Plastic energy chains, bearings and highly flexible cables by igus® UK are used widely in offshore applications all over the world. Providing bearing and ATEX-certified cable management solutions, including pre-harnessing and drive cables, our portfolio of standard and bespoke systems is chosen for its long lifetime and maintenance-free capabilities. With more than 40 years’ experience in plastics and offshore components, igus produces high-performance plastic products that are suitable for almost any environment, whether that be heat, cold, corrosion, humidity or dirt.

Benefits of the igus energy chain

Nowadays, traditional steel bearings and cable management systems that are adverse to corrosion, wear, sea water and the harsh offshore environment are successfully replaced with plastic energy chains because of their extraordinary capabilities. For instance, festoons are often replaced with plastic energy chain systems that guarantee a much smoother operation and longer performance expectancy. The reason for switching to igus plastic parts is simple as they are oil-resistant, corrosion-free and lightweight yet highly stable. igus plastic is lubrication-free, which eliminates timely unscheduled maintenance.

ATEX-certified drag chain

igus’ plastic energy / drag chains are strong, modular in design and they facilitate very heavy fill weights. Installation is very simple, and additional accessories including troughs and mounting brackets allow plastic energy chains to be installed in a variety of orientations and long lengths of travel. All standard e-chains from igus are available in ATEX-certified versions. The material igumid ESD is explosion protective and as with all igus products, has been tested for millions of cycles within the igus laboratory and in real life applications.

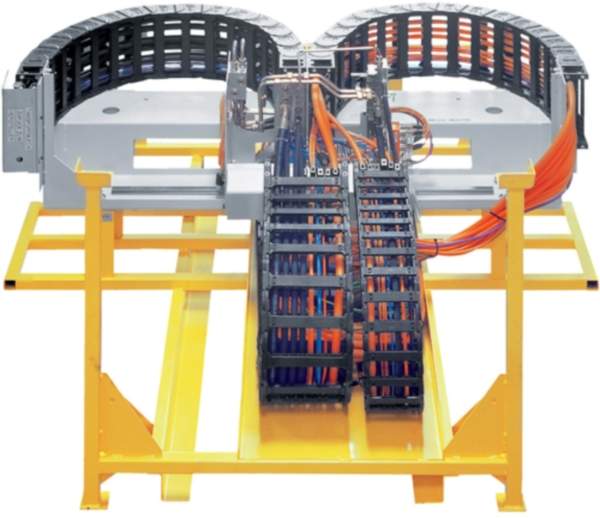

The world’s largest offshore cable chain

The rugged E4.350 offshore cable chain is designed to carry thick, heavy and stiff cables and hoses. Its oil-resistant feature makes it ideal for use on oil platforms in steel plants or in heavy-duty machinery. This quiet cable management system can manage heavy fill weights of up to 600kg per metre. It is totally lubrication free, therefore doesn’t require any maintenance. Due to the modular nature of igus’ e-chains, the E4.350 can be lengthened or shortened to suit. If required, interior cable and hose separators can be supplied.

chainflex highly flexible cables

Reliable dynamic cables for use in energy chains in the offshore industry must not only be able to withstand harsh environmental elements but also the dynamics of moving applications. igus’ chainflex range of cables are designed to cope with these demands, and we have more than 950 different types in stock for selection. Their internal wire elements are bundled with shorter pitch lengths around the centre core rather than in layers and a highly abrasion-resistant, gusset-filled inner and outer jacket are used, eliminating any fraying and breakages to the copper wires.

In some chainflex cable types, further protection is offered by incorporating a shield with optimised braiding angle around the extruded inner jacket to provide torsion protection and prevent any internal and external interference, which normally occurs in dynamic applications during the constant bending process.

Ready to install pre-harnessed energy chains and cables

igus understands how time-consuming harnessing cables can be in large cable management systems and, as a result, offers a pre-harnessed solution that can be ready to install directly to your machine in as little as three to ten working days. By using the readychain® service assembly, turnaround time is reduced by 50%, storage costs for cables, connectors and energy chains is eliminated and everything can be ordered and supplied by one single source.

100% lubrication-free plastic bearings

igus offers a comprehensive range of heavy-duty plain bearings, slewing rings and linear bearing systems that do not require any grease and eliminate maintenance downtime. These products are suitable for use in areas that are under extreme mechanical stress and subject to aggressive media. Again, all bearing products from igus are modular and easy to install and come with the igus lifetime guarantee. For further information on our products and services please contact us through the details provided below.