World-leading manufacturer and distributor of precision tubes for critical applications Fine Tubes is delighted to announce that it has been awarded a major order by FMC Technologies for the supply of advanced tubing for Total’s offshore Egina project.

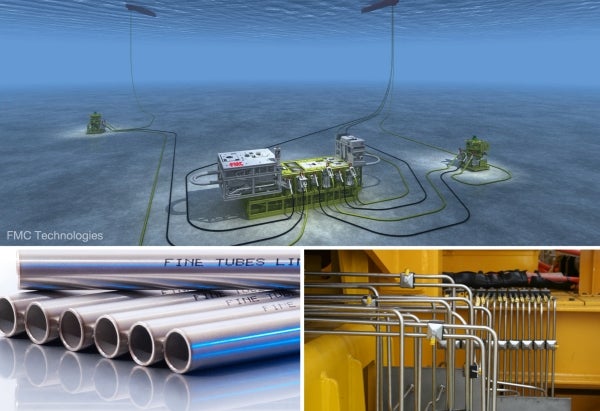

Located some 150km off the coast of Nigeria at a depth of up to 1,750m, the Egina oil field is being developed by Total Upstream Nigeria Limited for whom FMC Technologies is providing all the subsea production systems. The oil field is estimated to reach a peak production rate of 150,000 barrels per day and covers an area of around 500 square miles. Fine Tubes has been contracted to supply FMC with significant volumes of seamless instrumentation tubing for the control, hydraulic and injection lines required for the subsea manifolds.

Fine Tubes sales and marketing director Brian Mercer said: "Winning this contract is an important achievement for Fine Tubes, given the environmental and operational demands that will be placed on the tubing. It’s further evidence of our expertise in working with the most advanced materials to meet the most stringent quality and safety standards."

Fine Tubes has been delivering high precision tubes for super critical applications in the Oil and Gas industry for the last 70 years. The tube mill regularly supplies precision tubing in stainless steels 904L (UNS N08904) and 6Moly (UNS S31254), as well as nickel alloy 625 (UNS N06625) and alloy 825 (UNS N08825) for global offshore and onshore projects.

Fine Tubes oil and gas business development manager Ryan Dover said: "The subsea production systems deployed within the corrosive environment of the Egina oil field demand specialist corrosion resistant tubing. This is where our expertise lies with our extensive range of high performance alloys that offer extended product service life in the most hostile offshore conditions."