The Fulla oil and gas field is located in the Yggdrasil area (previously NOAKA – North of Alvheim (NOA), Krafla, Askja) at a water depth of 110m, between Alvheim and Oseberg on the Norwegian Continental Shelf (NCS).

The partners in the Fulla field include Aker BP (40%, operator), Equinor (47.7%) and PGNiG Upstream Norway (12.3%).

Equinor and Aker BP reached an agreement for the joint development of the Fulla, Munin (previously Krafla) and Hugin (previously NOA) fields as part of the Yggdrasil project in June 2020.

The plan for the development and operation of the Yggdrasil project was submitted in December 2022 and approved by the Ministry of Petroleum and Energy in June 2023.

The production from the field is expected to commence in 2027.

Yggdrasil licence area details

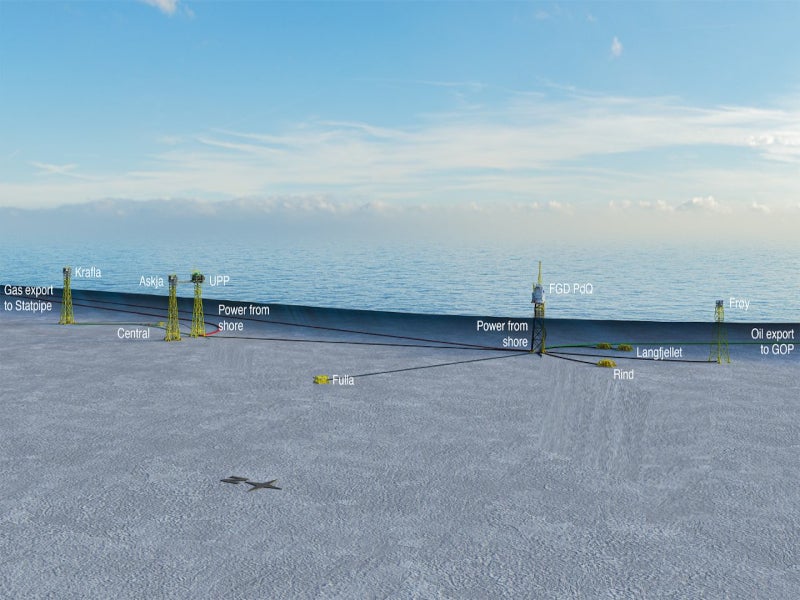

The Yggdrasil license area contains ten discoveries over a 60km long trend that stretches between Oseberg and Alvheim fields in the Norwegian North Sea. It is being developed and operated by Aker BP.

The license area includes the Hugin, Fulla, Munin, Frøy, Frigg Gamma Delta, Langfjellet, Lille-Frigg and Rind fields.

The area will be developed with an estimated investment of more than NOK115bn ($11.7bn) to extract the estimated reserves of 650 million barrels of oil equivalent.

Fulla field discovery and appraisal details

The Fulla field was discovered with the drilling of the 30/11-7 wildcat well in production licence (PL) 035 in 2009. The well was drilled to a vertical depth of 4,067m below the seabed in Lower Jurassic sandstone in the Drake Formation of the Brent Group, using the drilling facility West Alpha. The well proved a lean gas condensate in sandstones of the Ness Formation.

The discovery is estimated to contain approximately one million standard cubic metres (Sm³) to three million Sm³of recoverable oil equivalents.

An appraisal well 30/11-7A was drilled in the PL 035B to a vertical depth of 4,118m below sea level in Middle Jurassic rocks in the Etive Formation, using the Transocean Leader semi-submersible drilling rig in 2009. The well intercepted a 177m column of gas with approximately ten million Sm³ to 17 million Sm³ of recoverable oil equivalents.

The drilling of a well proved the accumulation of the main gas condensate in the Tarbert formation. Both wells are currently plugged and abandoned.

Lille-Frigg (PL 873) was discovered in 1975 and the field produced gas and condensate from the reservoirs located at 3,650m from the sandstone of the Jurassic age in the Brent Group. Production ceased in 1999 and the subsea infrastructure was removed in 2001.

The area containing the Fulla and Lille-Frigg fields includes the Tarbert Formation, which features a delta front and estuarine depositional environments, showing the best reservoir properties.

Fulla field development details

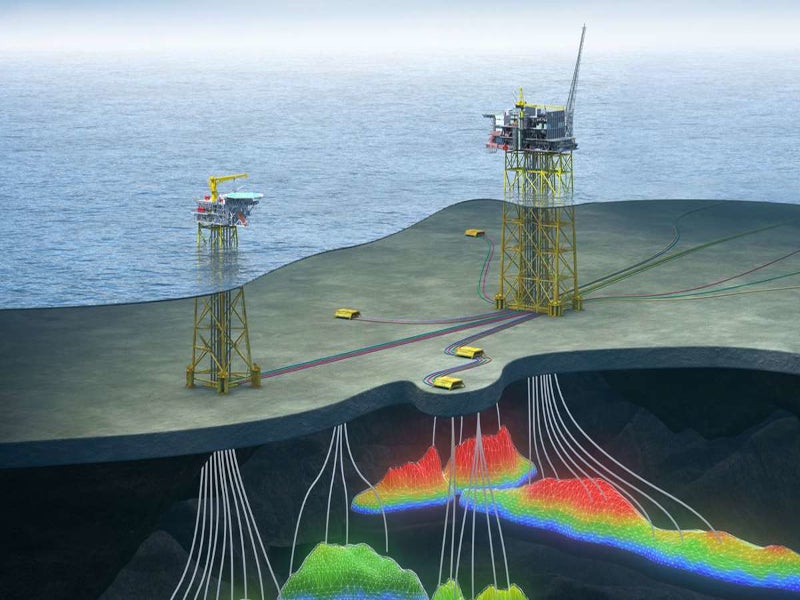

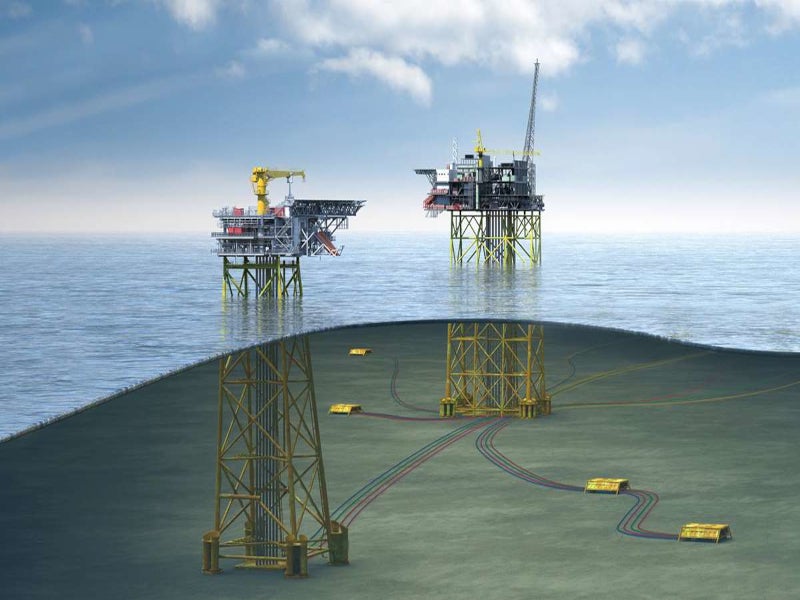

Fulla field will be developed as part of the Yggdrasil project through the Hugin A production, drilling and living quarters platform. It will also include the redevelopment of the Lille-Frigg field. Both the fields are planned to be developed with a six-slot subsea template tied back to the Hugin A platform.

Furthermore, the development will include the installation of a subsea production system, including wellheads, vertical subsea trees, a subsea control system based on Vectus™ 6.0 electronics module and other tie-in and connection systems.

Vectus 6.0 subsea electronics module

Vectus™ 6.0 is a next-generation subsea electronics module designed to remotely control offshore oil and gas production systems. It provides improved power capabilities and reduced implementation risks at oil and gas installations.

The system is designed as a future-proof solution to satisfy future industry requirements.

Fulla field power details

The field will be powered from the shore with a cable from Samnanger through a compensation station on Fitjar. The project will utilise a maximum of 150MW of electricity from the mainland grid, establishing itself as the world’s longest AC power connection from shore, spanning approximately 250km.

Oil and gas transportation details

Crude oil will be transported through a shared pipeline from Hugin A to the Grane Oil Pipeline, and subsequently directed to the Oseberg Transportation System (Sture). The transportation of gas will take place through a new gas export pipeline, accessible from both Hugin A and Munin and connected to Statpipe Area A and Karsto.

Contractors involved

In September 2021, energy technology company Aker Solutions was awarded a front-end engineering and design (FEED) contract as part of the Subsea Alliance for the installation of the subsea production systems for the Fulla field development. It was also awarded the FEED contract for the Hugin A platform as part of the Fixed Facilities Alliance.

The Fixed Facilities Alliance comprises Aker BP, Aker Solutions and Siemens Energy and is responsible for the development of fixed facilities, while the Subsea Alliance between Aker BP, Aker Solutions and Subsea 7 will develop the subsea production systems.

Aker Solutions was awarded an engineering, procurement and construction (EPC) and offshore hook-up contract for the Hugin A and Hugin B platforms. Previously, the company was also contracted to provide the pre-FEED services for the Fulla field development.

Aker Solutions subcontracted Leirvik, an offshore living quarters modules supplier, to provide FEED services for the living quarters and helideck of the Hugin A of the project.

Hitachi Energy, an energy company, was contracted to provide an onshore energy system and electrical equipment for the grid connection for the Yggdrasil area.

Allseas, an offshore contractor, was contracted to provide transportation and installation services for the Hugin A platform. Pioneering Spirit, an offshore construction vessel, is planned to be used for the same.

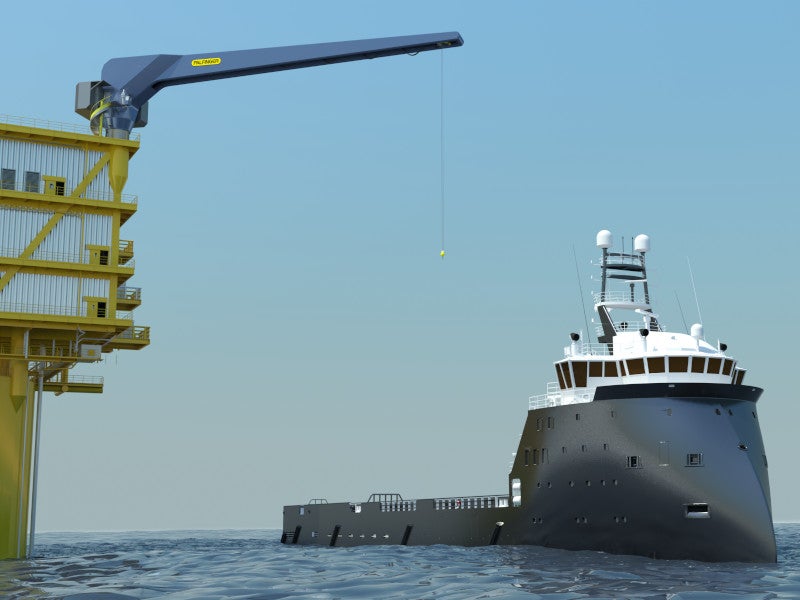

Palfinger Marine Norway, a mechanical engineering company, was contracted to provide remotely controlled cranes for the project.

Software companies Cognite and Aize will develop a digital twin for the project in cooperation with Aker Solutions. The two companies will deliver the digital solution as part of the NOA Digital project, a joint initiative with Aker Solutions and Aker BP.

Subsea 7, an engineering company, was selected to conduct the FEED study for the Fulla development project in September 2021.

Enersense, an energy solutions provider, was subcontracted by Aker Solutions to provide pre-assembled steel structure modules for the Hugin A platform.