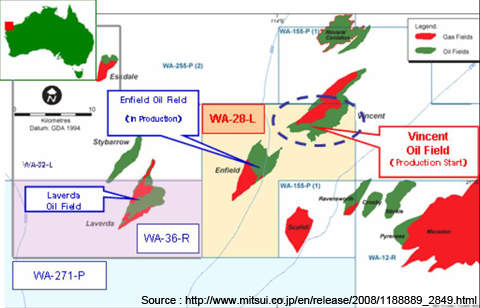

Vincent oil field lies in production licence WA-28-L, 50km offshore Exmouth in Western Australia. Operated by Woodside Energy, the field is situated at a water depth of 350m. Woodside holds a 60% interest in the field with the remaining 40% being held by Mitsui E&P Australia.

Oil production from the field started in August 2008. The production rate in 2010 was 25,000 barrels per day (b/d). The partners invested $720m in developing the field.

Discovery

The Vincent field was discovered in 1998 by a discovery well that encountered a 12M-19m-thick oil column. Two appraisal wells, drilled after the discovery, confirmed the presence of hydrocarbons.

Geology and reserves

The Vincent field reservoir is in the Lower Barrow Group and contains fluvio-deltaic sandstones.

Estimated recoverable reserves are 73 million barrels. The oil is heavily biodegraded with an API of 17°.

Field development

In December 2005, Woodside submitted the plan for development of the field. Woodside and Mitsui made the final investment decision on the project in May 2006.

The field is being developed in phases, with the first phase comprising 11 wells: eight production wells, two water injectors and one gas-injection well.

Production

The field is produced by eight subsea production wells tied to two different manifolds, which are in turn connected to the Maersk Ngujima-Yin FPSO.

The recovered gas and produced water are injected back into the reservoir below the ocean floor for production stabilisation and to reduce carbon dioxide emissions. The re-injection is carried out using high-pressure pumps.

Maersk Ngujima-Yin FPSO

The Ellen Maersk very large crude carrier was converted into the Ngujima-Yin FPSO. The cruder carrier was constructed in 2000 by Hyundai at its Ulsan shipyard in Korea.

The FPSO is 333m-long and 58m-wide with a capacity of 308dwt. It was converted at the Keppel shipyard in Singapore.

The vessel features a double hull and detachable submerged production system (STP) turret-mooring system. Additional risers and turret swivels are provided for future development. The production capacity of the vessel is 120,000b/d and loading capacity is approximately 2.1 million barrels. Storage capacity is 1.2 million barrels of oil.

Contracts

Maersk Contractors signed a seven-year contract to design, construct and operate the FPSO with an option to extend in May 2006.

Maersk subcontracted Vetco Aibel to fabricate the topsides process modules on the FPSO. Vetco Aibel supplied a water-injection unit, gas compression and treatment unit, and utility and power modules.

In November 2006, Technip was contracted to supply the field subsea equipment including rigid spools, flowlines, risers, production umbilicals and high-voltage electrical jumpers.

APL was subcontracted by Maersk Contractors to supply the STP turret-mooring system for the FPSO. APL’s work included fabrication, installation and commissioning of the turret-mooring system.

ABB supplied integrated control and safety modules for the FPSO. The company also supplied an electrification distribution unit for the process module.

Clough AMEC was awarded a contract to provide engineering and fabrication services for the FPSO.

Acergy won a $40m contract to transport and install a single-turret buoy system for the FPSO. The company also installed a subsea manifold and multi-phase pump structures.

In January 2007, FMC Technologies was awarded an $81m contract to supply 11 vertical subsea trees and related systems, and two production manifolds. FMC Technologies was also awarded a contract for supplying subsea equipment for the FPSO in 2005.

Using its rigless intervention technology, TSmarine installed subsea trees and wireline intervention on the subsea wells at the field as part of a multi-year agreement signed with Woodside. TSmarine executed the project in partnership with WellOps SEA and Schlumberger.

In August 2010, Trelleborg Offshore supplied its Elastopipe deluge system to replace the pipework on the FPSO.