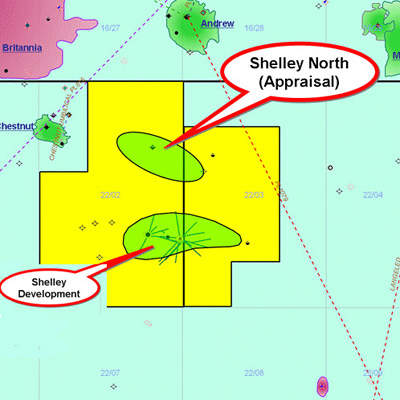

The Shelley field is located on Blocks 22/2b and 22/3a in the central North Sea, about 192km east of Fraserburgh, Scotland. It lies in 95m of water in a Paleocene Forties reservoir. Premier Oil was the 100% owner and operator of the field.

Decommissioning of the Shelley field

After achieving first oil in August 2009, reservoir pressure at the field dropped significantly in the next few months. The amount of produced water also increased hence the decision to cease production at the field was made in July 2010.

Premier Oil submitted a decommissioning programme for the field as per the Petroleum Act 1998. The programme was approved in June 2010 and included four phases. The first phase included suspension of production and removal of the FPSO. Phase two and three included removal of the subsea facilities and phase four focused on well abandonment. These phases were carried out in 2010 and 2011.

Discovery and award to Oilexco North Sea

The field was discovered in 1984 by the 22/2-2 well and then plugged for 20 years until it was awarded to Oilexco subsidiary Oilexco North Sea Ltd (ONSL) in 2005.

In October 2007, Diamond Offshore’s Ocean Guardian semi-submersible drilled eight well penetrations from a single subsea well bore to appraise the discovery. Several appraisal wells were then drilled to further define the area.

The appraisal well 22/2b-13 reached a true vertical depth of 4,221m. It tested at a rate of 3,082 bopd at more than 31º API. Further appraisal drilling was carried out on well 22/2b-13 to determine the size of the reservoir, which was found to measure 7km².

The final appraisal well, 22/2b-13t, was tested through 13m of perforations representing five true vertical metres of perforated reservoir from the top of 10 vertical metres of oil pay. The well tested at a flow rate of 3,082bopd at a 36/64in choke. The findings confirmed the previous discovery from 22/2b-13.

Estimated total recoverable reserves for the field were 20Mmbbl of oil.

Development by Sedco 712 semisub

In 2008, the Sedco 712 semisub, which is owned and managed by Transocean, began Shelley’s development drilling.

In May 2009, Premier Oil took over as the operator and owner of Shelley as part of its acquisition of ONSL for $505m. Earlier, in April 2009, Sevan had entered into a memorandum of understanding with Premier for the continued provision and operation of Sevan Voyageur floating, production, storage and offloading (FPSO) vessel, which Oilexco had contracted to operate for a fixed term of five years. The memorandum granted Premier or one of its affiliates continued use of the vessel in the event Oilexco or the Shelley field was sold.

Production began in early August 2009 at an initial rate of 10,000-12,000 barrels of oil per day. Premier developed the field using two horizontal subsea production wells equipped with downhole electric submersible pumps. The wells were connected via a short flowline, and a control umbilical, to Sevan Voyageur. The wells and infrastructure were monitored, controlled and operated from the FPSO.

The oil was separated from gas and water on the FPSO. Water injection was considered at one stage but ultimately dropped, so produced water was cleaned up to relevant standards and discharged into the sea. Part of the gas was used as fuel to generate power and the rest was flared off. The oil was stored in the FPSO, then transferred to a shuttle tanker for transport onshore to an unnamed refinery.

Sevan Voyageur FPSO

The Sevan Voyageur FPSO was built at the Yantai Raffles shipyard in Shandong, China. It was transported to Bergen Group’s Hanøytangen shipyard for rigging up and engineering of various structures, then to Rotterdam for topside hook-up and commissioning in the last quarter of 2007. It arrived at the field in November 2008 to be hooked up to a pre-laid mooring system.

The Sevan Voyageur, at 66m long and 60m wide, has a displacement of 50,000t. It has a production capacity of 35,000 barrels of oil per day and a storage capacity of 300,000 barrels of oil.

Being a cylindrical FPSO, it can operate more efficiently in harsher climates on fields of various sizes because of its flexible design and motion characteristics. The round vessel has less hull surface, which reduces the amount of steel needed for construction, but it contains the same storage volume as that of traditional FPSOs.

Sevan Voyageur FPSO was removed from the field in the 2010. It was later refurbished and moved to E.ON’s Huntington field.

Contracts

In 2008, Technip was awarded a $242m contract for the engineering, installation and commissioning of pipelines for the field. The contract covered the control umbilicals and jumper, the flexible risers, the subsea manifold and an attendant flowline.

Technip won the contract for the first phase of decommissioning works at the field. This phase was completed in 2010. Technip also won a £4.4m ($6.87m) contract for the second phase of decommissioning in June 2011. The scope of the contract included decommissioning and recovery of a 2km long electro-hydraulic control umbilical, three production flexible jumpers, and two well control jumpers. It also included decommissioning 121 concrete mattresses, and manifold structure.

In March 2011, Semar was awarded with a contract to remove 12 suction anchors at the field. The anchors were used for mooring Sevan Voyageur FPSO.

EPC Offshore was contracted to define the phases of decommissioning and managing the decommissioning operations at the field.

iSURVEY supported Sevan Marine in the decommissioning of FPSO at the field. The scope of the work included providing survey personnel and equipment for disconnection of mooring system and supporting towing vessels.