Marlim is located in the north-eastern part of Campos Basin roughly 110km offshore Rio de Janeiro, in water depths ranging from 650m to 1,050m.

It has some 102 production wells and 50 injection wells. Over 80km of rigid pipelines and 400km of flexible lines have been laid on the field.

The field produces around 390,000 barrels of oil per day (bopd) and 252,000 barrels per day (bpd) of water. Around 705,000 barrels of water are injected into the field a day.

The refinery has reported an average production of 353,027bpd for 2007.

Discovery

Marlim was discovered by well 1-RJS-219-A in February 1985. The 75m column was predominantly unconsolidated sandstone, with a permeability as high as two darcies.

The discovery also showed high-gravity oil (17°-21° degree API). At the time of discovery, the Marlim reservoir had an oil-in-place volume of about 9 billion barrels and an expected 1.7 billion barrels of oil in total reserves.

Pilot well

By 1990, the field area ranged between 650m and 1,050m, and covered 137km².

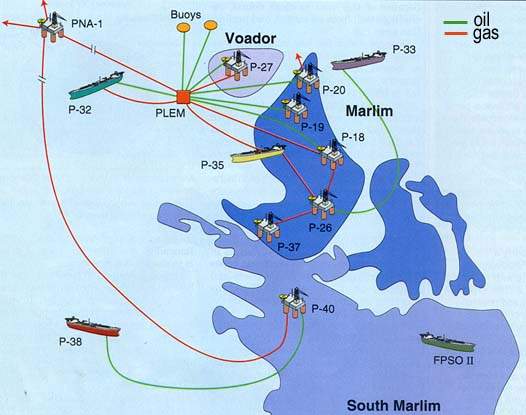

A pilot system was used for exporting through two monobouys to the shuttle tankers, which consisted of a semi-submersible unit with ten subsea production wells.

First development phase

The first phase was divided into two modules. Module 1 was developed using the new-built semi-submersible P-18 and a former Petrobras VLCC, Cairu, which was converted into P-32/

Module 2 comprised 12 subsea production wells and seven subsea injection wells, and was developed using the converted semi-submersible P-19.

Second development phase

The second phase began in June 1995 and saw the development of the southern and central areas (modules 3, 4 and 5).

Module 3

Module 3 development was based on 15 subsea production wells and ten injection wells, delivering at a rate of 100,000bopd and 3 million square metres of gas per day, tied back to the converted semi-submersible P-26.

Oil was then transferred to the existing FPSO P-33, installed as part of module 2.

Built in Russia in 1984 under the name Illiad, the rig was transformed into the P26 floating production system at the Astileros shipyard in Cadiz, Spain.

Conversion works took nearly two years.

Expansion and reinforcement of the original structures consumed over 5,000t of steel and over 300,000m of electric cable.

Module 4

The module 4 development is based on the ore-oil VLCC, José Bonifácio, which was converted into the P-35 FPSO by Hyundai Heavy Industries in Korea.

With a length of 337m, the P35 has a capacity to produce 100,000bopd and 3 million square metres of gas per day from 27 wells (19 subsea production wells and eight injection wells) located in two subsea manifolds at water depths of 7,870m and 820m respectively.

It also has a storage capacity for two million barrels of oil.

The P-35 came onstream in May 1999.

Module 5

Module 5 required a larger FPU to develop a new reservoir that was found below the Marlim reservoir in the adjacent area, RJS-396.

Petrobras converted another vessel, Friendship, into the FPSO P-37. This has a process capability of 150,000bopd.

It will be fed by four subsea manifolds, 20 production wells and 15 subsea injection wells.

P-37 was converted in Singapore and arrived in mid-1999. It came onstream in December 1999.

A second P-47 FSO plant, with a storage capacity of 1.65 million barrels of oil and the capacity to manage around 150,000 barrels per day, was developed to enhance the capacity of oil treatment of the field in 2005.

The company had earlier planned that the field development would comprise 135 subsea wells and 20 water injection wells linked to nine FPUs.

However, by 2008 the plant had eight FPUs with 129 subsea wells, including 86 production and 43 water injections, five subsea manifolds and two FPSOs.

The field development was completed in 2002.

Contract

FMC Technologies secured a $90m contract to provide a subsea separation system for the project field in August 2009.

The subsea separation module will segregate heavy oil, gas, sand and water at a water depth of around 2,950ft.

The deliveries are expected to start in 2011.

Investment

The field represents a total investment of $5bn over a 15-year period.