Combifloat products that we supply have been developed in close cooperation with the industry because of the growing need for economical and practical solutions to tackle marine challenges.

This need called for a solution by means of a standardised modular equipment system for versatile applications and operations in coastal and inland waters.

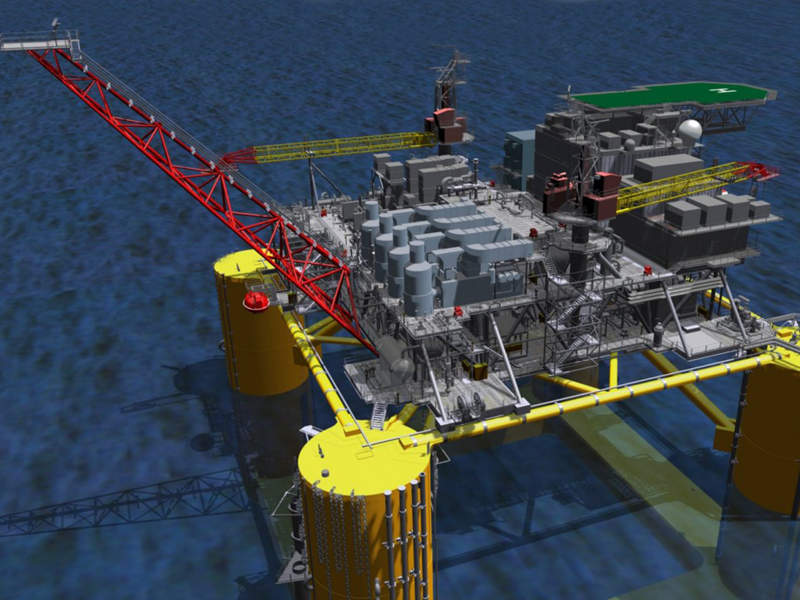

Typical applications for our floating modular construction system are:

- Self-elevating platforms of up to approx 1,000mt payload

- Accommodation platforms

- Oil and gas drilling barges

- Lay barges

- Transport barges

- Ferries

- Bridges

- Jetties

- Hoover platforms

- Crane pontoons

- Exhibition platforms

- Work / push boats etc.

Our equipment is strong, simple to use and built with precision, allowing the equipment to bear deckloads and withstand forces beyond that of any other portable flotation equipment available to the industry.

The Combifloat pontoons are standardised, precision-built, watertight steel pontoons, based on a high-strength internal structure and external coupling mechanism, for connecting with other pontoons in project-specific configurations, with adequate strength and stability characteristics for supporting heavy deckloads and different types of equipment needed for the execution of the project.

All Combifloat pontoons are already internally strengthened for use in self-elevated platforms.

Transporting and handling Combifloat pontoons

The Combifloat pontoons have dimensions that allow easy transport and have unit weights that can easily be handled by available jobsite lifting equipment. The pontoons are free of protrusions that may hinder stacking or sliding of one unit over another. Each unit has an integrated lifting lug at its balance centre and easily accessible openings for ropes needed for launching, mooring or assembling. All equipment is designed and dimensioned for easy handling, easy transportation, use at diverse and remote locations and assembly by inexperienced personnel.

The Combifloat pontoons and equipment may be locked together side-to-side, offset, end-to-end and end-to-side, to form an infinite number of configurations to support and stabilise all types of loads, without overstressing or distorting the structural system. The box girder structure of each pontoon is linked with an internal structure of longitudinal and transverse trusses connecting the locking units on opposite ends and sides. The structure is designed to flex under concentrated and combined bearing, tension, compression and torsional loads and distribute these stresses throughout the unit, to prevent permanent distortion under the abuses of abnormal and unusual load conditions. The design and manufacturing process and control, together with precision spacing of the male and female locking units, assures complete interchangeability of all units and easy assembly under field conditions.

Easy assembly and extreme durability

All Combifloat pontoons within each model series have equal drafts. Assembly of pontoons can be accomplished by an inexperienced crew of two men, quickly and with no tools other than a hammer, a pry bar and short sections of rope. All mating female couplings are opened with a crow bar, the floats are pulled into alignment using ropes threaded through elbows mounted at intervals on each pontoon, the couplings are mated until upper and lower parts are in near contact and the locking bar is driven down with the hammer until seated. The locking bar performs a wedging action to pull the pontoons into the final mating position.

Combifloat pontoons and equipment have been proven to have a lifetime of more than twenty-five years and both the pontoons and equipment require little or no maintenance.

Second-hand pontoons are difficult to find because, not only are the pontoons extremely durable, they are also reusable in the sense that each unit of the same series can be connected to any other of our pontoons or attachments in the same series, to form an endless number of configurations for a variety of functions. These advantages lead contractors to retain their equipment for many years. As a result, the equipment maintains its value and second-hand pontoons are hard to find.

Dependable engineering solutions

Combifloat has been very successful for more than fifty years, in meeting the needs of clients facing marine challenges. Our long history and extensive experience have contributed to our reputation for dependable engineering, sound workmanship and reliable service.

Combifloat will be pleased to assist you, free of charge, in finding the right solution for your marine challenges and, after careful evaluation, propose tailor-made solutions for your consideration.