Frictape is world’s largest manufacturer of helideck safety nets with more than 1,300 installations globally, serving the offshore industry, as well as onshore helipads and megayachts.

Landing and perimeter safety nets for offshore and onshore applications

The company’s landing and perimeter safety nets are manufactured from in-house developed, highly engineered semi-synthetic tape, which offers several benefits in harsh offshore environments.

Ultra-durable landing and perimeter safety nets secure helidecks on offshore structures and seagoing vessels, preventing helicopters from sliding and personnel from falling overboard. Frictape is the only safety netting company in the world holding both ABS and DNV approvals.

With Circle & H Netlight, Frictape has extended its product range to helideck lighting. With Netlight, no fixed light structures are required, as no holes need to be drilled as light modules are integrated with the landing net, delivering several benefits in terms of cost and effort compared with traditional lighting solutions.

Synthetic materials for safe and strong helideck nettings

The unique material used in Frictape nets outperforms traditional rope and steel mesh structures, providing an optimal combination of strength, durability and lightness. Frictape helideck nettings feature a completely balanced zero-deformation, zero-bounce structure for increased safety.

Frictape landing nets provide higher friction than traditional rope nettings, and will not deform or distort regardless of the weather. As the net always stays in its form, there is no need for constant tightening and loosening. A low-profile knotless structure increases safety and convenience of walking and enables the use of wheeled carriages.

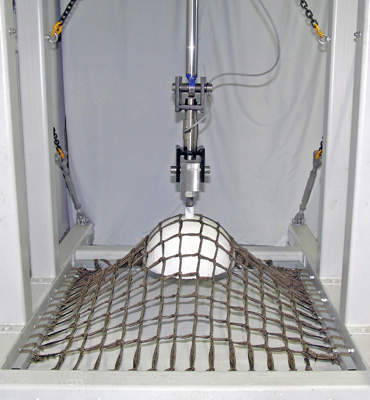

Frictape perimeter safety nets far exceed the strength required by industry standards. Custom-made for exact fit, Frictape nets are directly attached to the helideck structure with fail-safe braiding using the same material, resulting in completely balanced structure with no weak points. Frictape nets produce a hammock effect, absorbing the kinetic energy of falling objects or persons and recovering to their original form after tension.

While ropes only last for one to two years, the best synthetic materials meet their specifications for five to ten years. As longer lifetime translates into fewer installation projects, total cost of ownership calculations have increased interest for non-traditional solutions. From financial and safety perspectives, low-quality materials should not be accepted, even for free.

Cost-efficient Circle & H helideck lighting solution

Unlike conventional helideck lighting fixtures, Frictape Circle & H Netlight does not require any fixed structures for lighting the helideck circle & H. This means that no holes are needed on the helideck for bolts, screws or rivets that could cause leakages or otherwise harm the deck’s structure.

The lack of fixed structures also means that Frictape Circle & H Netlight is easy to handle and store and makes helideck cleaning and maintenance effortless. Furthermore, when compared to traditional fixed solutions, the installation of Frictape Circle & H Netlight is remarkably fast, taking no more than a few days.

Frictape Circle & H Netlight consists of custom-designed light modules that are installed directly to the market-leading Frictape Landing Net. Frictape Circle & H Netlight’s uniquely designed, integrated light modules ensure that the circle & H lights are optimally visible from helicopter, making the helideck location, identification and final approach safe for pilots.

Netlight total height is always less than 2.5cm, including the lights, baseplate and the landing net. Frictape Circle & H Netlight complies with the CAP437 standard and it has a proven friction coefficient of more than 0.65cm.

All components are tested to withstand loads generated by the heaviest helicopters.

When properly tightened, the net’s light modules will not move and are always clearly visible for maximum safety.

Better helideck safety through professional testing

The purpose of standards is to state the minimum requirements. When it comes to safety, it is vital that one does not focus solely to fulfilling standards but to responding to real-life needs. It is important to ensure that the structure and strength of safety products is well balanced and the installation method should be fail-safe to ensure correct operation, this usually also results in easy and fast installation process.

Requirements for helideck safety are becoming more stringent, with the UK authorities leading the way. A crucial part of ensuring safety is to regularly test the materials for remaining strength; safety products can’t simply be installed and forgotten.