Quest Integrity Group provides a unique solution to offshore pipeline inspection challenges such as low flow or low pressure lines, vertical risers, vertical launches, reduced space for traps, and limited launcher or receiver facilities.

The company’s proprietary ultrasonic (UT) inspection technology, InVista™, allows operators to overcome these difficult or challenging environments with its unique navigational capabilities and high collapse factor. The InVista tool provides complete wall loss and geometry pipeline data in a single pass and a high-level fitness-for-service assessment is included in the standard pipeline inspection deliverable.

In-line pipeline inspection

The InVista in-line inspection tool is lightweight, compact and easily transported by helicopter to offshore platforms. The tool can be launched by hand and is suitable for vertical launches. It is bi-directional, which aids the ease of access and reduces the space needed for traps. Since existing pigging facilities are used, little to no line modification or front-end engineering is required. All of these logistical efficiencies greatly reduce HSE concerns and manpower requirements.

The tool is designed to successfully inspect and perform in difficult environments. Because of a high collapsibility factor, InVista easily navigates short radius back-to-back bends, unbarred off-takes and pipe schedule changes, including heavy wall. The tool negotiates flexible risers and flex pipe and can perform in low flow and low pressure lines.

Capabilities:

- Provides 100% overlapping coverage of pipeline geometry and pipeline metal-loss features in a single pass

- Inspects 3in to 24in diameter and dual-diameter pipelines

- Navigates back-to-back bends with more than 90° short radius turns

- Navigates bore restrictions, step changes and reduced port valves

- Accommodates limited or missing launcher / receiver facilities

- Functions in no-flow or limited flow conditions

- Inspects non-standard and bulging pipe material

- Identifies significant wall thickness changes and wall loss

- Accommodates single entry / exit, line stoppage, plugged valves

- Traverses bottom unbarred tees, wyes and mitre bends

Advanced engineering assessment

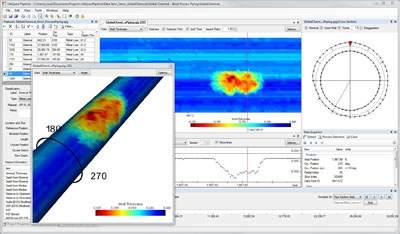

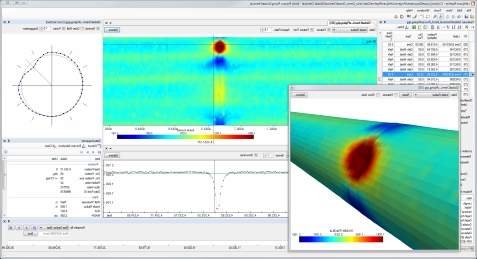

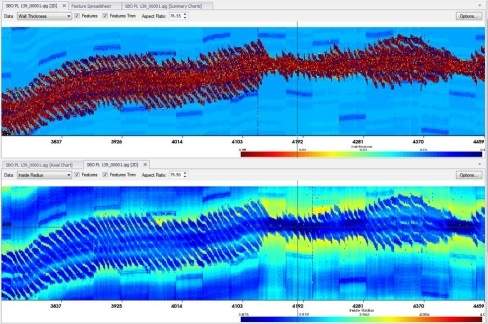

The company’s experienced data analysts and assessment engineers review and analyse 100% of the data collected by InVista using the company’s proprietary LifeQuest™ Pipeline software. They provide a Level 2 API fitness-for-service assessment as part of the standard deliverable. This allows pipeline operators to better understand, prioritise, schedule and extend maintenance intervals based on confidence in the data quality and integrated engineering assessment.

LifeQuest Pipeline:

- Utilises and displays 100% of the data provided by InVista

- Offers high-resolution 2D and 3D views of wall thickness and inner profile

- Provides fitness-for-service assessments in accordance with API 579 / ASME FFS-1

- Provides intuitive graphical presentation to enhance understanding throughout field ranks of anomalies and corrective actions

Advanced engineering assessment services include:

- Experienced assessment engineers

- Remaining strength and maximum allowable operating pressure for the entire pipeline

- Full API 579-1 / ASME FFS -1 Level 2 fitness-for-service assessments

- Run comparison and corrosion growth rate modelling

Quest Intengrity Group company profile

Quest Integrity Group is a global leader in the development and delivery of asset integrity and reliability management solutions for companies in the pipeline, refining and chemical, syngas and power industries. Services consist of advanced inspection and engineering assessment, and products that reduce operational and safety risk, improve operational planning and increase profitability.

Quest Integrity Group provides an innovative solution to overcome offshore pipeline inspection challenges and delivers a high-level fitness-for-service assessment within 30 days.