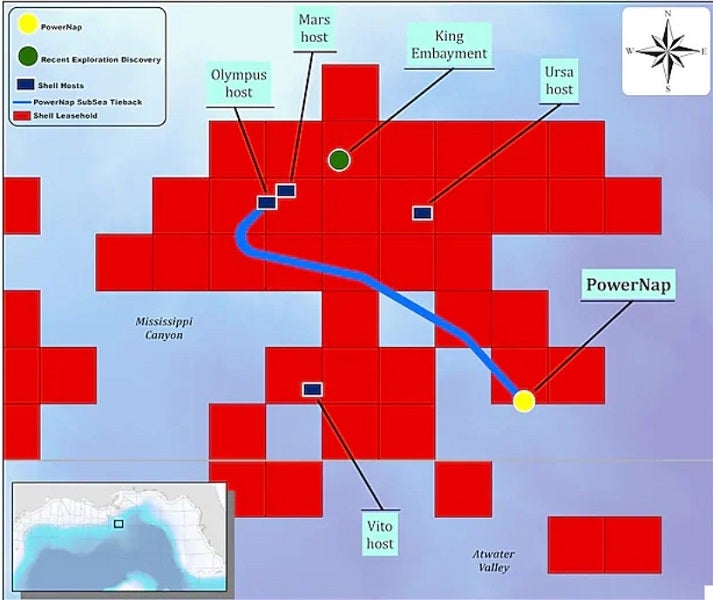

PowerNap is a deep-water offshore oil field being developed in the south-central Mississippi Canyon area in the US Gulf of Mexico, at a water depth of 1,280m (4,200ft).

The field is 100% developed by Shell Offshore, a subsidiary of Royal Dutch Shell, and was discovered in 2014. It is located about 240km away from New Orleans.

Shell Offshore reached a final investment decision (FID) to undertake the development of the project, in August 2019.

First oil from the field is expected to be produced in late 2021, with peak production projected to reach up to 35,000 barrels of oil equivalent per day (boepd).

Geology and discovery of PowerNap oil field

PowerNap is a three-way structural trap targeting sub-salt Miocene sand packages in Mississippi Canyon blocks MC943 and MC 944 in the Gulf of Mexico. It is located close to Vito oil field, which also lies in a large, deep sub-salt Miocene formation. It is estimated to contain recoverable resources of more than 85 million barrels of oil equivalent (Mmboe).

The exploratory well was drilled in the region to a total depth of 30,970ft and encountered hydrocarbons in December 2014. Drilled as part of the delineation drilling, two side-track wells confirmed the results in the initial well while extending the known downdip of the oil reservoir.

PowerNap oil field details

PowerNap will involve the development of three subsea wells, which will be tied back to the Shell-operated Olympus production complex. The production hub, co-owned by Shell (71.5%) and BP Exploration and Production (28.5%), flowed first oil in 2014.

The hydrocarbons from the field will reach the market through Shell’s Mars pipeline in the Gulf of Mexico.

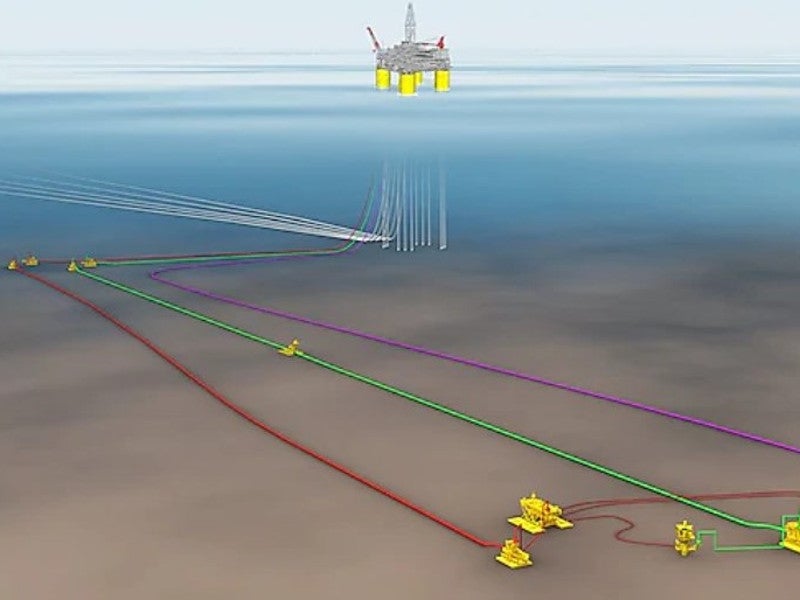

The subsea production system will include subsea tree systems and distribution controls, flying leads, topside controls, and connectors for the wells. The production umbilical and flowlines to be laid for the project will measure 32.1km long.

Mars pipeline details

The 262.3km-long Mars crude oil pipeline has a mainline capacity of 400,000bpd. It originates approximately 209.21km offshore Gulf of Mexico and carries oil produced from the Mississippi Canyon area to the shore for storage in salt dome caverns in Clovelly, Louisiana. The pipeline features 16in, 18in and 24in diameter lines. It is jointly owned by BP Midstream Partners (28.5%) and Shell (71.5%, operator).

The pipeline receives oil from the Olympus and Mars platforms, the Medusa and Ursa pipelines as well as from other connected production areas. Its connection to the Louisiana Offshore Oil Port (LOOP) storage and distribution hub provides producers with access to various downstream markets. It is designed to facilitate cost-effective connections with additional platforms and pipelines.

Contractors involved

TechnipFMC received an integrated contract to provide engineering, procurement, construction and installation (EPCI) services in August 2019. The contract, worth $75m-$250m, involves the design, production and installation of subsea hardware and the delivery of umbilical and flowlines.

Grand Isle Shipyard (GIS) partnered with Shell to provide human performance improvement and safety training for the PoweNap project.

Shell’s assets in deep-water Gulf of Mexico

Shell operates nine production hubs along with the associated subsea infrastructure network in the Gulf of Mexico.

In addition to PowerNap, the company has multiple active development projects in the deep-water of the Gulf of Mexico. The company’s deep-water portfolio includes the Mars B / Olympus project with a potential combined production capacity of 100,000boe/d.

Other key projects include Cardamom, Stones, and Appomattox developments. Shell also made the FID for the Vito project in 2018, which is anticipated to begin production in 2021.