Discovered in February 2003, the Stybarrow oil field is located in licence block number WA-32-L in the Exmouth sub-basin, approximately 65km from Exmouth, off the north-west Australian coast.

Stybarrow and the adjacent small oil rim of the Eskdale field, have recoverable reserves estimated to be in the range of 60 to 90 million barrels of oil. First production, which came from Eskdale, was announced in November 2007. The estimated economic field life was due to be ten years, but BHP Billiton is to carry out 4D seismic studies to ensure its continued viability.

BHP Billiton operates the field with a 50% interest; the other 50% held by Woodside Energy Limited. Water depth is approximately 825m, making it Australia’s deepest oil field development. Stybarrow’s project costs were approximately A$760m, which included the cost of field development.

Stybarrow drilling

The Stybarrow field was discovered in February 2003, when the Stybarrow-1 well, drilled in the Macedon member sandstone reservoir, encountered a gross oil column of 23m with 18.6m of net pay. This was followed by further wells on Eskdale-1 (March 2003), Skiddaw-1 and Skiddaw-2 (May 2003) and Stybarrow-2 (June 2003).

BHP Billiton then carried out an appraisal programme, notably Stybarrow-3, 2km north-east of Stybarrow-1 where it encountered a gross oil column of 6.5m, and the sidetrack well Stybarrow-4 which intersected a 16m gross oil column. It also carried out two further exploration wells in a water depth of 830m; Eskdale-2 which encountered a gross oil column of 13m and a gross gas column of 24m and Knott-1.

Nine wells were drilled by the semi submersible rig Atwood Eagle – seven subsea wells for the production of hydrocarbons, one well for the production of hydrocarbons from the Eskdale field and a further well for the injection of excess gas in the Eskdale field. The drilling programme took around nine months

FPSO Stybarrow Venture MV16

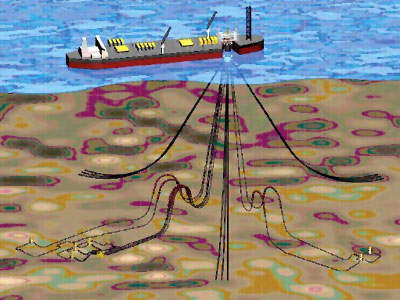

The subsea production wells are tied back into a floating, production, storage and offloading (FPSO) vessel. Called the FPSO Stybarrow Venture MV16, the disconnectable, double-hulled unit is owned and operated by MODEC.

The hull was built in Korea and then sailed to the Jurong shipyard in Singapore, where the topsides were integrated in a six-month programme.

The FPSO has a storage capacity of 900,000 barrels, a total liquid process capacity of 100,000bpd, a crude production capacity of 80,000bpd, and gas production capacity of 45 million standard cubic feet per day. It has an internal disconnectable turret which was provided by SOFEC. This enables the FPSO to evacuate if a cyclone were to develop in the area.

Just such an eventuality occurred in February 2008, when tropical cyclone Nicholas hit the area.

As a marketable crude oil, Stybarrow will be sought after because of its blending characteristics, its low sulphur, low contaminants and moderate acid, making it a crude oil of choice for North Asian customers.

Stybarrow installation programme

The seabed at the well centres has been found to comprise very soft sand / silt and carbonate clays of 10m to 20m thickness. The subsea anchors and mooring system for the FPSO were laid using the Normand Mariner between December 2006 and January 2007 and the flowlines were then laid ready for the arrival of the production vessel.

Subsea 7 and Technip were awarded the subsea EPIC installation contract, valued at over $160m. This included the design, manufacture, transport, installation and pre-commissioning of approximately 48km of flexible risers, flowlines and jumpers fabricated at Technip’s flexible manufacturing facilities in Le Trait, France.

The contract also included the transport, installation and pre-commissioning of around 16km of dynamic and static umbilicals and associated electrical and hydraulic flying leads as well as the installation of the FPSO spider buoy and mooring system complete with anchors.

The offshore programme started in early 2007 using Technip’s construction vessel, the Deep Pioneer, assisted by the CSO Venturer. Two Heavy Lift Vessels (HLVs) were contracted to transport the flexible flowlines and other subsea equipment.

Full ramp-up and production was expected to take several months after first oil, but in January 2008 BHP Billiton announced that Stybarrow had already achieved sustained production levels at the planned capacity of 80,000bpd.

At the time, the company said one well alone had been operating at about 32,000bpd – close to a record for Western Australia – and that in the two months since production began Stybarrow had offloaded a total of 2.5 million barrels of oil.

The company said this was based in part on the use of real-time monitoring technology to control and manage the flow from individual wells. Downhole and subsea tree pressure and temperature gauges have allowed engineers to manage the drawdown to maximise production and ensure prudent management of the reservoir. The technology has also improved the operating efficiency of the FPSO topsides facilities, it said.

Seismic studies

In late October 2008, BHP Billiton announced it was gearing up to conduct baseline 4D seismic studies at the Stybarrow to resolve uncertainties in the operation.

The reasons behind this move remain cloudy. BHP Billition maintains that there are no problems at the oil field but, contradicting this, is a referral notice to the federal Environment Department that states failure to do the studies would, “threaten the viability of the overall development of the Stybarrow field”. In addition, the referral says that the move is needed to “resolve some uncertainties around the Stybarrow reservoir dynamics”.

An original application to conduct 4D studies was submitted in May but was delayed due to humpback migration season and safety issues in the vessels. At the time, BHP said the studies were needed due to uncertainties associated with the interpretation of results and recent developments in the Stybarrow production and gas injection profile.

In total, BHP Billiton spent $148m on petroleum exploration for the third quarter of 2008 ending in September.

“The field produced an average of 72,900 barrels per day in the quarter ended 30 September 2008 compared to 77,313 bpd in the second quarter of 2008,” said field partner Woodside Petroleum, which added that natural field decline set in during the month of September.