Services Provided by BPT

BPT provides the following services.

Modelling

- Fluid definitions / PVT modelling

- Steady state models

- Dynamic / transient models

- Allocation models

- Cause and effects matrix

- Integrated solutions well, pipelines and topside or subsea processing

Flow assurance

- Steady state and transient multiphase hydraulic analysis

- Hydrates and chemical requirements for hydrate prevention / mitigation

- Erosion and wax studies

- Slugging

- Depressurisation

- Pigging

- Operational procedures

- Commissioning and RFO procedures

Process design / verification

- Field process development assistance

- Fluid compatibility evaluations (wax, asphaltenes, hydrates, naphtenates)

- Fluid re-characterization and tuning

- Compressor and ASV requirements

- Separators and scrubbers sizing / verification / evaluation

- Control valves, pressure safety valves and orifices

- MEG regeneration and reclaiming systems

- Capacity evaluations and de-bottlenecking

Well studies

- Steady state thermal hydraulic analyses for field life conditions

- Transient analysis for shut down and restart

- Well testing and clean-up

Process safety

- Overpressure protection design and verifications, pipelines and topside

- Primary and secondary barrier evaluations

- Relief and blowdown studies

- Flare system capacity

- HIPPS design and verification

- PSD logic

- Cause and effect evaluation

- Hazid assistance

- Hazop assistance

Process control

- Development / verification of control strategies

- PID regulator tuning

- Sizing of control valves

- Compressor protection evaluations

Operator training systems

- Operator training simulator in partnership with RSI

Commissioning / start-up / operation

- Verification / development of procedures

- Plant start-up

- Studies and preparations

- Field assistance and troubleshooting

- Verification / development of commissioning procedures

- Commissioning planning and supervision

Software development

- Automated steady state production profile calculations

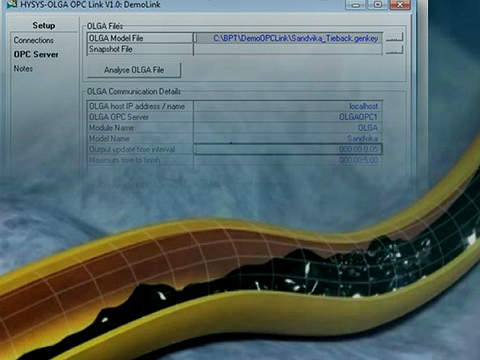

- OPC link developments

- Development of HYSYS user variables

- Development of extensions

- MySep™ integration

- Automated data extraction

- Tailored VBA

Training (is provided to users of BPT deliveries)

- Steady state, dynamic and integration with OLGA™

- Efficient use of simulation tools

- Work process development