ECF Special Alloys is a specialised exotic metals fabricator for the offshore and petrochemical industries. The company was established in 1993 and gained approval to BS EN ISO 9001 in 1995. In 2009 we achieved ASME U stamp accreditation for the fabrication of pressure vessels to ASME VIII Div 1. In addition to our fabrication service we offer a full subcontract design and drawing package. The company has an ongoing commitment to maintain and improve the high quality and standards required by our offshore and petrochemical customers.

Our extensive understanding of the exacting standards required by the offshore industry enables us to provide you with an excellent service. We pride ourselves on our ability to meet these exacting standards and the often short delivery requirements of the marketplace.

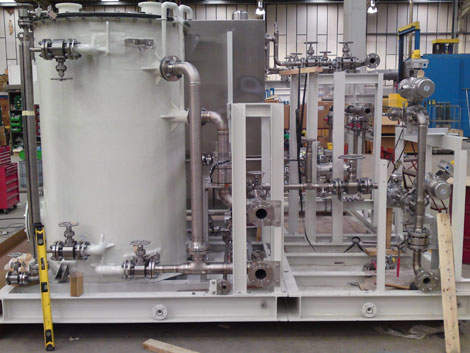

High-quality fabrication services for the offshore industry

ECF has a large, modern fabrication shop, which is 10,000ft² in size. Working with materials such as high-nickel alloys means that our workshop operates as a ‘clean shop’ with a 10t overhead crane facility. Our capabilities are as follows:

- Ten coded welders and six time-served process plant fabricators

- Testing: X-ray, UT, DPI, PMI

- Pressure testing facility

- Indoor / outdoor storage

- Dedicated clean working area for non-ferrous alloys

- Welding processes – TIG, MMA, MIG

- Fabrications: up to 10t and in sizes up to 6m

Fabrication of specialist materials

ECF is able to offer fabrication and welding services for the following materials: Titanium, Hastelloy, Inconel, Incoloy, Zeron 100, Super Duplex, Duplex, Stainless Steel – 316L and 304L, 6MO, Cupro Nickel, Monel, Aluminium Bronze, High-Tensile Carbon Steel, and Low-Temperature Carbon Steel.

Fabrication services for offshore equipment

Over the past 17 years ECF has manufactured many parts for the offshore industry. Our highly skilled project and production team has a wealth of experience in dealing with complex and difficult fabrication issues, and we pride ourselves on our can-do attitude and solutions-driven approach to sometimes complex fabrications.

We have manufactured:

- Pressure vessels

- Shell and tube heat exchangers

- Turbine shaft assembly

- Filters

- Flame arresters

- Impellers

- Valves

- Magnetic and ultrasonic flowmeters

- Vessels

- Pipework and fittings

- Columns

- Coils

- Dip pipes

- Spargers

- Heating pipes

- Hoppers

Our welding methods include TIG, MMA and SYNERGIC MIG.

Fabrication and welding expertise

ECF’s staff has experience in fabrication techniques for all types of pipework, heat exchangers, filters and pressure vessels. The company operates according to the following standards:

- Welding standards: ASME IX (U stamp approved), BS EN ISO15614-1:2004 and NORSOK M601

- Fabrication standards: ASME VIII Div 1 and PD5500:2009

What our customers say:

- The company does what it says on the tin

- Always meet deadlines

- ECF’s personal working relationships with its customers are key to the project success

- With a management team with a combined 100 years of experience, we have confidence in their ability to deliver

- Reliable service, reliable quality and honest in their estimations

- They just get on with it and good communication means we are always informed of what stage the project is at any time

- They deliver – no matter what the deadlines are

Cost-effective offshore fabrication services

ECF welcomes your enquiries for any of its services and to discuss your ongoing projects. We welcome the opportunity to provide a cost-effective fabrication service as your approved fabrication partner.

ECF can provide support for your offshore projects. Assisting in design, producing quality fabrications, and utilisation of its highly skilled project management team means that your project will be delivered on time and on budget.

Offshore fabrication and profiling services

ECF offers fabrication pressing and rolling, both up to 50mm thick. Our prolifing services include plasma, laser and water jet.

Offshore machining services

We offer vertical boring, horizontal boring, CNC turning and milling, slotting, and drilling services for the offshore industry.

Offshore NDT services

Our NDT services include X-ray / gamma, DPI MPI UT and PMI.

Finishing services for offshore equipment

ECF provides a range of finishing services for offshore equipment, including rubber lining, bead and shot blasting, painting, pickling, electro plating and metal polishing.