Crude Distillation Unit Column Overhead Corrosion Protection

Repair and outage costs of refinery Crude Distillation Units (CDUs) can be significant, involving the complexity of shell replacement or weld overlay and associated PWHT.

Based in Virginia, US, Integrated Global Services, Inc. (IGS) offers surface protection solutions to clients on a global scale.

You have successfully submitted your enquiry. Someone from our company will respond ASAP

Integrated Global Services, Inc. (IGS) is an international turnkey provider of efficiency and reliability surface protection solutions.

Boasting over three and a half decades of expertise, IGS has become a trusted partner to international plants, assisting them in addressing issues of metal wastage and reliability in mission-critical equipment.

IGS consists of operational hubs, subsidiaries, and sales offices globally to address the needs of global refining facilities. IGS is one of the top industry leaders in developing solutions to erosion and corrosion issues in difficult operational conditions.

IGS offers a variety of solutions that include:

High Velocity Thermal Spray (HVTS)

HVTS is a proprietary coating system designed to address corrosion and erosion problems in process vessels, towers, and columns. It is a time and cost-effective and reliable solution that extends equipment life.

Cetek Ceramic Coatings

Cetek Ceramic Coatings offers a versatile, durable, protective thin-film layer on the outer parts of tubes for the effective prevention of metal oxidation, corrosion, and carburisation and helps preserve the tube thermal conductivity coefficient close to new tube conditions.

Cetek ceramic coatings have been applied to more than 200 refining facilities globally, minimise fuel consumption, lower emissions, and boost production by enhancing fired heater radiant section efficiency.

Tube Tech Fouling Removal

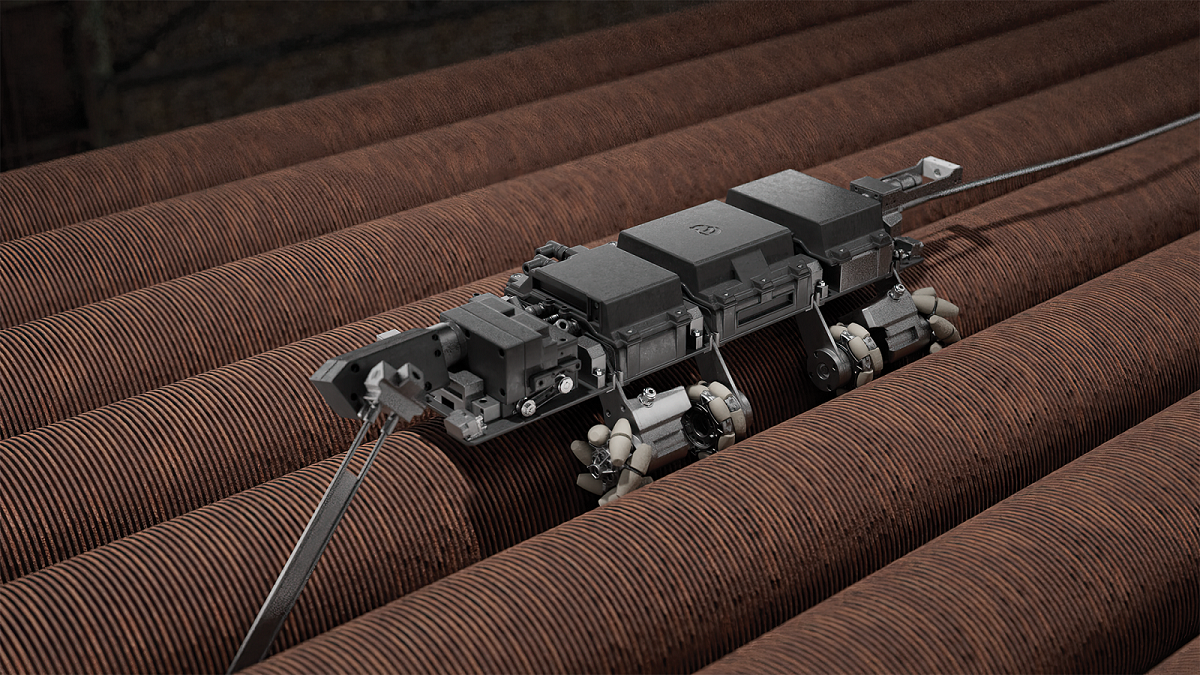

Tube Tech is popular due to its ability to solve the greatest fouling challenges worldwide. Tube Tech utilises its own technologies, including robotic systems, to remove over 90% of fouling from fired heater convection sections, heat exchanger bundles, Texas Towers (VCFEs), and a variety of other mission-critical assets.

By restoring heat transfer efficiency of the convection section, Tube Tech used in conjunction with Cetek ceramic coatings, Tube Tech can restore convection section heat transfer efficiency and can greatly enhance fired heater capacity, as well as lower CO2 and fuel consumption by up to 15% and reduce NOx emissions by up to 30%.

Hot-Tek

Hot-tek offers essential maintenance during normal operation (between turnarounds) to avoid unplanned shutdowns. These services consist of:

IGS is a specialist in global on-site technologies and exhibits a wide range of shop production capabilities. Its Technology Research Center helps the world’s leading refining facilities resolve their most critical surface engineering-related challenges, develop coating and welding techniques even further, and measure material performance.

With the largest global presence in the industry, IGS has the operational capacity and experience to provide solutions on-site across six different continents.

Integrated Global Services, Inc. (IGS) is an international turnkey provider of efficiency and reliability solutions.

Our proprietary High-Velocity Thermal Spray (HVTS) coating systems solve corrosion and erosion problems in process vessels, towers and columns.

IGS utilises a variety of services for the improvement of fired heater efficiency when it comes to delivering increased capacity, up to 15% CO2/fuel reduction, and 30% less NOx. Cetek ceramic coatings boost radiant efficiency and increase throughput in fired heaters. Tube Tech services achieve a 90%-clean convection section while Environmental solutions enhance SCR efficiency and eliminate downtime.

IGS has one of the largest global footprints in the offshore industry, with operational capabilities and experience delivering solutions on-site on six continents.

Repair and outage costs of refinery Crude Distillation Units (CDUs) can be significant, involving the complexity of shell replacement or weld overlay and associated PWHT.

When faced with metal wastage, asset owners and operators have viable options available to them in addressing the corrosion mechanisms with a CRA barrier.

Many oil and gas companies are repurposing refineries to produce renewable diesel, sustainable aviation fuel, and other renewable biofuels and products.

All process heaters operate at high temperatures and are constructed with process tubes inside a refractory-lined enclosure, which is heated by radiant heat from gas-firing or, less commonly, oil-firing.

Sulfolane unit separates aromatics from non-aromatics in a hydrocarbon mixture. Sulfolane is a cyclic sulfone that has high solubility and selectivity for aromatics.

A large oil refinery in Texas required a solution to corrosion that had taken place within three of its sulfuric acid alkylation unit (SAAU) reactors caused by a high concentration of sulfuric acid.

This energy company in Malaysia operates various facilities across the country, including a chemical ammonia plant, located on the East Coast of Malaysia.

A multinational investment company and an American energy corporation have embarked on constructing a groundbreaking direct air capture facility in Texas, the US.

During our recent webinar (if you missed it live, you can still watch it here on demand), Johnny Smatana reviewed a case study (read it here) where we repaired internal refractory on a live SMR.

All process heaters operate at high temperatures and are constructed with process tubes inside a refractory-lined enclosure, which is heated by radiant heat from gas-firing or, less commonly, oil-firing.

IGS Corrosion Mitigation SME is answering frequently asked questions about HT/HP process vessel corrosion.

The report outlines the company’s ESG commitments and the environmental and social impact.

High-Velocity Thermal Spray (HVTS) cladding technology has a well-documented history of shell protection in sour conditions where low, or locally low, pH results in material wastage.

Rich Crawford, CEO and president of Integrated Global Services (IGS), is confident in the company's growth prospects.

Integrated Global Services (IGS) has been recognized as a major contributor to the successful Ras Tanura Refinery (RTR) 2024 Mega Turnaround and Inspection (T&I) for Saudi Arabian Energy Company (Aramco).

In the world of industrial applications, where precision and innovation meet the demands of modern manufacturing, one challenge stands as a formidable obstacle—hexavalent chromium exposure.

IGS Tube Tech has won an International Safety Award from the British Safety Council in recognition of its commitment to keeping its workers and workplaces healthy and safe during the 2023 calendar year.

Integrated Global Services, Inc. (IGS) has been named a 2023 Supplier Award winner by ADM (NYSE: ADM), a global leader in sustainability-sourced solutions from nature.

We are pleased to announce the launch of our podcast, “Efficiency and Reliability”.

Steam Crackers play a crucial role in various industries, ensuring the efficient production of ethylene and propylene.

Tube Tech, a leader in premium cleaning and inspection solutions for oil and gas, petrochemical and agrochemical plants, has launched its next-generation Mark 7 fired heater rover system.