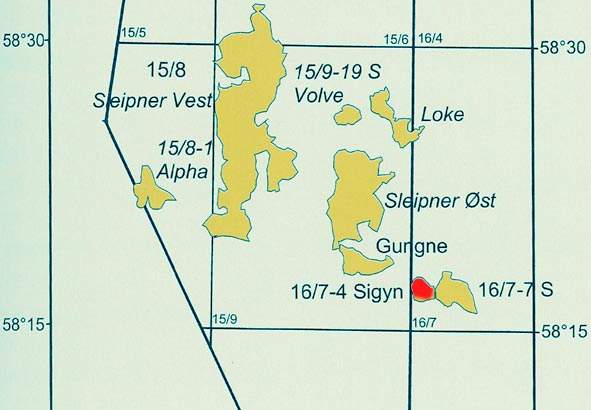

Sigyn is a gas and condensate field located at a water depth of 70m, in block 16/7 in the central part of Norwegian North Sea, approximately 12km south-east of the Sleipner A platform.

Equinor Energy, the operator of the field, has a 60% stake, while the remaining 40% is held by ExxonMobil Exploration and Production Norway (40%). The operatorship of the field was transferred from ExxonMobil Norway (Point Resources) to Equinor in July 2017.

The project was developed with an investment of approximately Nkr2.9bn ($324m) and an additional Nkr5m ($0.6m) is anticipated to be invested in the project.

The plan for the development and operation of the field was approved in 2001 and production started in 2002. The field was expected to produce for a period of ten years, but later the production phase was extended till 2022.

Licence

The production license 072 was awarded in 1981 and the field was discovered in 1982 before being added in 1997. The license is valid until December 2022.

Gas reservoirs and reserves

The gas and condensate in the field is produced from two individual deposits, namely Sigyn West and Sigyn East, present in the Triassic sandstone at the Skagerrak Formation. Sigyn West contains the gas and condensate deposits, while Sigyn East contains light oil. The reservoir is present at a depth of 2,700m in the seabed.

Sigyn’s reserves include 5.6 billion standard cubic metres of gas, 2.6 million tonnes (Mt) of natual gas liquids (NGL) and 5.6 million standard cubic metres of condensate.

The Norwegian authorities allocated Sigyn to supply 2.3 billion cubic metres of gas during 2002 to 2003 as part of a gas sales contract that was agreed in June 2001. The field was recovered using pressure depletion and is currently in the tail phase of production. Gas injection process is being tested in the Sigyn West and Sigyn East deposits to improve recovery.

Sigyn field development details

The Sigyn field was developed using a subsea template with three wells tied to the Statoil-operated Sleipner A facility via two flow lines.

The subsea production systems comprising control systems, Christmas trees, wellheads and related seabed equipment were also installed. The production can be remotely operated from the platform.

Dry gas from the Sleipner A facility is exported to the market utilising Sleipner Riser via Gassled pipeline infrastructure (Area D). The condensate is transported to Karsto terminal of Stavanger through a dedicated pipeline.

Sleipner A facility details

The Sleipner A facility houses an integrated production, processing and accommodation platform, comprising two business units, a Sleipner Ost unit and a Sleipner Vest unit. The Sleipner Vest was discovered in 1974 and is located at the water depth of 110m. The Sleipner Ost, located 82m in water, was discovered in 1981.

With the total base area of 16,000m2, the facility features a Condeep type platform with concrete gravity base structure and 24 cells.

The original hull of the facility sank during lowering in water due to a flaw in the design in August 1991. However, it was redesigned and installed successfully in June 1993.

Contractors Involved

Statoil signed multiple contracts worth Nkr289m ($30.6m) for the site’s development in July 2001. These included a subcontract to FMC Kongsberg Subsea worth Nkr210m ($23.2m) for engineering and construction of the subsea production systems, a Nkr7m ($0.7m) contract to Reinertsen Engineering for pipeline system engineering, and an approximately Nkr70m ($7.4m) contract to Itochu for delivering material for two flow lines.

Another group of contracts worth Nkr375m ($42.8m) were signed in October 2001. The contracts included an Nkr200m ($23m) contract to ABB for the modification of Sleipner A platform to connect Sleipner A with the Sigyn field.

An Nkr175m ($19.9m) contract was secured by Coflexip Stena Offshore to install a seabed template, flow lines and control system.