The word ‘unmanned’ is music to the ears of the oil and gas industry. Remote locations present logistical challenges, but developments in the robotics sector are driving autonomous capabilities, both underwater and on land.

Among early adopters is oil and gas major Equinor, which estimates that a broad implementation of robots and drones offers annual cost savings exceeding Nkr1bn ($99.1m).

Working with leading hardware and software developers including ANYbotics and Cognite, the company is exploring, testing and employing robots in areas including ground robotics, aerial drones, underwater drones and unmanned ships.

Magnus Rørvik Brandtzæg, senior manager of technology at Equinor, tells Offshore Technology about autonomous robotics that have already deployed across several sites, explaining that the company's strategy revolves around “the four Ds of robotics: the dull, dirty, distant and dangerous tasks”.

“In theory, these are tasks people and machines can do equally well, but we would prefer people not to do them because of the four Ds. We don't want people to go out there – it costs money, it is not efficient, it is dirty or dangerous,” he says.

Equinor’s autonomous robotic dog: the unmanned best friend

Equinor’s robotics profile includes ANYbotics’ ANYmal, an autonomous quadruped robotic ‘dog’ designed for non-explosive industrial areas. Affectionately named Roberta, one ANYmal was deployed in November 2024 at Equinor’s Northern Lights facility, which will eventually be unmanned.

Brandtzæg tells Offshore Technology that “we managed to run missions there already after just two or three days. The commissioning was short because we had already scanned the facility with LiDAR [Light Detection and Ranging] and created a 3D model with point cloud, which we sent to ANYbotics.”

The relationship with ANYbotics is long-standing and, in 2023, the company’s ANYmal X was trialled at Equinor’s Kårstø site for five weeks. Currently the only ex-certified quadruped robotic solution for zone one hazardous areas, ANYmal X precedes the 2026 release of the ANYmal XD model, which Jasmine Assefi, the company’s partnership and sales generator for oil and gas, describes as “essentially a beefed-up version”.

Roberta is specifically designed to meet the needs of challenging industrial environments, including those with harsh climates and complex terrains. The robot includes a camera able to zoom up to 20-times, which enables the reading of gauges and valve positions, as well as a thermal camera to detect overheating and identify anomalies.

It also includes gas sensing and acoustic imaging payload for detecting and locating gases like CO₂, an onboard microphone for acoustic checks, 3D LiDAR plus SLAM (Simultaneous Localisation and Mapping) for navigation and high-quality video streaming capabilities.

Roberta is engineered to be IP67-rated, making it waterproof, dust-proof and capable of operating in extreme industrial conditions including in snow, deserts and rainy environments. In the case of ex-certified ANYmal X, a temperature monitor ensures the maximum surface temperature does not pose an ignition risk, working along ex-certified components including batteries and fans.

The applications are plentiful. Roberta monitors CO₂ levels in the air and sends hazardous level alerts, but Assefi says “our robots can do so much more. ANYmals can perform regular autonomous inspection rounds and leverage the visual, thermal, acoustic and gas sensing capabilities. We can also conduct perimeter surveillance and do safety-critical monitoring; for example, during high pressure-pump tests.”

Brandtzæg calls Roberta’s deployment “a sign of early success”, noting that deployment represented a learning curve at Northern Lights. “The operators have started using it themselves and creating missions on their own, without the research and development team there,” he adds.

He acknowledges an odd hiccup: “There was one instance when it tripped and fell into a ditch; it had been cordoned off, but we hadn't put it into the mission yet – this was good learning for us, the people on the ground and for ANYbotics, which has supported in the process of deploying in the real environment.”

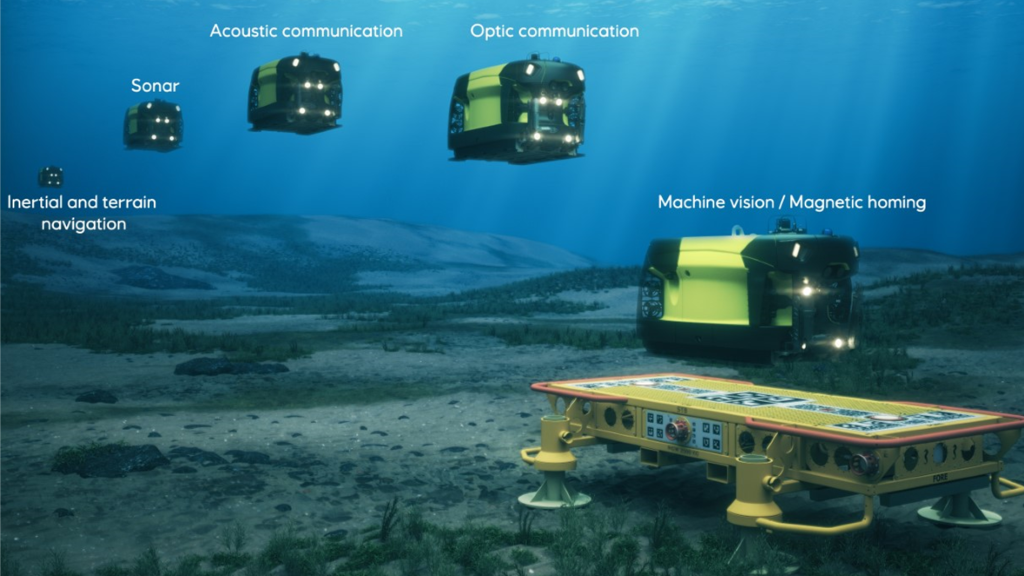

Just keep swimming: the record-holding Hydrone-R

Robotics’ potential in oil and gas goes beyond ground level, and autonomous underwater drones offer immense value to companies including Equinor, taking over some of the most difficult human tasks like inspecting underwater subsea production systems such as wellheads and pipelines, and turning valves at depth.

In 2019, Equinor awarded Saipem a ten-year contract for the use of its autonomous underwater intervention drone, Hydrone-R, and the Hydrone-W all-electric work-class remotely operated vehicle (ROV) in the Njord Field development. Worth approximately €40m ($43.74m) at the time, the contract made Equinor the first user of the technology.

Hydrone-R was deployed in 2023 and has since achieved 240 consecutive days of uninterrupted subsea residency, an industry record. The hybrid model acts both as an ROV and an autonomous underwater vehicle (AUV), recharging and communicating wirelessly via a subsea docking station.

The drone can reach depths of up to 3,000m and, when functioning autonomously as an AUV, has a range of more than 10km, compared to a 30m range as an ROV.

While the autonomous potential is huge, the technology is still young and the limits unknown. “We want to have options in the toolbox,” says Brandtzæg. “Can it be down there for a long time? Is it affected by [marine] growth? How far can it travel? Can it inspect pipelines going from shore to offshore, between facilities? How can it be combined with unmanned vessels, in combination with drones?”

Among other applications, Hydrone-R performs regular drill support, supports production activities and relays information about potential leaks. “Currently, it is more about inspecting the integrity of the plant and being present at the seabed with eyes on our facilities,” explains Brandtzæg. “Moving forwards, it will be more about manipulation, like turning the valves, as we do with an ROV presently. In the future, we will do that with underwater drones as well.

“Hydrone-R was the first step of this journey, using underwater drones to do more and more,” he adds.

Hyrdrone-W has not yet been taken into operations but is expected to be introduced in 2026, in place of the Kystdesign support Equinor currently uses.

‘Autonomous’ is the cardinal term, and developments in autonomous underwater drones offer distance and longevity in unmanned operations that promise to transform remote, emissions-heavy operations.

Tethered ROVs require human operation, usually on large, manned vessels, but Brandtzæg explains that, for Equinor, “the goal and the business case is to change how we carry out tasks. We are going from larger, heavier, more expensive vessels with higher emissions to smaller vessels like unmanned ships and underwater drones.

“For the tasks where it is appropriate, it will be cheaper, produce fewer emissions and free up time for those larger, more complex vessels to do the tasks that only they can do.”

The human-machine relationship

Removing humans from the ‘four Ds’ includes substituting them for robots in some of the most dangerous environments. Equinor is particularly enthusiastic about developments in explosive atmosphere (ATEX) capabilities, which would reduce risk for humans in zones zero to two (where an explosive gas is or could be present).

“ATEX capabilities in robotics enables us to actually take them offshore and create value in our operations,” says Brandtzæg.

Equinor has also piloted robots for other potentially dangerous tasks including welding and sandblasting at its Mongstad site. Robot-carrying robots can safely ferry their automated colleagues to dangerous environments, and Equinor has already used one robot to deliver a welding robot into the flare stack.

Robotics can offer efficiency and accuracy beyond human achievability, Brandtzæg notes. “Robots don't just say something is hot, cold, vibrating or making a sound – they can tell you the exact temperature and see the trending, such as reporting a one degree increase over a week. They can also report the frequency spectrum of a noise and assess what type of bearing fault there could be, just based on the sound or vibrations.

“With robots, there is efficiency, frequency, repeatability and precision,” he stresses.

Equinor is enhancing the value of precision using AI and data analysis. Roberta, for instance, analyses videos using Equinor’s in-house algorithm to calculate the percentage of oil left in the glass of non-instrumented pumps and identify potential leaks. Similarly, it uses a computer vision algorithm to detect fence perimeter faults.

When it comes to adding value to Equinor’s operations, the future is in versatile and autonomous robotics. “Roberta at Northern Lights is a general-purpose inspection robot walking around and inspecting with a high level of autonomy, rather than carrying out one specific task, like our other remotely controlled robots,” says Brandtzæg.

“I see this as a potential development in the future: capabilities will be one dimension, and then autonomy will be the other.”