The Scarborough gas field is located approximately 270km north-west of Onslow in the Carnarvon Basin of the Northwestern Shelf, offshore Western Australia. The field lies in the WA-1-R license, in water depths between 900m and 1,500m.

The Scarborough gas project includes the development of the Scarborough and North Scarborough fields, as well as the Pluto Train 2 liquefied natural gas (LNG) train.

The WA-1-R license was previously owned by ExxonMobil subsidiary Esso Australia Resources (50%), BHP Billiton (25%) and Woodside Petroleum (25%). Woodside acquired ExxonMobil’s 50% interest in the license in March 2018.

The Scarborough gas project is developed by the Scarborough Joint Venture, comprising Woodside Energy Scarborough (73.5%) and BHP Petroleum (Australia) (26.5%). The final investment decisions for the Scarborough and Pluto Train 2 projects were completed in November 2021.

Woodside completed the transaction for a sale and purchase agreement with Global Infrastructure Partners (GIP) for a 49% non-operating participating interest in the Pluto Train 2 Joint Venture in January 2022. Under the joint venture arrangements, GIP will provide an additional $835m of funding for the project’s construction.

Discovery, geology and reserves

The gas field was discovered by the Scarborough-1 well, which was originally drilled in 1979 at a water depth of about 900m. The field is a simple anticlinal structure located at depths of approximately 1,800m.

Its reservoir comprises high-quality gas accumulated in the Barrow Group Flag sandstone of the Zeepaard Formation.

The gas contained within the field is classified as ‘sweet’, without traces of hydrogen sulphide and only trace levels of carbon dioxide. The field is estimated to contain 11.1 trillion cubic feet (tcf) of dry gas.

The field’s reserves are considered to be one of the most remote gas resources in the Carnarvon Basin.

Appraisal drilling

A seismic survey of the field was completed in 1996, which covered an area of 2,440km². The survey was conducted before the commencement of the appraisal well drilling programme.

The first appraisal well to be established at the field was known as Scarborough-2 and drilled in June 1996 to a total depth of 2,068m.

BHP Billiton carried out a 3D seismic survey spanning 912km² at the field in 2004, which was followed by a three-well appraisal drilling programme started in December of the same year.

The appraisal drilling was conducted until early 2005 and involved the drilling of three appraisal wells, named Scarborough-3, Scarborough-4A and Scarborough-5.

Scarborough gas field project development details

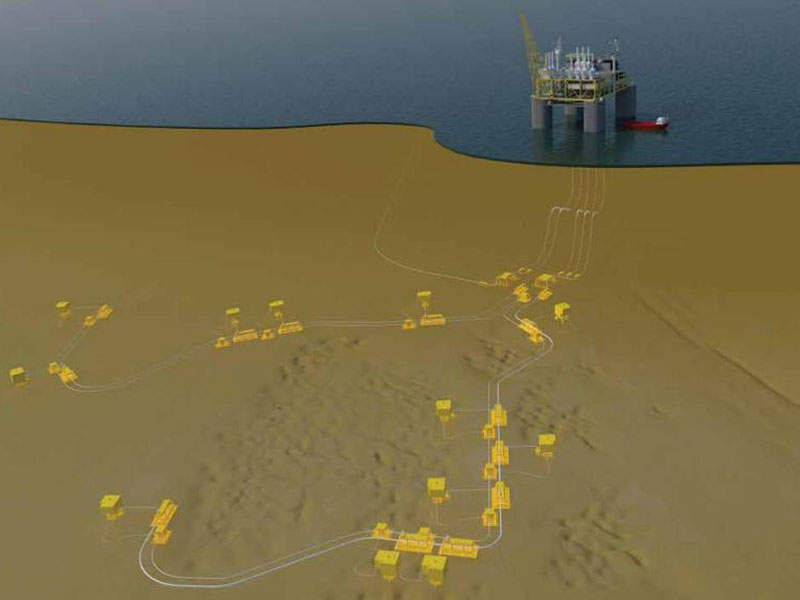

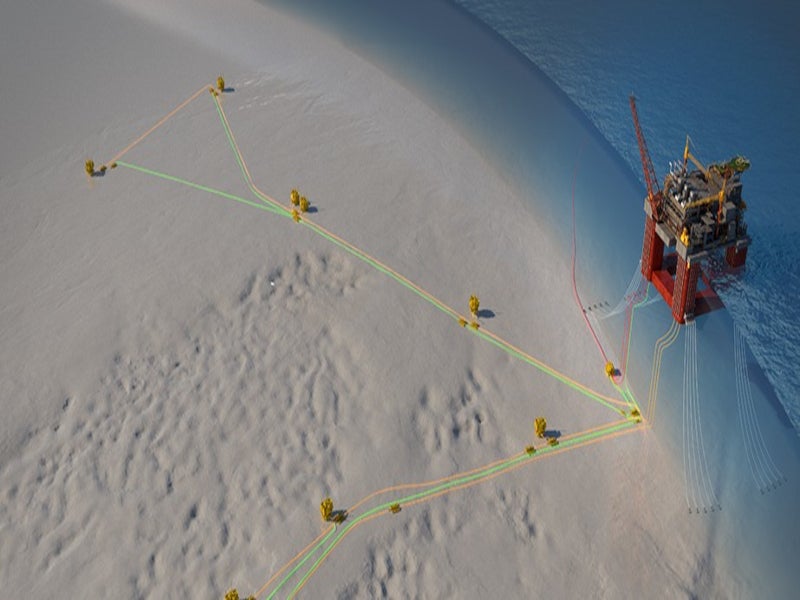

The Scarborough gas field will be developed through the drilling of eight wells in the initial phase and 13 additional wells throughout the life of the field. The wells will be tied back to a new semi-submersible floating production unit (FPU) moored through a semi-taut mooring system at a water depth of 950m in the Scarborough field. The minimally manned FPU will have remote control operation capabilities.

Development wells will be drilled to depths of approximately 3,000m beneath sea level.

Drilling of the first eight wells will be undertaken by the Valaris DPS-1 mobile offshore drilling unit. Wells will be grouped into drill centres to optimise the layout and possible future tie-ins for the Thebe and Jupiter gas fields.

The subsea infrastructure will include 45km of rigid flowlines, six flexible flowline risers, 42km of umbilicals, eight trees and associated subsea equipment. The subsea infrastructure will be powered, monitored and controlled from the FPU by a network of electro-hydraulic control umbilicals and subsea distribution units (SDUs).

Onshore development details

Processed gas from the platform will be transported through a 430km-long carbon steel pipeline to Pluto Train 2, which will be the second LNG train at the existing Pluto LNG onshore facility, located on the Burrup Peninsula and covering an area of 80ha. Construction of the trunkline is anticipated to begin in 2022.

The Pluto LNG facility, operated by Woodside, was commissioned in 2012. It comprises a single LNG processing train, which runs at a production rate of approximately 4.9 million tonnes per annum (Mtpa).

Pluto Train 2 will have an LNG capacity of approximately five Mtpa. As part of the construction, additional domestic gas infrastructure will also be installed, increasing the capacity to approximately 225 terajoules a day.

Besides processing approximately five Mtpa of gas through Pluto Train 2, up to three Mtpa will be processed through the existing Pluto Train 1.

Contractors involved

Ocean Infinity was contracted by Woodside to provide deepwater geophysical survey data for the Scarborough offshore field development.

Wood was awarded a contract by Woodside in August 2018 to support the execution of concept definition related to the FPU, sea umbilicals, risers and flowlines, flow assurance, and associated equipment for the Scarborough gas field development project.

McDermott was awarded the front-end engineering and design (FEED) contract for the FPU, which was set to be installed at the Scarborough project in February 2019.

Woodside awarded a FEED contract to Bechtel for the second train at the Pluto LNG facility in December 2018.

The FEED contracts for the modifications to Pluto Train 1 were awarded to engineering companies Kellogg Brown and Root and Bechtel in January 2022.

The Subsea Integration Alliance, which is a non-incorporated strategic global alliance between Subsea 7 and OneSubsea, a division of Schlumberger, received the contract for engineering, procurement, construction and installation (EPCI) of subsea pipelines and production systems for the project in December 2021.

ABL Group was appointed to provide marine warranty services (MWS) for the construction, transportation and installation work on the project in May 2022.

EUROPIPE will supply 300,000t of large-diameter pipe for the trunkline, while Saipem will complete the export trunkline coating and installation of the pipeline, connecting the Scarborough gas field and the onshore facility.