The Tamar field is an offshore gas field located in the Levantine basin of the Eastern Mediterranean Sea, Israel. Noble Energy was the original operator of the field until Chevron acquired the company in 2020.

The project partners are Chevron Mediterranean (operator) with a 25% stake, Dor Gas (4%), Everest Infrastructure (3.5%), Isramco (28.75%), Mubadala Energy and Tamar Investment 2 with 11% each, and Tamar Petroleum (16.75%).

Discovered in 2009, the Tamar field commenced production in March 2013. In January 2017, it began supplying natural gas to the Arab Potash Company and the Jordan Bromine Company, marking the first natural gas export agreement approved by the Israeli government.

The field’s production capacity currently stands at 1.1 billion cubic feet per day (bcf/d).

Project location

The Tamar gas field lies within Licence Block 309, known as the Matan Block, approximately 90km west of Haifa. It is situated at a depth of 5,000m below sea level, at water depths reaching up to 1,700m.

The field spans an area of 100km² and has reservoir layers that reach up to 300m in thickness.

Reservoir and reserves

The Tamar reservoir holds a reserve of dry gas with a methane content of up to 99% and is characterised by high porosity and permeability, as well as strong connectivity between different sections of the reservoir.

As of September 2021, the Tamar field was estimated to hold 300 billion cubic metres (bcm) of natural gas and 14 million barrels (Mbbl) of condensate in 2P reserves.

Tamar field details

The Tamar field originally comprised five wells connected to a single subsea manifold. The wells, Tamar-1 through to Tamar-6, were completed in 2012. Tamar-6 was a re-drill/completion of the Tamar-1 well and an additional well, Tamar SW-1, was drilled in the Tamar Southwest Reservoir in 2013.

The Tamar production platform was installed in 2013 close to the existing Mari-B production platform. Gas produced from the Tamar platform is delivered to the Ashdod onshore terminal through a 30-inch export line for final treatment.

Currently, wells Tamar-2 through to Tamar-6 are producing and two subsea gathering pipelines carry gas from a subsea manifold to the Tamar processing platform.

Tamar field expansion details

Tamar field operating partners in Tamar reached a final investment decision for the first phase of a two-phased expansion for the field in December 2022.

The first phase of the expansion involves an investment of $673m for the addition of a third gathering pipeline from the subsea manifold to the Tamar production. The platform’s production equipment will also be upgraded as part of the first expansion phase.

The new pipeline system will comprise 20-inch longitudinally submerged arc welded steel pipes, which will increase the daily production capacity from 1.1 billion cubic feet (bcf) to approximately 1.2bcf.

The second phase of the expansion will leverage existing, currently unused compressors with the aim of further increasing the maximum daily production capacity to 1.6bcf. Two potential sites that can be considered for the expansion are located in Jordan and Ramat Hovav, an industrial zone in southern Israel.

Contractors involved

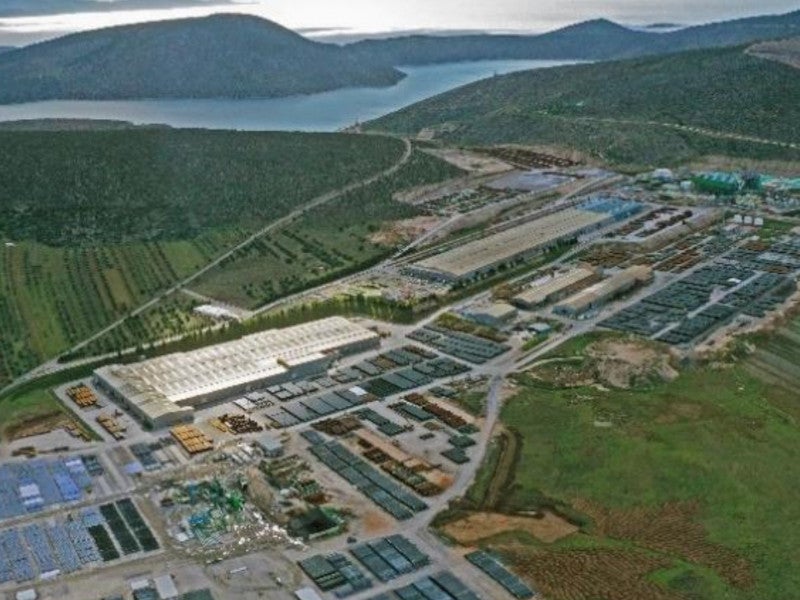

Chevron awarded the deepwater Tamar optimisations project to Corinth Pipeworks, the steel pipes segment of Cenergy.

The pipes will be manufactured at Corinth Pipeworks’ facilities in Thisvi, Greece, with installation work scheduled to commence in 2024. The scope of supply also includes internal and external three-layer polypropylene coating.