The Marsa liquefied natural gas (LNG) bunkering project will be the inaugural LNG bunkering hub in the Middle East.

The project is being developed by TotalEnergies (80%) and the government of Oman-owned OQ Alternative Energy (20%) through a joint venture called Marsa Liquefied Natural Gas (Marsa).

The LNG facility will be constructed on reclaimed land safeguarded by a robust embankment and leased from the Sohar Industrial Port Company (SIPC). The LNG plant is designed for a 25-year operational lifespan.

The production of LNG is anticipated to commence in the first quarter of 2028, with the primary objective of catering to the marine fuel market (LNG bunkering) in the Gulf region. Surplus LNG not utilised as bunker fuel will be off-taken by TotalEnergies and OQ Alternative Energy.

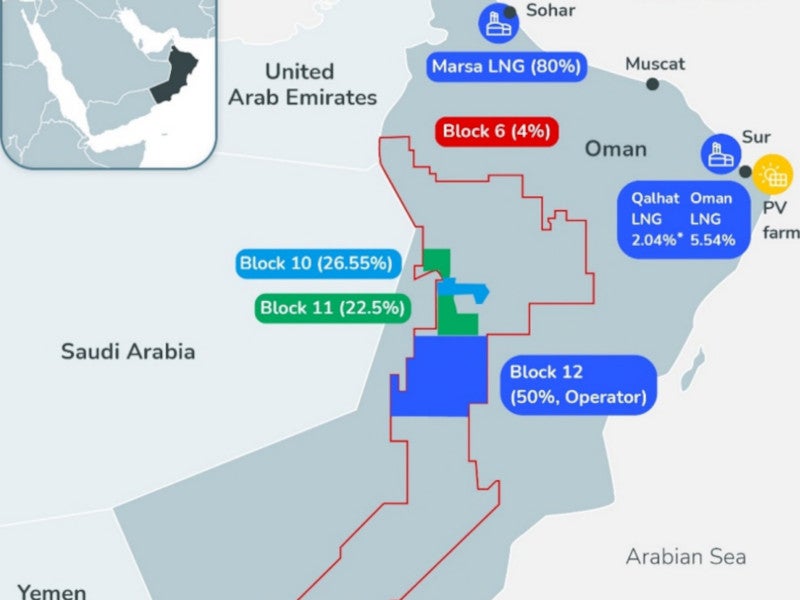

Project location

The project is located in the Sohar Industrial Port, within the Sohar Port South development area, which lies in the Wilaya (administrative division) of Liwa, in the Governorate of North Al Batinah, Oman.

Marsa LNG bunkering project details

The LNG bunkering project will feature an onshore plant, designed to process high-quality gas into LNG, with a focus on fuelling marine vessels. It will also be equipped with loading facilities for LNG carrier vessels at Sohar port.

The Marsa LNG Bunkering project will comprise a 1Mtpa capacity LNG liquefaction plant, a 165,000m³ LNG storage tank, and ancillary equipment.

An existing pipeline corridor within the port will be utilised, extending to the tank farm fence approximately 100m away. It will include 10m of buried pipeline, with the remainder elevated on an existing or upgraded pipe rack.

The LNG export Jetty’s topside will feature a jetty subsea foundation and access road, constructed and provided by SIPC, which falls outside the project’s remit. The topside infrastructure necessary for loading will encompass a pipe rack, process manifolds, LNG loading arms, safety features and a jetty control station.

Power supply details

A dedicated 300MWp photovoltaic (PV) solar plant will be established to meet the annual power needs of the LNG plant. It will enable a substantial reduction in greenhouse gas emissions. The project will be powered exclusively by solar energy, positioning it as one of the most environmentally friendly LNG plants globally.

The electrical transmission line will consist of a buried electrical cable stretching approximately 3.5km. It will link the LNG substation to the existing substation operated by the Oman Electricity Transmission Company (OETC) within Sohar Port.

The project will have an impressive greenhouse gas (GHG) intensity below 3kg CO₂ e/boe (barrel of oil equivalent), compared to the average emission intensity of LNG plants – approximately 35kg CO₂e/boe.

LNG supply details

An LNG supply of 150,000 cubic feet per day for the project will be sourced from the Mabrouk North-East field on onshore Block 10, Oman in which Marsa has a 33.19% interest.

Production in Block 10 commenced in January 2023 and reached its plateau in April 2024. The final investment decision enabled Marsa LNG to extend its rights in Block 10 until 2050.

Export pipeline

The condensate export pipeline, an integral part of the Marsa LNG bunkering project, will be a short pipeline of 1km or less, designed to transport condensate to ADVARIO’s tank farm (formerly the Oil Taking Terminal). The condensate will be stored for potential future utilisation by OQ refineries and petroleum industries within Sohar Port.

Construction phases

Phase one will involve construction, pre-commissioning, commissioning, civil works, building construction, installation of temporary facilities and mechanical/electrical tasks.

Phase two will involve the LNG plant’s startup, operations and regular maintenance of the project site facilities and associated infrastructure.

Phase three will involve the decommissioning at the end of the planned operational period. It will include a review of the project facilities and associated infrastructure for potential extension or decommissioning. The decommissioning process will involve the removal or repurposing, recycling, or disposal of surface structures, as well as site reinstatement and restoration.

Offtake agreement

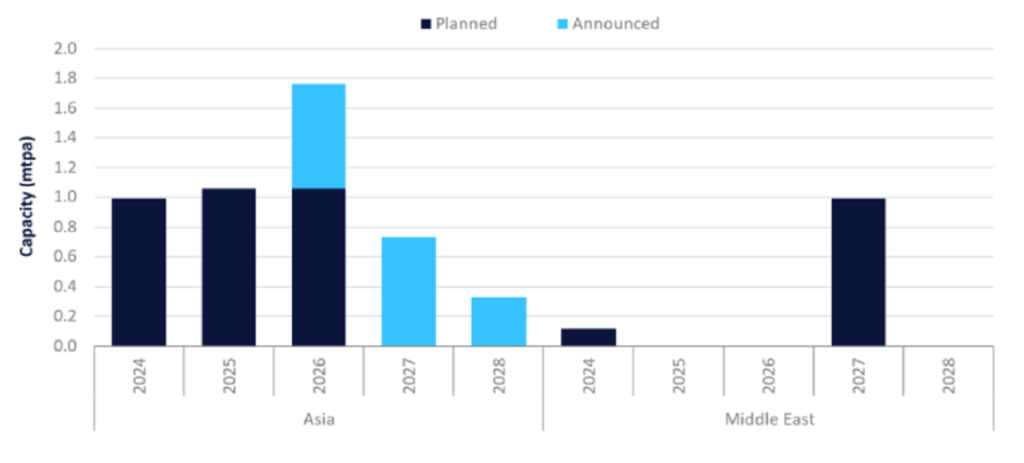

TotalEnergies entered a sale and purchase agreement with Oman LNG to acquire 0.8 million tonnes per annum (Mtpa) of LNG for ten years starting from 2025.

Contractors involved

Engineering and technology company, Technip Energies was awarded the engineering, procurement and construction (EPC) contract of the natural gas liquefaction train.

SIPC will be responsible for the substructure maintenance and mooring operations of the export jetty.

CB&I, a wholly-owned unrestricted subsidiary of McDermott, was awarded an EPC contract in May 2024 to supply a full containment concrete LNG storage tank for the project.