SPRIANO® engineers and manufactures pneumatic and electronic instruments for automation and control, which can be system-integrated into turnkey systems for various industrial sectors, such as chemical, oil and gas, pharmaceutical, food, power and naval. ISO9001, ATEX and PED certifications guarantee the products to be compliant with the up-to-date technical standards. Our consolidated activity in Italy is integrated by a growing export activity in many foreign countries, managed by an internationally selected and well-trained sales network.

SPRIANO products are available in standard (carbon steel, low temperature carbon steel, 316 and 321 stainless-steel) and special alloys (Hastelloy C, duplex, titanium, Inconel), all compliant to NACE latest requirements. The product range includes pressure, differential pressure, and level and temperature electronic transmitters.

Depending on the application, SPRIANO can offer instruments approved for intrinsic safety areas or with explosion-proof protection. The output signal of the transmitter is 4mA – 20mA with HART communication protocol, Profibus or Fieldbus foundation.

Torque tube level transmitters

SST50 (exia) and SST70 (exd) series SMART level transmitters are microprocessor-based instruments that combine the analogue signal advantages (4mA-20mA) with the flexibility of digital communication (HART®, FF, PA) protocol.

The transmitter series SST70 measures liquid levels, density and interface levels in closed or open vessels. It converts buoyant force exerted by a displacer immersed in a liquid to a proportional current signal, thanks to a mechanical forces transmission device based on a torque tube and a piezoresistive sensor.

Temperature transmitters

SST52 (Exia) and SST72 (Exd) series SMART temperature transmitters are able to accept three wires and Pt 100 ohm resistance thermometers, with total accuracy dependent on class of the sensors utilised such as DIN A, DIN B, 1/4 DIN, 1/10 DIN.

Based on these readings the microprocessor generates the 4mA – 20mA analogue output two-wire system and displays the pressure measurement on the LCD. Some of the main characteristics of this microprocessor-based transmitter are:

- Wide rangeability

- Automatic temperature compensation

- Digital communication using HART®, PA or FF protocol

Differential pressure transmitters

SST57B (Exia) and SST7TB (Exd) series SMART differential pressure transmitters can be remotely configured by a universal hand-held terminal (HHT) or by a PC with a dedicated interface and SPRIANO software. Moreover, it is possible to locally configure the instruments (zero and span) by means of two push buttons, and to display the data on the wide LCD display. The SST57B transmitters measure differential pressure with spans from 1,125mbar to 20,000mbar with a static pressure up to 100bar. Thermal drift is compensated using the temperature signal generated by a PTC thermistor integrated in the sensor itself.

Current-to-pressure converters

SEX71A current-to-pressure converters are based on a force balanced system with electronic feedback; by measuring the output signal with a piezoelectric sensor, and computing it with dedicated SMT electronics, a reliable and high-performing instrument is obtained.

An extraordinary accuracy less than 0.25% (comprehensive of non-linearity, hysteresis and repeatability errors) is reached by this converter, four times better than what’s typically found on the market. The converter is provided with intrinsic safety approval.

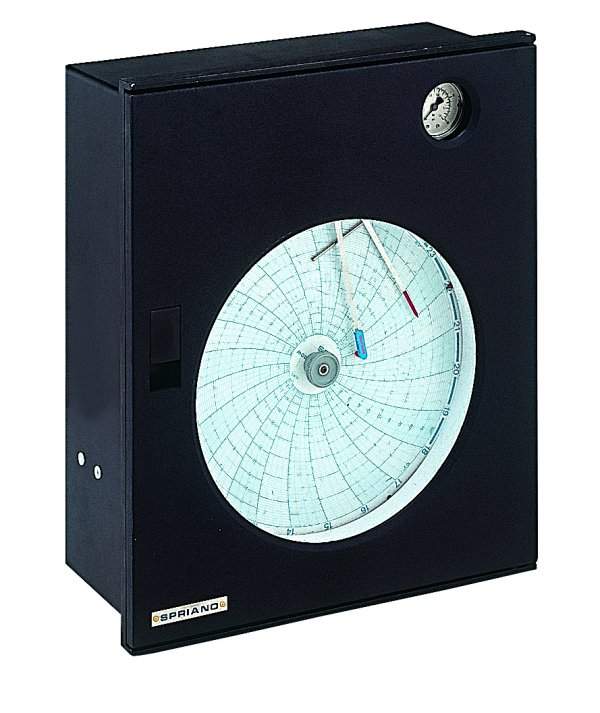

Pneumatic indicating controllers, regulators and recorders

Ideal for the control of temperature, pressure and level in industrial or process plants, as the indicating controller is used for control of liquid, gaseous or vaporous media. The instrument senses the temperature, pressure or level of the measured medium directly, displays the operating value, compares the measured variable with the set point and puts out a pneumatic standard signal of 0.2bar to 1bar or 3psi to 15psi.

This output pressure actuates final control element, the pneumatic valve. Four control forms are available: on-off, proportional, integral and derivative. The units could be also used for remote control of process operations as pneumatic transmitter (output 0.2÷1bar or 3psi÷15psi) or receiver controller (input 0.2bar÷1bar, 3psi÷15psi).