Lödige offers a complete range of mixers, coaters, granulators, dryers, reactor systems, Ploughshare® Mixers, mixing technology, processing technology, mixing and fluidisation processes, mixed products and processing systems.

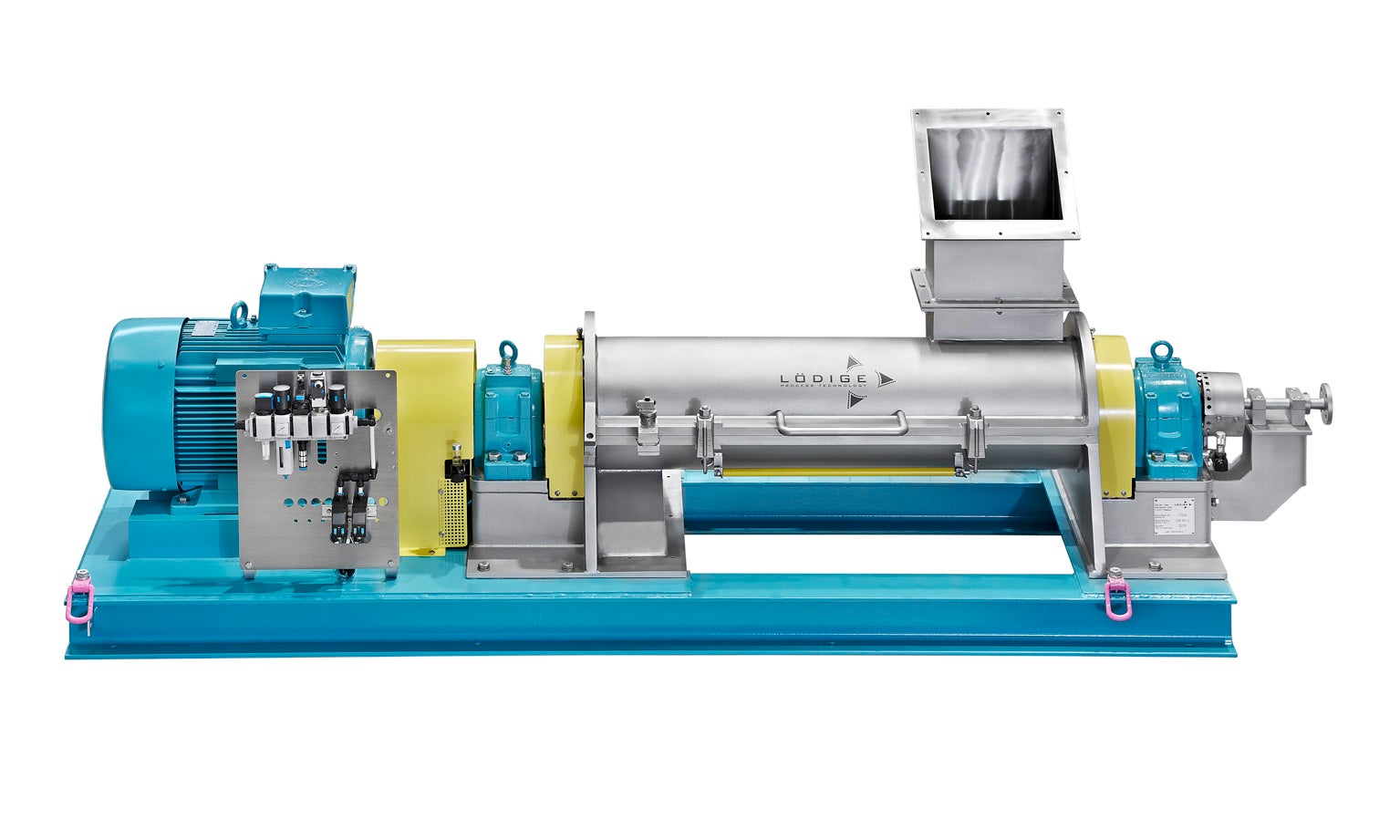

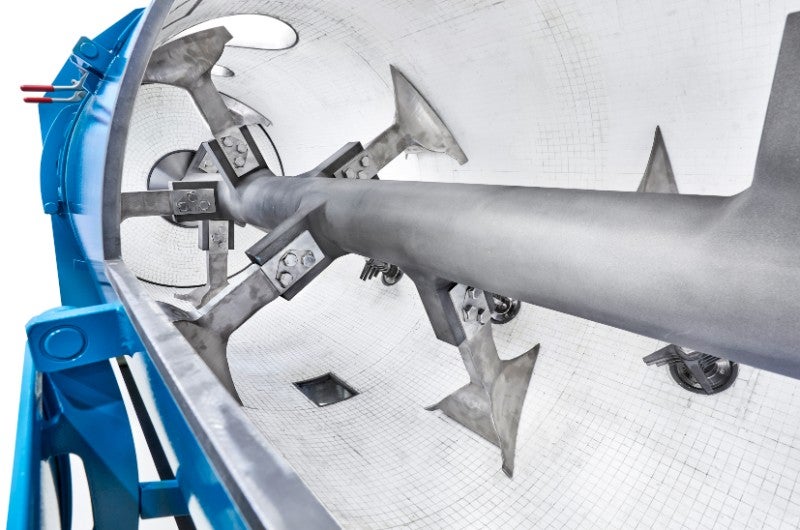

With the invention of the Ploughshare® Mixer, Lödige created a mixing unit that can handle a wide range of different processing tasks.

The company has a wide and international customer base, consisting of companies from the chemical, pharmaceutical, food and cosmetics industries, as well as building materials and plastics, metallurgy, cellulose, starch, minerals/ores and the environment.

Over 500 patents and more than 35,000 machines and systems attest to Lödige’s experience in providing customer-oriented system solutions.

Solution and service provider for all processes

Our customers appreciate the high quality of the mixed products, together with the speed and efficiency of the machines. In addition, mixers can be individually tailored to individual requirements of the respective industries.

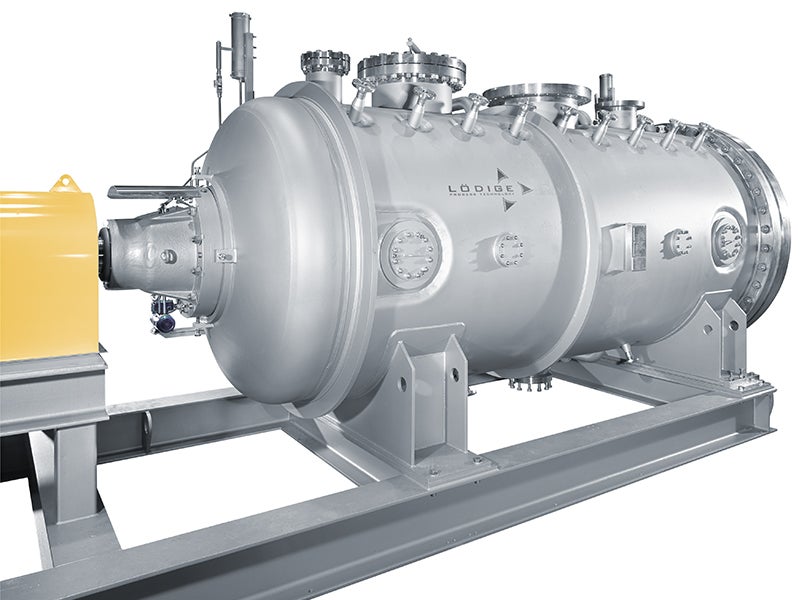

As a solution and service provider for all processes, Lödige delivers sophisticated operational sub-systems, and adapts them to the customer-specific processes and needs. As a one-stop solution provider, the company also offers turnkey installations. Lödige assumes all work stages from set-up to installation and commissioning of the turnkey solution.

In addition to focusing on core industries, closeness to the customer is for Lödige the key to sustainable corporate development. In addition to the individual application-specific design of each machine, this requires reliable customer service by experienced engineers, ranging from the installation, upgrades and modernisation to the dismantling and disposal of the system. This also includes emergency support in the unlikely case of a breakdown.

In-depth processing know-how for the chemical industry

Lödige sees itself as a reliable partner to the chemical industry. Its experts assist customers in finding solutions for converting the results of their development process to a production standard for various applications and implementing this standard through process engineering. Hence, their products can be produced and reproduced economically while ensuring high quality.

Lödige is also a partner for planning extensive equipment concepts, from support, planning and production of assembly groups to the design of turnkey systems.

Process engineering solutions for chemistry applications

Process engineering tasks in the chemical industry are highly diverse. Lödige solutions are used for the following main processes:

- Mechanical processing of products

- Mechanical and thermal treatment of products

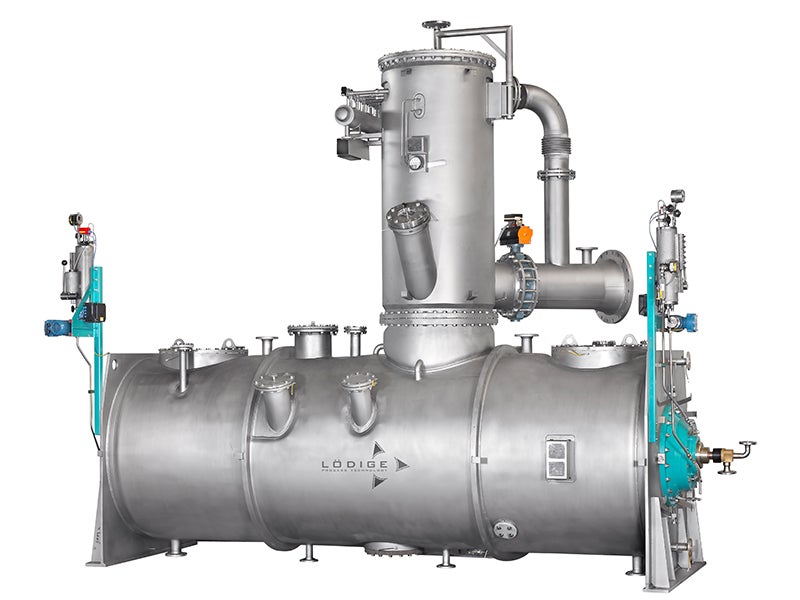

It is possible to complete multiple process steps in just one Lödige machine. This is called the ‘all-in-one process’. Often, the Lödige machine is used within a production line, where it can perform several different process steps and completely different recipes in a reproducible manner. This is due to the adapted control system.

When customers approach us with an application, we verify its feasibility and develop and fine-tune it at our in-house test centre through realistic production trials. After completing and evaluating these trials, we are able to design a suitable, optimised machine and advise our customer with regard to purposeful process control.

All systems listed below are available for production scale and in sizes suitable for laboratory work:

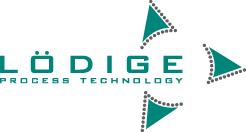

- Batch mixing and granulating in a horizontal system

- Continuous mixing and granulating in a horizontal system

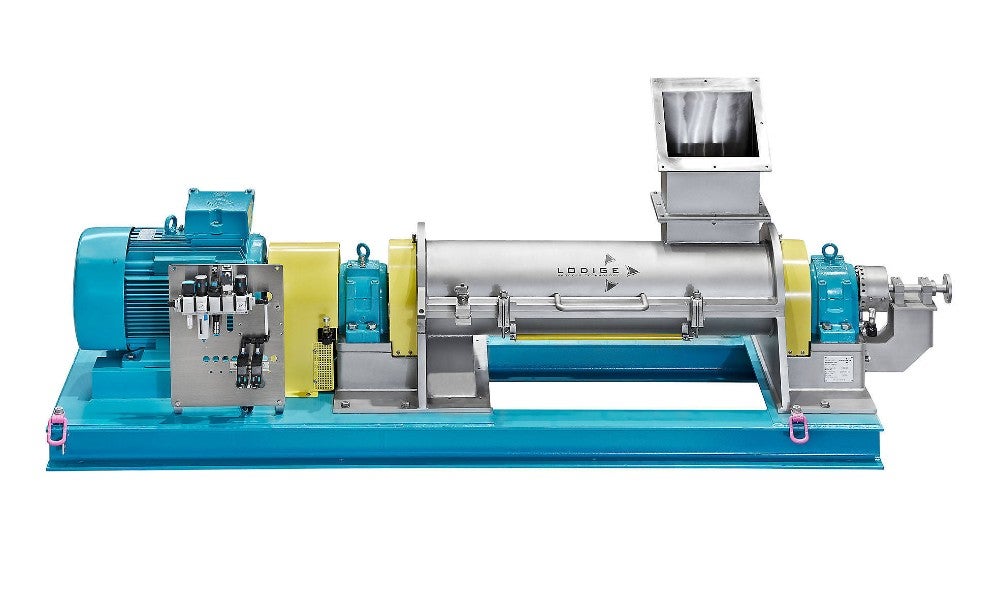

- Mixing and processing in a continuous ring layer mixer

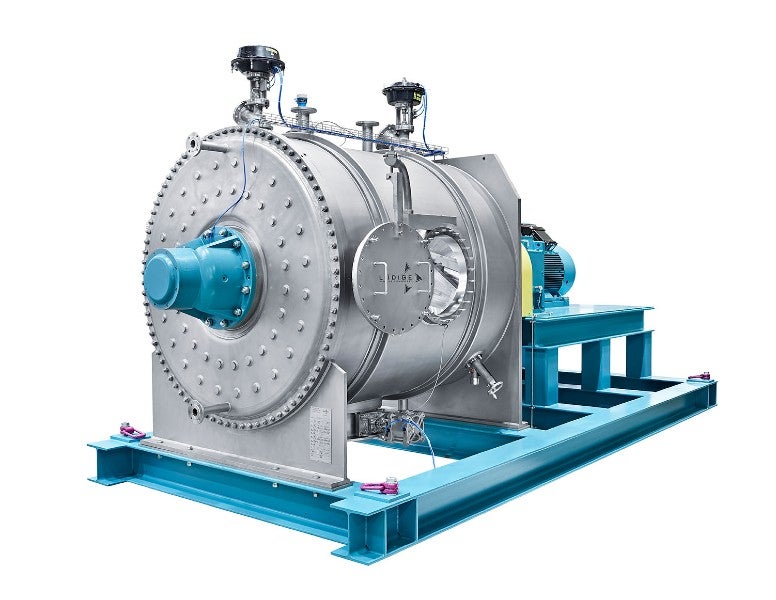

- Drying and mixing in a vacuum shovel dryer

About Lödige

Lödige operates with more than 500 employees worldwide, and supports its customers with a global network of subsidiaries, technical offices and agencies.

We have a subsidiary coordinating our North American business in Florence, Kentucky, US, as well as further subsidiaries in Spain and France. Joint ventures have been established in India and China. Additional licensees located in Brazil and Japan plus our worldwide representatives complete Lödige’s network.