The Perdido Regional Host development lies in the Gulf of Mexico, approximately 200 miles south of Freeport (Texas). It will be developed by a spar moored in 7,817ft (2,383m) of water, making it the deepest spar production facility in the world and the first with DVA (Direct Vertical Access).

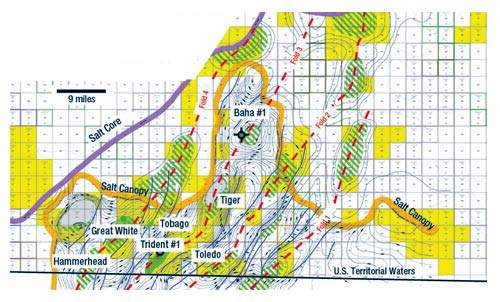

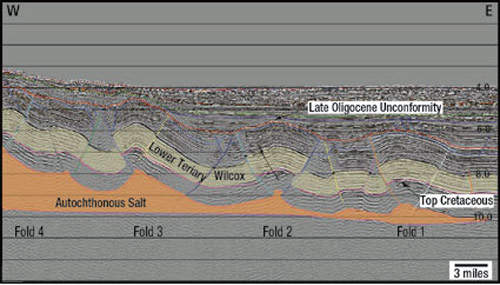

It lies in the Perdido Foldbelt, in the remote western Gulf of Mexico, approximately 200 miles south of Galveston. Perdido geologic conditions are different from areas that have previously produced hydrocarbons in the Gulf of Mexico and will be the first time for production from the Lower Tertiary (Paleogene) play.

PERDIDO OPERATORS

Shell operates the Perdido Regional Development (35%) on behalf of Chevron (37.5%) and BP (27.5%) and centres upon three fields:

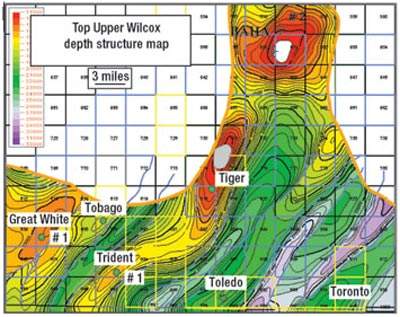

Great White (Shell 33.34%, Chevron 33.33% BP 33.33%) is among the first Lower Tertiary discoveries. Shell drilled five wells at Great White, the original well being drilled to a vertical depth of 14,405ft.

Tobago (Chevron 57.5 %, Shell 32.5% percent and Nexen 10 %) is located on Alaminos Canyon 859 in 9,600ft of water. The discovery well was drilled in 2004 to a total depth of 18,510ft. A sidetrack well was drilled to 18,425ft.

Silvertip, on Alaminos Canyon Block 815, (Chevron 60%, Shell 40%). Chevron drilled the AC 815 No. 1 discovery well in August 2004 in roughly 9,200ft of water to a total depth of 14,778ft.

REGIONAL DEVELOPMENT

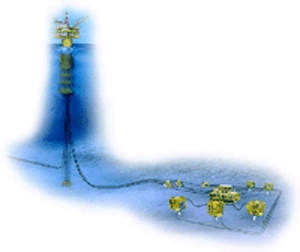

Shell’s concept for regional development includes a common processing hub in Alaminos Canyon Block 857 near the Great White discovery that incorporates drilling capability and functionality to gather, process and export production within a 30-mile radius of the facility.

This regional concept will also reduce the number and size of the facilities and operations in this challenging frontier area, resulting in a lower environmental impact than would otherwise be achieved. FMC Technologies will supply the subsea completion and subsea processing systems.

The scope of supply includes 17 subsea trees rated for 10,000psi, two subsea manifolds, five subsea caisson separation and boosting systems, topside and subsea controls and related subsea equipment.

PERDIDO CONTRACTORS

Shell awarded Technip a contract to provide the Engineering Procurement and Construction (EPC) of the spar hull and mooring system. Following the worst hurricane season on record in the Gulf of Mexico, the existing offshore spar production facilities proved their robust design, confirming the spar’s unique features and benefits even during extreme conditions.

The Perdido hull was designed by Technip Offshore built in Pori, Finland. The topsides were designed by Alliance Engineering and constructed by Kiewit Offshore in Corpus Christi.

This Technip contract covers the spar hull and mooring system design and fabrication, load out onto a transportation vessel, transportation and quayside delivery at a yard of the Gulf of Mexico. It also covers the design of the steel catenary risers, top tension risers and umbilicals.

Acergy North America won the transportation and installation contract for the subsea production umbilicals. Workscope comprises approximately 60km of steel-tubed super duplex subsea production umbilicals, four dynamic and three static, including associated flying leads and subsea hardware in up to 9,643FSW (2,940MSW). Acergy’s Acergy Eagle and Polar Queen are expected to be used for the project.

ABS are providing CVA Certification Verification Agent fabrication survey services in both Pori and Corpus Christi. Additionally, survey and validation services will be provided at the various facilities where major mooring components are being made.

First production from Perdido is expected around the turn of the decade, with the facility capable of handling 130,000bpd.