Leadon is located in blocks 9/14a and 9/14b in the North Sea, approximately 220 miles north-east of Aberdeen and 15 miles north of Kerr-McGee’s Gryphon development. The field was discovered in 1979 by the British National Oil Company, but it was considered sub-economic until an an appraisal well was drilled by Kerr-McGee in 1998. Using modern geophysical tools, this suggested that a northern extension would be oil bearing.

SATELLITE OIL FIELDS

The decision to develop the field was made in association with the development of two satellite fields: Birse stretching across blocks 9/14b, 9/14a; and Glassel in block 9/14a. These are located about 5 miles from Leadon. A number of acquisitions during 1998/99 resulted in Kerr-McGee gaining a 100 per cent stake in the development.

INVESTMENT

The Leadon development cost is projected at $600 million to $700 million, depending upon the size of the finished field size.

The field came on-stream in late 2001, less than two years after the field discovery and less than one year after government approval of the field’s development. It represents the largest net investment in Kerr-McGee history, as well as the largest development in the UK sector of the North Sea by any company in 2001.

PROJECTED OIL PRODUCTION

Combined reserves are estimated at 120 million to 170 million barrels of oil equivalent and the life of the field is put at over 16 years. The initial production rate was approximately 10,000bpd, and is expected to ramp up to peak production in excess of 45,000bpd.

SUBSEA HORIZONTAL WELLS

Because the Leadon, Birse and Glassel fields lie in a water depth of 370ft, they were developed using subsea horizontal wells tied back to a floating production, storage and offloading (FPSO) facility. The FPSO was christened as the Kerr-McGee Global Producer III.

DESIGN

The vessel is 712ft long and it can store up to 500,000 barrels of crude oil. On the topsides, facilities have been installed to process up to 300,000 barrels of gross fluids, 70,000 barrels of oil and 75 million ft³ of natural gas per day. The swivel stack for Leadon, supplied by Framo Engineering, is the largest ever built for an FPSO.

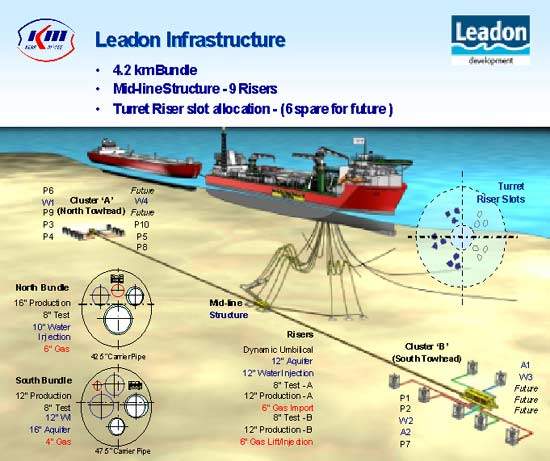

The field is produced from two clusters. Cluster A has seven production wells, two water injectors and space for a future well. Cluster B consists of three production wells, two water injectors, two aquifer wells and space for three future wells.

The Cluster A (North towhead) is linked to a mid-line point under the FPSO by a 16in production line, an 8in test line, a 10in water-injection line and a 6in gas line – all housed in a 42.5in carrier pipe.

Cluster B (South towhead) is linked by a 12in oil production line, a 12in test line, a 12in water-injection line, a 4in gas line and a 16in aquifer line – all housed in a 47.5in carrier pipe.

Oil will be stored on-board the FPSO and exported using a shuttle tanker. Produced gas will be used for fuel and any excess gas will be re-injected to assist production.

LEAD CONTRACTORS

Kerr-McGee acquired the Mitsui F-601 hull from Tokyo-based Mitsui Engineering. The topsides processing facilities were constructed by Swan Hunter on Tyneside. Halliburton – Brown & Root provided detailed engineering from Aberdeen. Rockwater were involved in the fabrication of the pipeline bundles at Wick, with Baker Hughes supplying the produced water package from the Midlands. Over 75 companies, spread throughout the UK, have also benefited from their involvement in this project. Inmarsat’s subsidiary Inset was awarded the upgrading and modification contract by the offshore operator Kerr-McGee, to provide an array of enhanced telecommunication services for the FPSO. DNV has been assigned to provide verification services in accordance with UK Legislation for the design, construction, hook-up and commissioning phases of the project.