stiffener connector (DBSC) units to connect the umbilical bend stiffeners (UBS) to the FPSOs.

Hydrasun was subcontracted by MSCM to supply 55 hydraulic flying leads (HFLs) for the project. Seatrucks Group was contracted to supply its Jascon 30 DP3 pipelay accommodation vessel for the project.

The subsea crossing supports and structures integrating low-friction, ultra-high-molecular-weight (UHMV) polyethylene and Monel alloy fixings for the safe installation of the pipelines were supplied by Subsea Protection Systems (SPS).