South Marlim was discovered in November 1987 by the wildcat well 4-RJS-382.

The field is located 110km (68mi) off the northern shore of the Rio de Janeiro state. Its water depth varies from 720m in the north to 2,600m in the south of the field.

Approximately 80% of the field area is in a water depth greater than 1,200m.

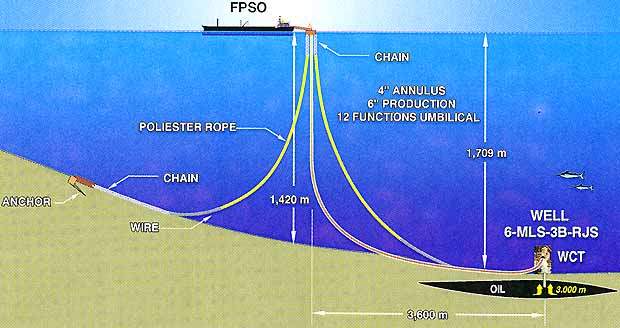

The deepest well is the South Marlim 3B (MLS 3B), which set a new world water depth record of 1,709m (5,607ft), breaking the 1,615m record that was set on Shell’s Mensa field a month earlier.

Mensa is a natural gas-only well, whereas MLS 3B is both oil and associated gas.

The MLS 3B well was drilled from the dynamically positioned drillship Noble Leo Segerius (formerly Neddrill 1) to a total depth of 3,167m (10,390ft).

It discovered 93.5m (307ft) net pay of gas and oil.

The well came onstream at an initial rate of 4,500 barrels per day (bpd) without gas lift.

This will gradually be increased to 7,500bpd of oil. The field started producing in April 1994 with well 3-MRL-4-RJS (now linked to the P-20 platform).

Field development

Petrobras’ initial development plans called for the installation of two semisubmersible producing units with a processing capacity of 150,000bpd.

However, the MLS 3B drill stem tests suggested that the reservoir could contain 1.2 billion barrels of oil in-place alone.

The company later planned the development in different modules such as 1, 2, 3 and 4. Petrobras opted for a two-phase development plan under Module 1.

Phase one is based upon the Marlim Sul pre-pilot early production system, consisting of the MLS 3B subsea completion, as well as the possibility of including a second satellite well.

This well produces into an FPSO moored in 1,420m (4,659ft) of water, lying a distance of 3,600m from the wellhead.

The FPSO receives and processes the oil and gas, provides gas-lift facilities and stores the oil for offloading operations to a shuttle tanker.

Phase two exploits the remaining field area and depends on additional well information, seismic and geological interpretation, as well as technological developments in drilling, completion and equipment.

FPSO

Petrobras selected the converted trading tanker FPSO II for use in South Marlim.

FPSO II originally started life as the 127,000dwt tanker Mariblanca. This was converted in 1982 for service in the Cadlao field in the Philippines.

It was subsequently refurbished and modified for the Linapacan field, also situated in the Philippines.

Following the Marlim Sul contract, FPSO II was taken to the Sembawang shipyard in Singapore in November 1996 for upgrading.

The well 6-MLS-3B-RJS started production linking to the FPSO-II in the Module 3 area in August 1997. The vessel was moored in a water depth of 1,430m.

Production from the unit was ceased in 1998. Eventually, FPSO II was sent to into Module-2 region, with start of production from well 3-MLS-2RJS in 1999 and followed by production from well 4-RJS-442 in December 2000.

Production from vessel P-40 started in December 2001 with the start of production from 7-MLS-10HPB-RJS well in Module 1.

Under this module, wells directly produce to P-40 platform at a depth of 1,080m.

Upon completion of processing on platform P-40, the oil produced is sent to FPSO P-38, which comprises 21 wells, including 13 production wells and eight injectors and is hooked up at depth of 1,009m.

The oil stored is sent to onshore terminals, while gas is first compressed on P-40 and sent to the Namorado platform in the Namorado field.

Due to the increased production ability of P-40 wells with the capacity to inject more, a complementary development project was brought onstream for Module 1.

The development project involved the FPSO Marlim Sul platform. This platform was hooked next to P-40 at a water depth of 1,180m.

The oil stored in the Marlim Sul platform is systematically transferred to alleviator vessels for further transferring to onshore terminals.

The gas produced is compressed and sent to P-40. The Marlim Sul platform has 11 operating wells, including six production and five injectors.

Under the production development project for the field, 21 wells have been planned to be tied to platform P-56. The 21 wells, including ten producing wells and 11 injectors, will be interconnected.

The platform will have the capacity to produce 100,000bpd, can compress 6 million cubic metres per day and can inject up to 45,000m³ per day of water.

The oil will be transferred to P-38 and gas will be exported to P-51. The oil from the platform is expected to come onstream in 2011.

Module 1 has 37 wells consisting of 22 producers and 15 injectors. Out of 37 operating wells, one production well along with one injector well is linked to P-37 and similarly, one producing and one injector well are interlinked to P-26.

These platforms come under the Marlim Field.

Development modules 2, 3 and 4

Module 2 was in implementation phase as of January 2009. This phase is about to start its first year of operations. Production unit Petrobras-51 (P51) is to be installed under this module at a depth of 1,255m.

The unit will have a capacity of 180,000bpd and is expected to have ten producing wells along with nine injectors.

The oil inflows via pipelines joining to platforms P-38, FPSO-MLS and Autonomous Repumping Platform-1 (PRA-1), fixed platform, are planned to be installed.

Mooring

FPSO II is moored on the field by a 19m-diameter single buoy storage (SBS) system, which is permanently connected at the stern by a rigid yoke.

The anchoring arrangement consists of six equally spaced composite catenary anchor legs consisting of wire rope, studlink chain, polyester rope and studlink connected to chain stoppers on the fixed buoy section of the SBS.

The FPSO weathervane capacity is achieved by a three race roller-bearing arrangement, connected to the rotating SBS.

Subsea tree

In the first run, the wet christmas tree was run with flowlines connected to it using the layaway method.

The running of the tree was performed by the DP drillship Noble Roger Eason following its upgrade to enable it to operate at a depth of 1,800m.

The lines linking the subsea tree with the FPSO, including the 4in annulus flowline, 6in production flowline and 12-function 4,800m-long (15,748ft) umbilical, with a nominal diameter of 120mm (4.76in). These were laid by the Sunrise 2000.

Export

Crude oil transfer is from the flexible risers through the SBS manifold, the toroidal swivels, the hard piping on the SBS yoke and the pipe swivels across the yoke to tanker articulation, and hard piping to the process deck.

Marlim Sul contracts

The EPC contract for P-56 production platform was given to the Femtosecond Technology Project consortium of Technip and Keppel FELS in December 2007.

The platform is expected to be delivered in the fourth quarter of 2010.

Aker Kvaerner is the designer of the hull of P-56.

FMC Technologies executed an EPC contract for the field development during 1996-2002.

The contract services were provided for subsea trees, pipelines end terminations, 18 vertical connection modules and system integration testing, offshore installation support and technical assistance were provided.