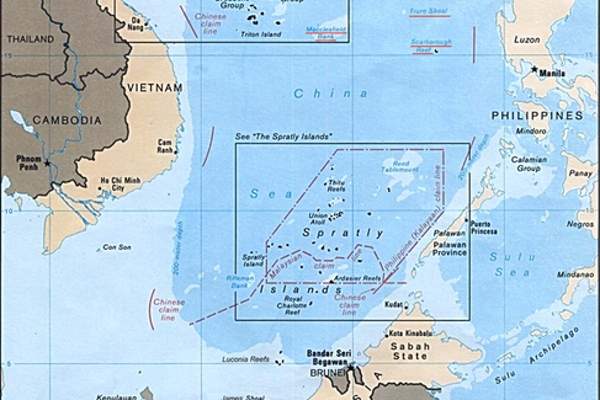

The Siakap North-Petai (SNP) field is located in block K on the west coast of Sabah in Malaysia. It lies eight miles northeast of the Kikeh floating production, storage and offloading (FPSO) vessel, at a water depth of 4,429ft in southern part of South China Sea.

The field is operated by Murphy Oil, which holds 32% interest. Other partners in the field development include PETRONAS (26%), ConocoPhillips (21%) and Shell (21%).

Production and reserves at the Malaysian offshore field

First oil production from the Siakap North-Petai field occurred in February 2014. The initial production commenced from four oil wells. The production is expected to peak to 35,000 barrels of oil per day (bpd) by mid-2014.

Discovery and development of Siakap North-Petai field

Siakap North located in Block K was discovered in 2009 by Diamond Offshore’s Ocean Rover semi-submersible rig. Petai, located near block G, was discovered in 2007.

Murphy along with the other development partners decided to unitise the discoveries and develop them as a single field. The unitisation of Petai and the Siakap North Field in Block K was completed by 2011.

Geology

The SNP field is situated on the west coast of Sabah in the South China Sea at a water depth between 1,200m and 1,500m. The sea bed on the southern and northern half consists of two different geologic characteristics. The southern half features soft and rounded seabed, while the northern half contains high reliefs.

The samples collected from the seabed showed the presence of soft and greenish clay. Major constituents of silt and clay, and little amounts of fine sand were found in all the sediment samples conducted on the field seabed.

The infrastructure and storage facilities at the field

The field is being developed with eight subsea production wells and five water injection wells. It will produce oil from a total of four subsea drill centres. The production from each drill centre is gathered at the production manifolds and then moved through a dual production pipeline system to the Kikeh FPSO owned by MDFT Labuan.

The subsea systems on both Siakap North and Petai fields are unitised and tied back to the Kikeh FPSO, which has a storage capacity of about 120,000bopd.

Contractors involved

McDermott was contracted to provide engineering, procurement, construction and installation, transportation and commissioning of subsea infrastructure at the SNP field. The scope of work included providing two rigid insulated pipe-in-pipe production flow lines, one rigid water injection flow line, and one main umbilical system connecting new manifolds and subsea distribution units to the existing spare riser slots in the Kikeh FPSO.

The subsea installation work commenced in January 2012 and was completed in 2014.

The fabrication works of all the subsea structures was completed at Port Klang and Batam facilities. The design, construction, installation and engineering support for the subsea systems were provided from McDermott’s Singapore and Houston facilities. The procurement activities were executed from Singapore.

The vessels used for the installation of rigid pipe-in-pipe production flow lines, flexible risers, and rigid water injection flow lines included LV North Ocean105, 102, Emerald Sea, and a third-party ROV construction support vessel.

Aker Solutions was awarded a contract in May 2012 to provide subsea production system for the SNP field development. The scope of the contract included offering subsea trees, manifolds and well jumpers in addition to providing engineering for the topside controls, and lifecycle support services.