Roncador is a producing oil and gas field located in the Campos basin, off the coast of Brazil.

The field, which has been in production since 1999, is operated by Petrobras with a 75% interest. Equinor acquired the remaining 25% interest in the field from Petrobras in June 2018.

Roncador is currently Brazil’s fifth largest producing field and the second largest producing field outside the pre-salt layer.

It currently produces approximately 170,000 barrels of oil equivalent (boe) a day and nearly 30,000boe a day of associated gas. It is expected to have more than ten billion boe in place. The licence covering the field is valid until 2052.

Roncador Oil and Gas Field location and discovery

Roncador is situated 130km off the north-eastern coast of the state of Rio de Janeiro, Brazil. It is located at water depths ranging between 1,500m and 2,000m, north-east of the Albacora field and to the east of the Frade field in the ultradeep waters of the Campos basin.

The field was discovered in 1996 by the wildcat well RJS-436, which found reserves of 31° API oil in Cretaceous sandstone.

The second exploratory well, the 1- RJS 513, was drilled toward the southwest of the field in water depths of 1,559m in October 1997.

The well confirmed the extension of the reservoir but revealed the existence of an 18° API oil. It also discovered an unexpected gas cap in the reservoir.

Explosion at Roncador oil and gas field

In March 2001, the P-36, which was stationed over the Roncador field, sank after three explosions left 11 workers dead.

The P-36 was considered the world’s biggest semi-submersible at that time. It produced 84,000 barrels per day (bpd) and 1.3 million cubic metres of gas a day.

Petrobras said that there had been a gas leak, which escaped into the column where the blasts took place.

Water flooded the platform pontoons, causing it to list at a 25° angle. The platform then commenced to sink, despite 4,100t of nitrogen being pumped into the flooded compartments at a rate of 200l per hour, in an attempt to discharge approximately 15% of the estimated seven million litres of seawater.

A total of 21 support vessels and the semi-submersible platform Petrobras P-23 were on location to help during the operations.

Early production system

In order to maximise reservoir information and improve the economics of the project, Petrobras took the decision to develop Roncador with an early production system until the main facilities were completed.

Petrobras signed a four-year charter with Falcon Reading and Bates for the Seillean floating, production, storage, and offloading (FPSO) unit.

The vessel had a displacement of 79,600t and the capacity to produce and process up to 20,000 barrels of oil per day (bopd). It had a storage capacity of up to 48,672m³ of oil, equivalent to 306,000 barrels.

The Seillean FPSO, which arrived in Brazil in December 1998, was equipped with a flare, two cargo-handling cranes, a process plant inside the hull, a completion tower, and crew accommodation.

Roncador field development

A semi-submersible with a processing capacity of 180,000 barrels per day (bpd) was installed at a water depth of 1,360m in the first phase of the project.

The rig, the ex-Spirit of Columbus, was re-named Petrobras 36 and adapted for deepwater production at the Davie Yard, in Quebec, Canada.

The semi-submersible had a processing capacity of 180,000bpd, a compression capacity of 4.8 million m³ a day, and a water injection capacity of 24,000m³ a day.

The oil was transferred from Petrobras 36 to a very large crude carrier (VLCC) tanker, converted at AESA Shipyard in Cadiz, Spain.

The Petrobras 47 tanker functioned as a floating storage and offloading (FSO) unit.

Located at a water depth of 815m, the vessel had a deadweight of 268,000t, a storage capacity of 1.8 million barrels (bbl), and a liquid transfer rate of 3,250m³ an hour.

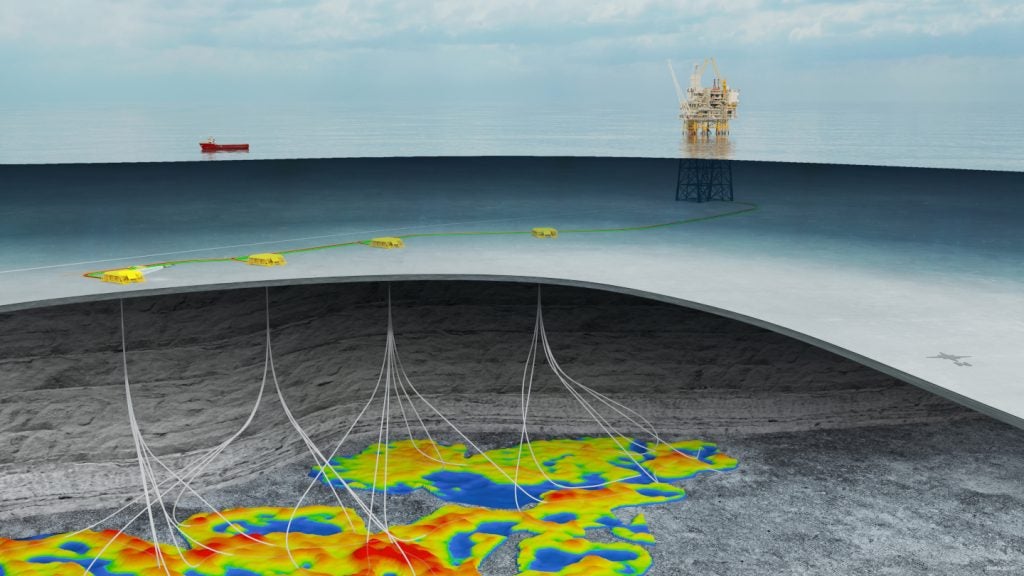

The oil came onstream by means of 26 wells, including 21 production wells, and five injection wells. Gas was exported through a 176km-long, 20in diameter pipeline. There were a total of 467km-long flowlines of 4in and 6in diameter.

After the accident, Petrobras took a series of measures to minimise oil production losses.

The company adopted two actions including the interconnection of new wells from the final design of Module 1 in the Marlim Sul field (platforms P-30 and P-38).

Two production systems, including platform P-52 and FPSO Brasil, were introduced to substitute the P-36. Production from platform P-52 started under Module 1A phase two in November 2007 while peak production was achieved in the second half of 2008.

Platforms and production details

Located at a water depth of 1,800m, the platform P-52 is connected to 18 producers and 11 water injector wells. Oil lifted by the well is sent to an autonomous re-pumping platform (PRA-1) and then transferred to an FPSO (FSO Cidade de Macaé) from where it is offloaded by ships to the São Sebastião terminal for domestic supply. Oil intended for export is dispatched through off-loading ships.

The produced gas is transferred to a distribution unit and then to the Garoupa platform from where it reaches the mainland.

The platform P-54, which is an FPSO developed by converting the Petrobras’ ship Barão de Mauá, started operations in December 2007. It was moored at a water depth of 1,400m and was connected to 17 wells, including 11 oil and gas production wells, and six water injection wells.

The unit has the capacity to produce 180,000bopd and can generate electricity, which is enough to supply 290,000 people.

P-55, which is a semi-submersible unit, was installed at a water depth of 1,800m under the Module 3 project. It has an oil production capacity of 180,000bpd, a gas compression capacity of six million metres cubed of natural gas, and a water injection capacity of 290,000bpd. The 52,000t unit commenced production in December 2013.

The semi-submersible platform is connected to 17 wells. The oil and gas from P-55 are exported through submarine pipelines.

The production from the P-62 FPSO platform under the Module 4 project started in May 2014. Located at a water depth of 1,600m, it is connected to 14 production wells, and eight water injection wells.

The oil from the P-62 is transferred through shuttle tankers while gas is transferred through a pipeline connecting to the gas distribution network of the Campos basin.

The unit has an oil production capacity of 180,000bpd and a gas compression capacity of six million metres cubed.

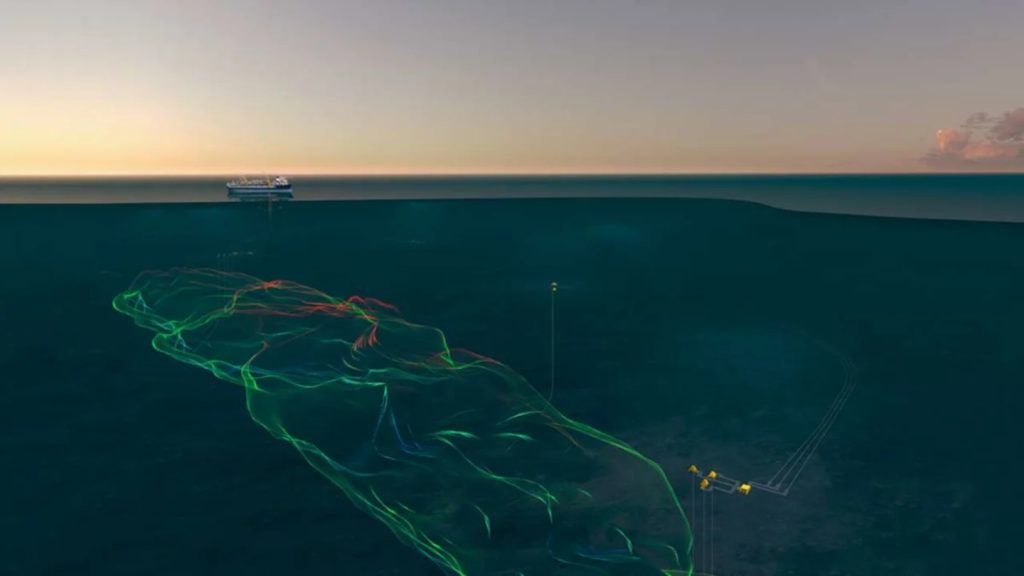

Increased oil recovery (IOR) project at Roncador

Equinor entered the project as part of a strategic agreement with Petrobras to expand collaboration and increase its foothold in the country.

The partners agreed to maximise the upside potential from the Roncador field to further increase its active life.

Petrobras and Equinor initially aimed to increase the recovery factor of the field by five percentage points to expand the remaining recoverable resources to more than 1.5 billion barrels of oil equivalent (boe) from one billion boe. They aim to further increase the recovery factor by ten percentage points to increase the total recoverable volumes by one billion boe.

The partnership leverages Equinor’s increased oil recovery (IOR) technology to extract more oil from the existing reservoirs.

The first two wells under the IOR project at the Roncador field were brought onstream in April 2022. The combined production capacity of the wells is approximately 20,000boe a day, increasing the field’s production capacity to 150,000bpd.

The IOR project involves the drilling of 18 wells including the first two currently under production. The 18 wells are expected to add 160 million barrels. The wells will have an improved design, which is expected to help reduce the carbon intensity of the field.

Contractors involved

Petrobras signed a contract with MODEC for the engineering, procurement, construction, installation, and commissioning of the PRA-1 FSO for the Roncador, Marlim Sul, and Marlim Leste fields in June 2005. The contract requires MODEC to lease and operate the FSO for 20 years. Another chartering contract was signed with MODEC for the FSO Cidade de Macae MV15 in 2007.

SOFEC, a MODEC group company, provided an external turret mooring system for the PRA-1 platform.

Gas compression modules of the P-54 FPSO were provided by the Dresser Rand/Mauá Jurong consortium while the power generation modules were built by Nuovo Pignone.

Jurong Shipyard received a contract for the conversion of the P-54 platform. The contractual scope included hull conversion, manufacturing process and utility modules, and integration of the final platform.

Technip (now known as TechnipFMC), in partnership with Subsea 7, was contracted to provide engineering, procurement, installation, and construction services for the Roncador field development in March 2005.

The scope of the $500m contract included the design, manufacture, and installation of flexible risers and flowlines, as well as the installation of umbilicals and jumpers for the tie-back of production and injection wells to the P-52 unit.

Aker Solutions received two contracts to supply subsea connection systems for the P-55 production platform in November 2009.

Wartsila Technology’s Hamworthy business was engaged to supply a flare gas recovery system for the P-62 unit in August 2011.

Equinor signed a contract with Knutsen NYK Offshore Tankers to avail two shuttle tankers to carry crude oil from the field in 2018.

PGS was appointed in December 2021 to start a 4D acquisition survey over the Roncador and Albacora Leste fields in the second quarter 2022. The acquisition survey is expected to be completed in the third quarter of 2022.

GE received a contract to supply gas turbine and compressor equipment for deployment in the FPSO P-62 for power generation and compression in July 2010.